An uninterrupted calcium carbide furnace waste heat recovery control system and method

A waste heat recovery and control system technology, which is applied in the steam generation method using heat carrier, indirect heat exchanger, furnace, etc., can solve the problem of continuous utilization of waste heat, and achieve real-time control, effective and orderly control system, and steam power generation Take advantage of reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

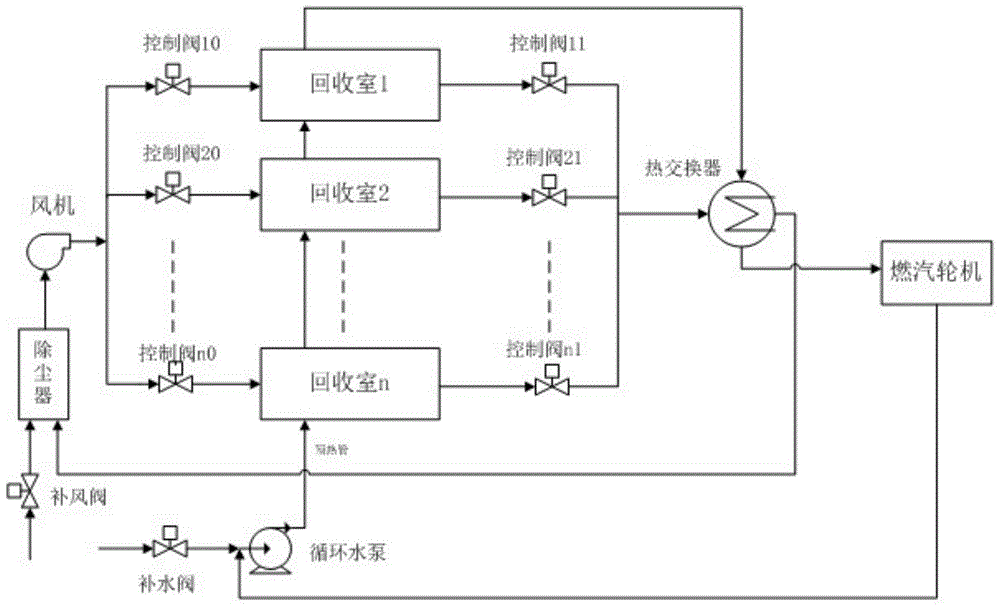

[0045] Embodiment 1: as figure 1 It is a schematic diagram of the waste heat recovery power generation system designed in the present invention, which mainly includes a fused carbide sealed waste heat recovery chamber, a cooling and circulating air device, a hot water and steam cycle device, and a steam turbine power generation device.

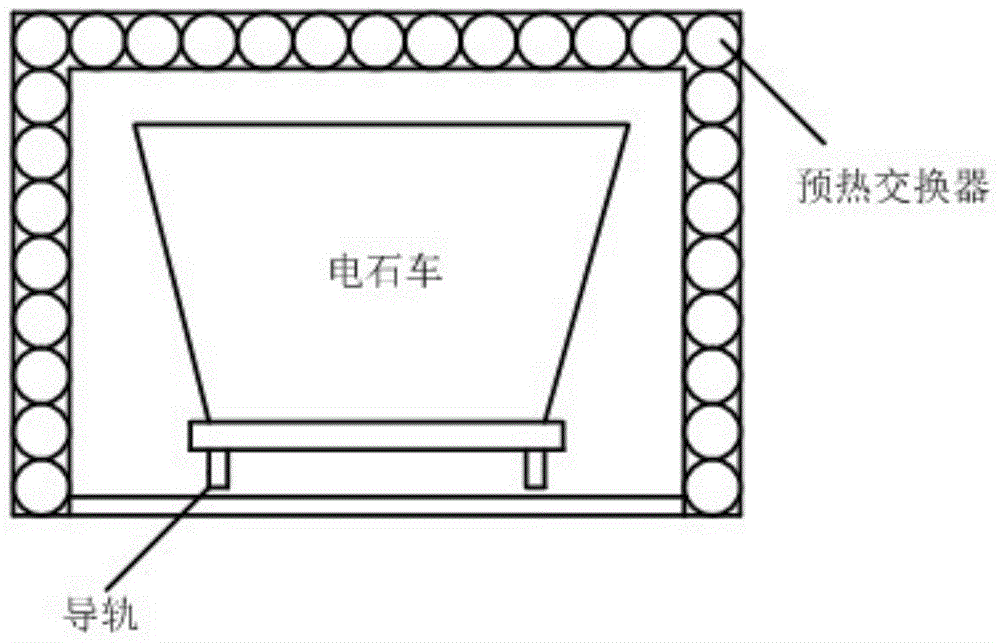

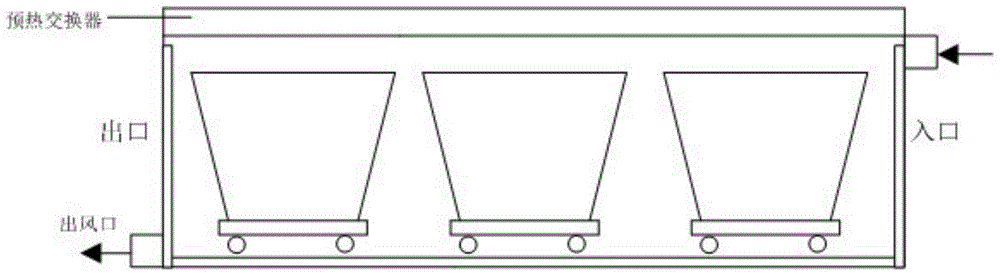

[0046] The processed molten calcium carbide is loaded on the calcium carbide carrier vehicle and transported to the sealed waste heat recovery chamber through rails. Sealed waste heat recovery chamber such as figure 2 As shown in the side sectional view, the two ends of the sealed chamber are sealed doors, one end is the inlet and the other is the outlet, and the bottom is the track, which can be conveniently practiced by pulling in and out of the fused calcium carbide carrier vehicle. Wall heat exchangers are installed at the front, rear and upper door of the sealed waste heat recovery chamber, which can absorb heat, transfer the waste heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com