A plate forming limit diagram testing device and method thereof

A sheet metal forming and testing device technology, applied to measuring devices, applying stable tension/pressure to test material strength, analyzing materials, etc., can solve problems such as inability to accurately test critical cracking strain, and achieve the effect of simple structure and principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

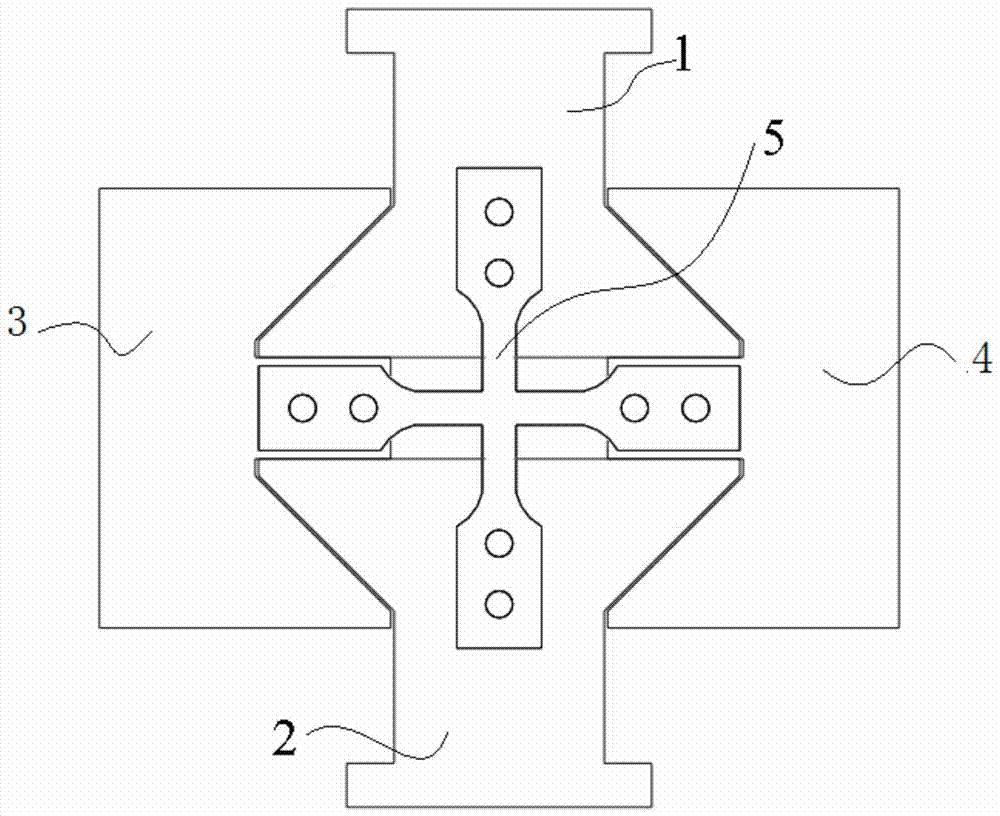

[0049] A plate forming limit diagram testing device includes an upper wedge template 1 , a lower wedge template 2 , a left wedge template 3 and a right wedge template 4 for installing a test piece 5 .

[0050] see figure 1 , the upper wedge template 1, the lower wedge template 2, the left wedge template 3 and the right wedge template 4 are combined together.

[0051] The lower end surface of the upper wedge formwork 1 is a plane, and the upper end surface of the lower wedge formwork 2 is a plane.

