Air column enclosure device for suspension and tensioning installation and manufacturing method

A manufacturing method and air column technology, applied in the direction of botany equipment and methods, applications, climate change adaptation, etc., can solve the problems of cavity structure damage, air leakage, collapse under pressure, and many inflated cavities, so as to avoid potential safety hazards , the effect of avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

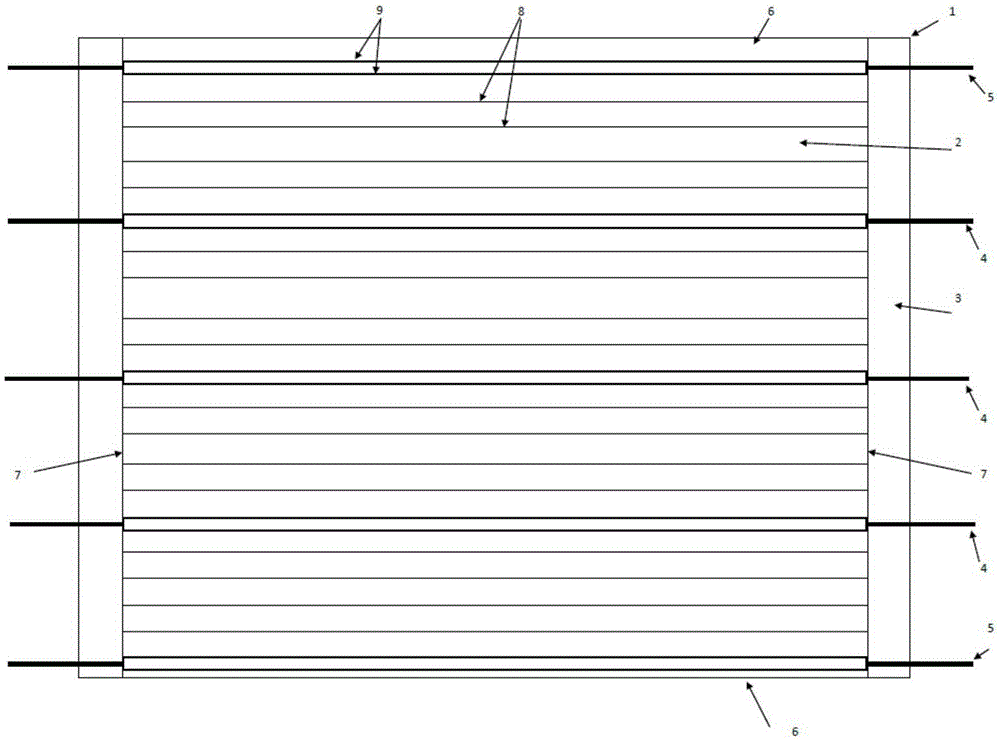

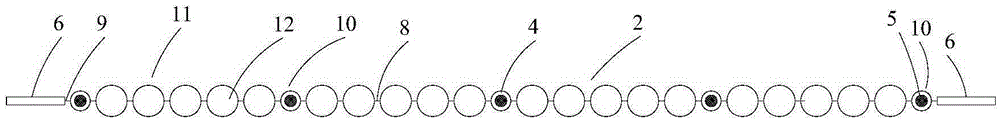

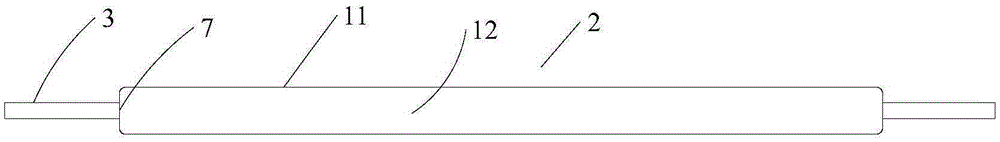

[0088] see Figure 1-Figure 7

[0089] The air column containment device 1 for suspension and tension installation provided in this embodiment includes an air column structure 2, a diaphragm structure 3, a cable 1 4 and a cable 2 5;

[0090] The air column structure 2 includes a plurality of airtight air column cavities 12, which are arranged in parallel and connected in one piece, and are in a sheet-like arrangement after being inflated;

[0091] The diaphragm structure 3 includes two groups, the diaphragm structure 3 is a single-layer or multi-layer strip film material, and the strip film materials of the two groups of the diaphragm structure 3 are respectively arranged on the air column structure 2, the elongation direction of the strip-shaped membrane material is perpendicular to the elongation direction of the air column structure 2, and the strip-shaped membrane material is integrally connected with the air column structure 2;

[0092] The first cable 4 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com