Organic light-emitting device and method for manufacturing same

An organic and light-emitting unit technology, applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as the reduction of aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, exemplary embodiments of the present invention will be described in detail.

[0042] In organic light-emitting diode (OLED) technology, the encapsulation process is the core technology that determines the lifetime and reliability of OLEDs, and OLED materials can cause various problems, such as inducing deformation of organic material layers and electrodes and Lifespan decline, which is caused by the characteristics of OLED materials that are extremely intolerant to moisture and oxygen. Therefore, in OLEDs, an encapsulation step that blocks external air is absolutely necessary.

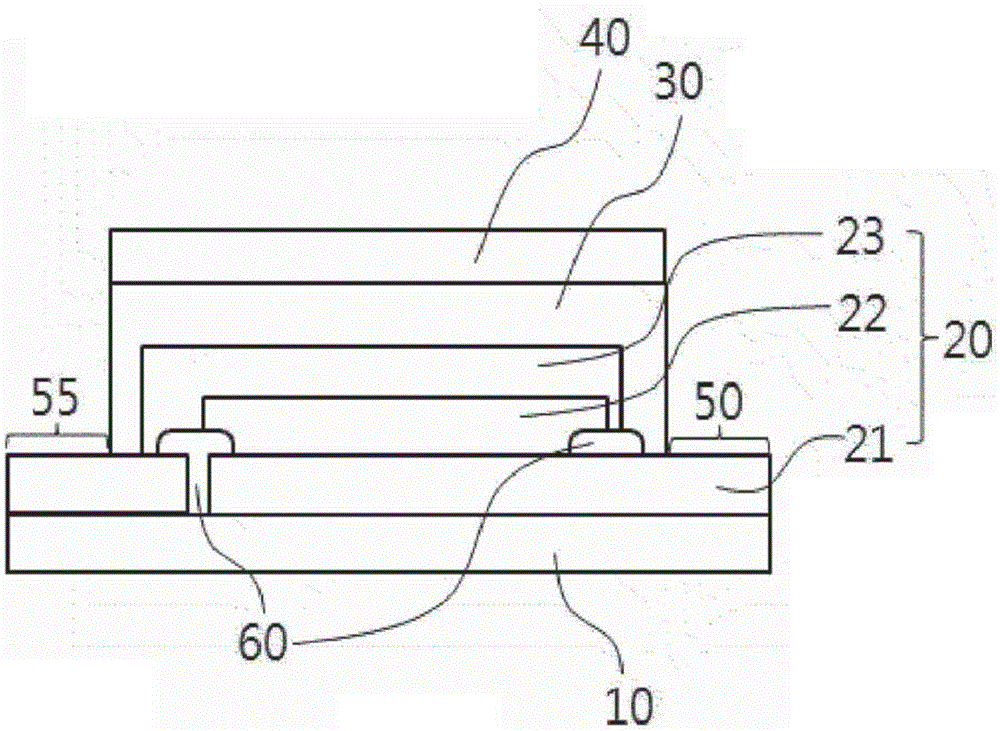

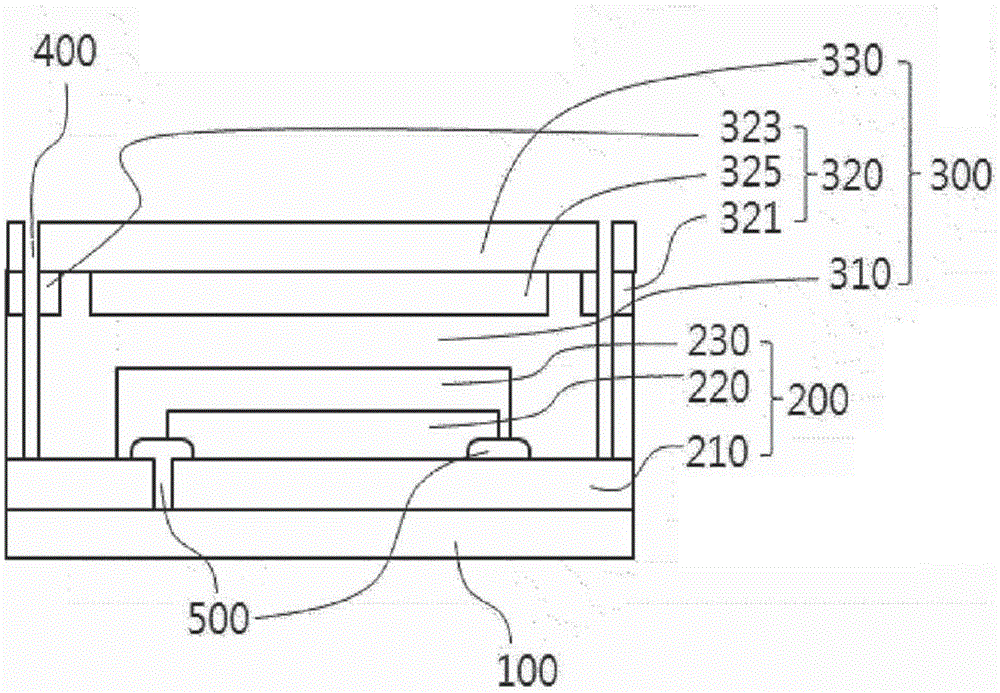

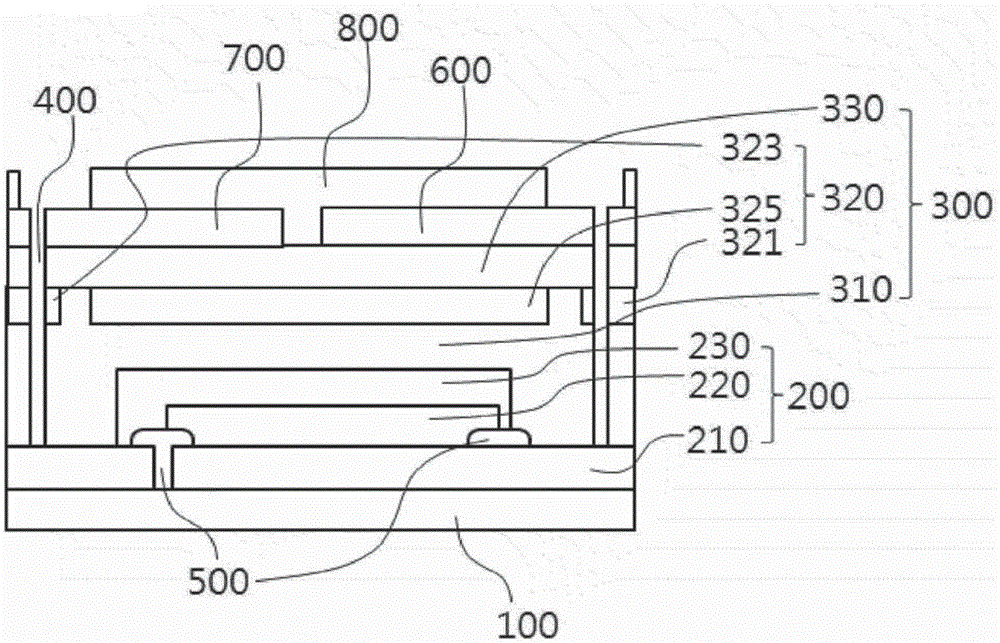

[0043] An organic light emitting diode in the related technical field and a manufacturing method thereof are schematically illustrated in figure 1 and Figure 4 middle. In the organic light emitting diode of the related art, in order to expose the electrode pad ends 50 and 55, a method of cutting the sealing layer 30 and laminating the sealing layer 30 on the organic light emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com