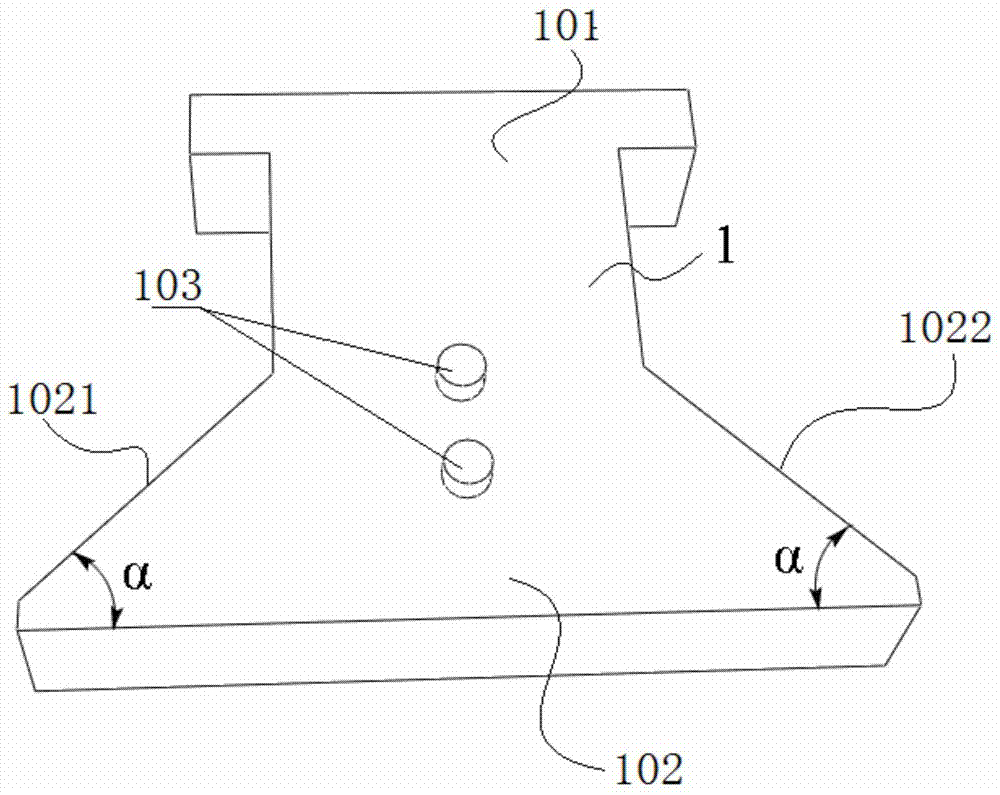

[0052] There is a working plane on the left and right sides of the upper wedge-shaped formwork 1, and the included angles between these two working planes and the lower end surface of the upper wedge-shaped formwork 1 are both α.

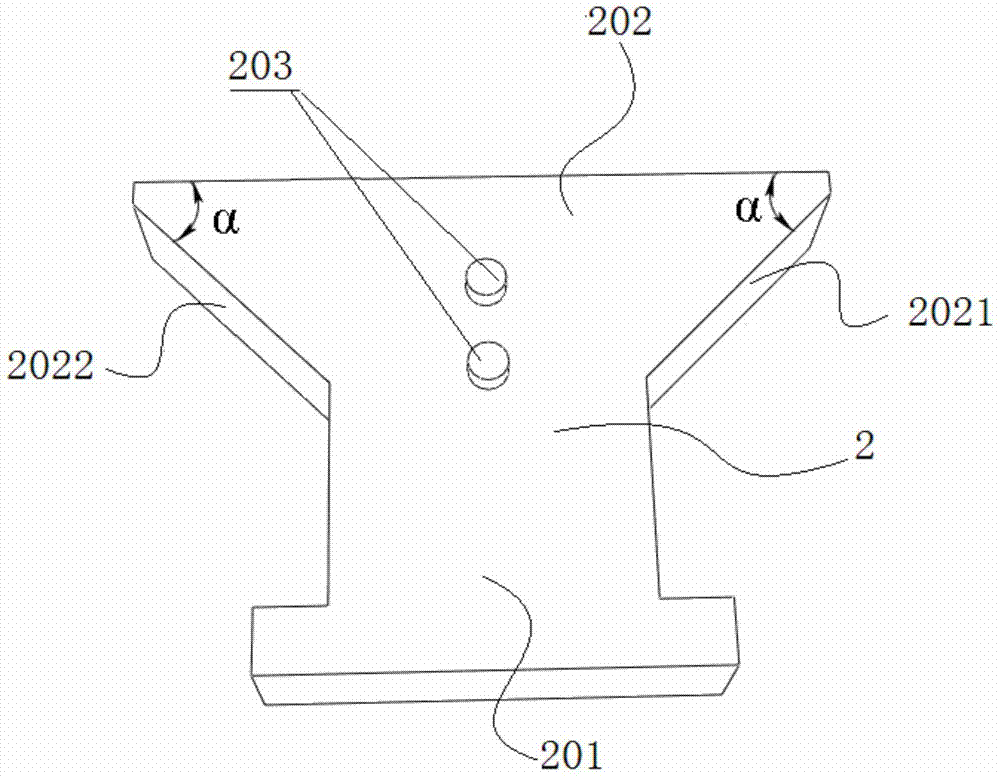

[0053] There is a working plane on the left and right sides of the lower wedge formwork 2, and the included angles between these two working planes and the upper end surface of the lower wedge formwork 2 are both α.

[0054] There are two triangular groov...

Embodiment 2

[0061] A plate forming limit diagram testing device includes an upper wedge template 1 , a lower wedge template 2 , a left wedge template 3 and a right wedge template 4 for installing a test piece 5 .

[0062] The upper wedge formwork 1 and the lower wedge formwork 2 have the same shape. The left wedge template 3 and the right wedge template 4 have the same shape.

[0063] The upper wedge-shaped template 1, the lower wedge-shaped template 2, the left wedge-shaped template 3 and the right wedge-shaped template 4 are assembled together.

[0064] Both sides of the upper wedge formwork 1 cooperate with the left wedge formwork 3 and the right wedge formwork 4 respectively. Both sides of the lower wedge template 2 cooperate with the left wedge template 3 and the right wedge template 4 respectively.

[0065] The test piece 5 is in the shape of a "cross", and its branches are respectively fixed on the upper wedge template 1, the lower wedge template 2, the left wedge template 3 and ...

Embodiment 3

[0070] A plate forming limit diagram testing device includes an upper wedge template 1 , a lower wedge template 2 , a left wedge template 3 and a right wedge template 4 for installing a test piece 5 . These stencils are all metal plates with the same thickness. The shape of the template referred to in this embodiment refers to the shape of each metal plate surface.

[0071] see figure 1 , the upper wedge-shaped formwork 1 and the lower wedge-shaped formwork 2 have the same shape and the size of each part, and the two are placed symmetrically up and down. The shape and size of each part of the left wedge-shaped template 3 and the right wedge-shaped template 4 are the same, and the two are placed symmetrically.

[0072] The upper end of the upper wedge-shaped template 1 is a connecting handle I101, and the lower end is an isosceles trapezoidal plate I102, which means that the shape of the upper wedge-shaped template 1 is similar to the Chinese character "mountain". see figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com