Charcoal fire heating secondary puerarin tablet dryer and application method thereof

An application method, a secondary drying technology, which is applied in the direction of drying machine, drying, progressive drying machine, etc., can solve the problems of poor shape, easy contamination of kudzu root slices, and lower quality of kudzu root slices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

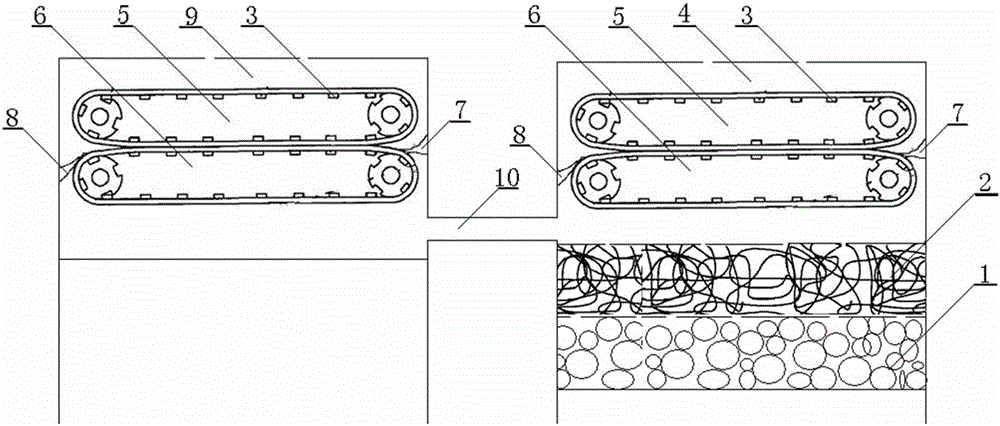

[0020] Example 1, such as figure 1 As shown, a charcoal-fired secondary Pueraria lobata dryer includes a charcoal-fired heating chamber 1, a filter chamber 2 located above the charcoal-fired heating chamber 1, and a primary drying chamber 4 located above the filter chamber 2 , A secondary drying chamber 9 connected to the primary drying chamber 4 through a heat conduction channel 10. The filter chamber 2 is filled with a filter screen, and the charcoal heating chamber 1 and the filter chamber 2 and between the filter chamber 2 and the primary drying chamber 4 are communicated through pores, and the secondary drying chamber 9 is provided A through hole communicating with the outside world is provided above the secondary drying chamber 9; the primary drying chamber 4 and the secondary drying chamber 9 are respectively provided with a first conveyor belt 5 and a first conveyor belt 5 corresponds to the parallel second conveyor belt 6 up and down. The first conveyor belt 5 and the...

Embodiment 2

[0021] Embodiment 2. The difference between embodiment 2 and embodiment 1 is that the through hole on the second drying chamber in embodiment 2 is located above the discharge port 8, and the discharge port 8 and the heat conduction channel 10 are respectively located on the conveyor belt On both sides. Permanent magnets 3 are arranged on the first conveyor belt 5 in the first drying chamber and the second drying chamber, the permanent magnets 3 are distributed at equal intervals, and the lower part of the second conveyor belt 6 is provided with iron sheets. The second conveyor belt 6 is longer than the first conveyor belt 5 by 2 meters, and the first conveyor belt 5 is located in the middle of the second conveyor belt 6.

[0022] The application method of the present invention: when working, heat the charcoal fire, preferably using smokeless coke as the fuel. When the charcoal fire does not smoke, the hot air enters the first drying chamber through the filtration of the filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com