Camera module automatic testing system and camera module automatic testing method

An automatic test system and camera module technology, which is applied in image communication, television, electrical components, etc., can solve the problems of increasing the number of lens installations and the investment of equipment, complex testing process, and inability to guarantee the reliability of test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

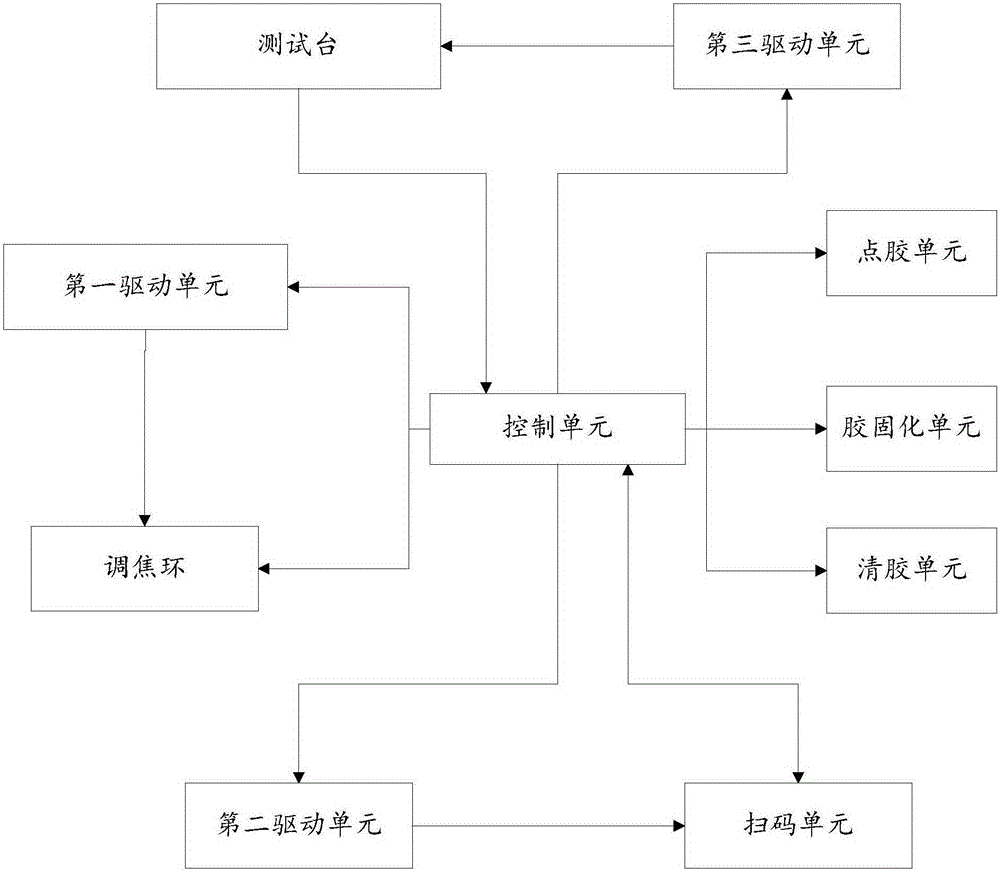

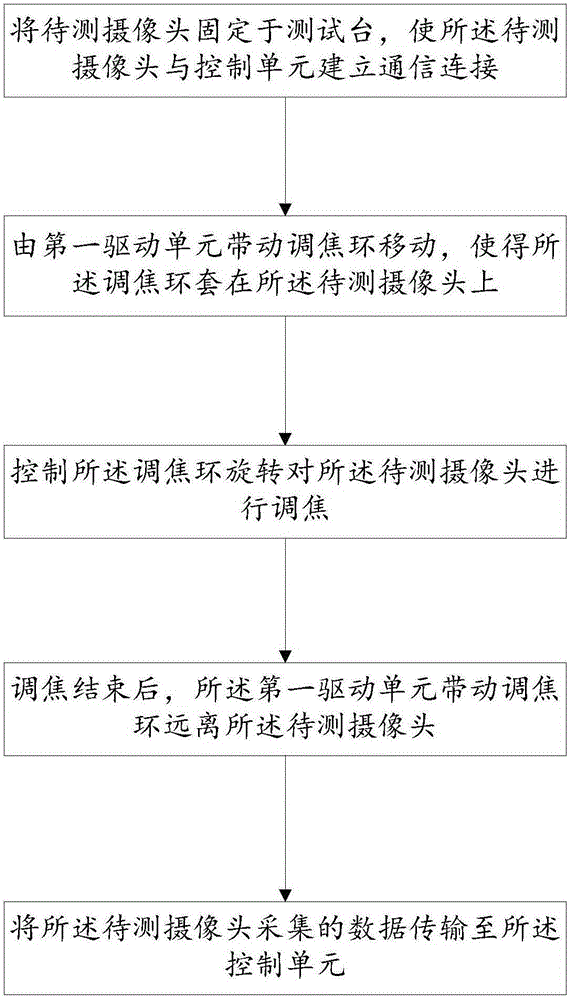

[0039] In the first embodiment, as in figure 1 As shown, a camera module automatic test system includes a test bench, a control unit, a first drive unit, a focus ring, a second drive unit, a code scanning unit, a third drive unit, a glue dispensing unit, a glue curing unit and Glue cleaning unit, wherein the first drive unit is connected with the focusing ring, the second drive unit is connected with the code scanning unit, the third drive unit is connected with the test bench, and the control The unit is used to receive data, perform data processing and control the first drive unit, the focus ring, the second drive unit, the third drive unit, the glue dispensing unit, the glue curing unit and the glue cleaning unit Move, thereby realizing the automatic test to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com