Frequency multiplication conversion apparatus for realizing temperature regulation of large-caliber crystals in vacuum environment

A technology of vacuum environment and crystal temperature, used in laser cooling devices, light demodulation, laser parts and other directions, can solve the problem of inability to achieve precise temperature control of large-diameter crystals, and ensure frequency doubling conversion efficiency and simple control method. , the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

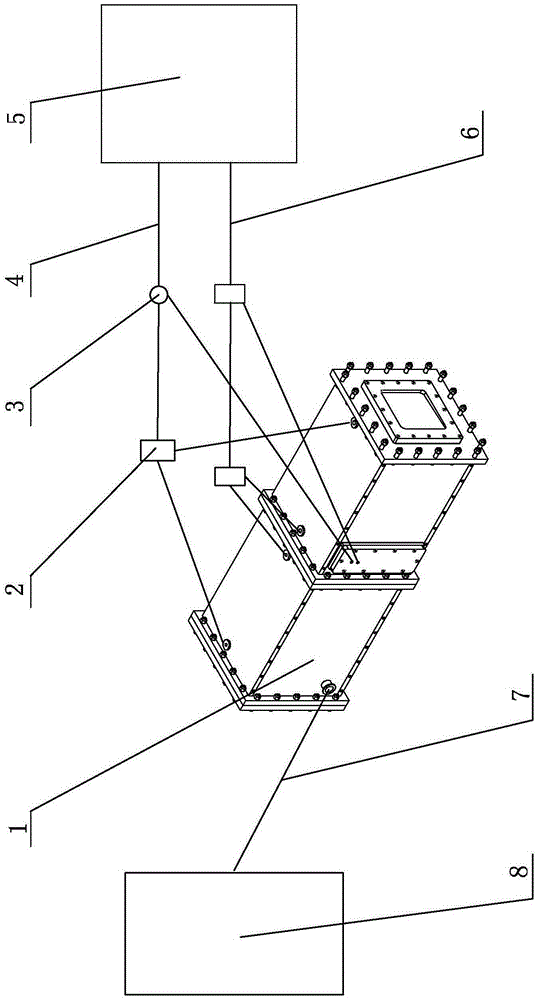

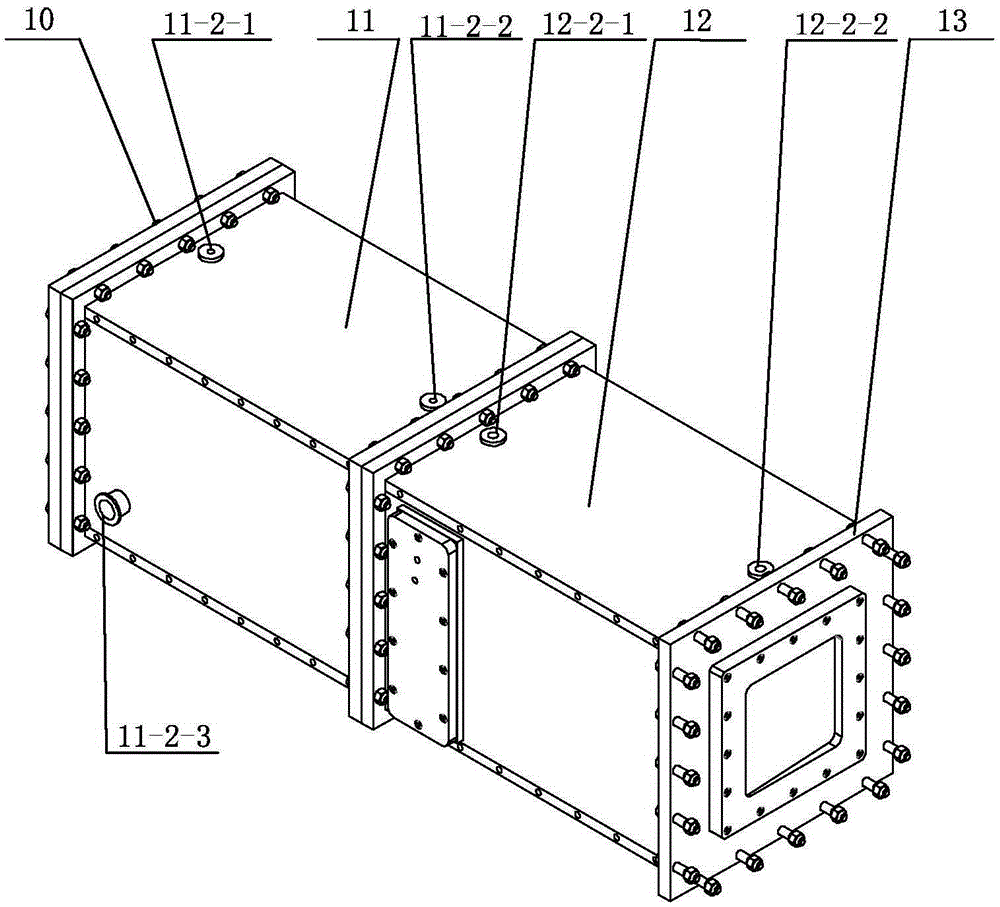

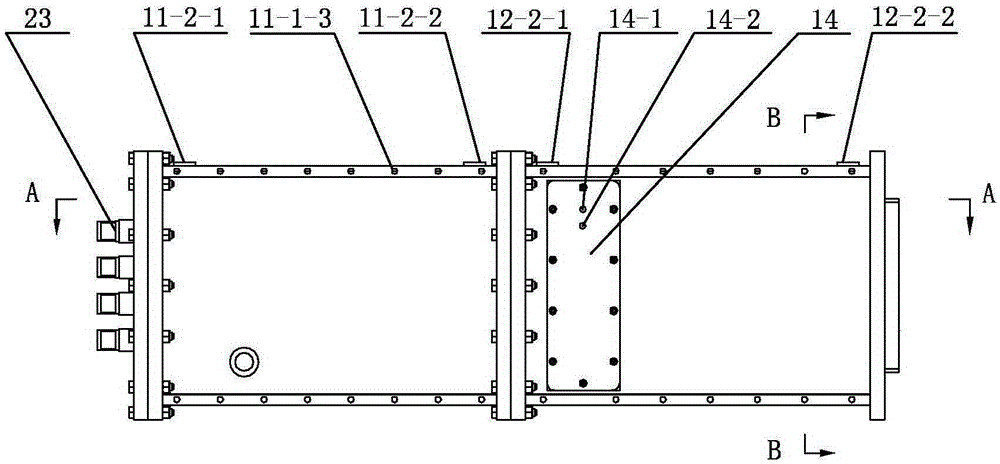

[0009] Specific implementation mode one: combine Figure 1 to Figure 9 To illustrate this embodiment, the large-diameter crystal frequency multiplication conversion device described in this embodiment includes a main body 1, a water flow control valve 3, a water inlet pipe 4, a constant temperature water tank 5, a return water pipe 6, a vacuum tube 7, a vacuum machine 8, and a large-diameter crystal Frequency multiplication mechanism 9 and a plurality of water pipe joints 2, the main body 1 includes a first end cover 10, a first box body 11, a second box body 12 and a second end cover 13, one end of the first box body 11 is connected to the first The end cover 10 is sealed and connected, the other end of the first box body 11 is detachably connected to one end of the second box body 12, the other end of the second box body 12 is provided with a second end cover 13, and the large-diameter crystal frequency doubling mechanism 9 is provided Between the first box body 11 and the s...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 6 and Figure 7 Describe this embodiment. The large-diameter crystal frequency doubling mechanism 9 in this embodiment includes a fixed frame 15 and a crystal frame 16. The crystal frame 16 is slidably inserted into the fixed frame 15. The crystal frame 16 is provided with a crystal temperature control channel 16. -1, the crystal temperature control channel 16-1 communicates with the third water inlet 14-1 and the third water return port 14-2 respectively. A large-diameter crystal is fixed in the crystal frame 16, and the surface temperature uniformity of the surface temperature of the large-diameter crystal can be better controlled by setting the crystal temperature control channel 16-1. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 4 , Figure 6 and Figure 7 To illustrate this embodiment, the crystal temperature control channel 16 - 1 in this embodiment communicates with the third water inlet 14 - 1 and the third water return port 14 - 2 respectively through the vacuum bellows 22 . With this arrangement, since the vacuum bellows 22 has good sealing performance and good flexibility, it can not only ensure the vacuum state in the main body 1, but also ensure the accuracy of the movement mechanism of the large-diameter crystal frequency doubling mechanism 9 during movement. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com