A Digital Radial Drilling Machine

A radial drilling machine, digital display technology, applied in the parts of the boring machine/drilling machine, boring/drilling, large fixed members, etc., can solve the problems of poor function, backward control system, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

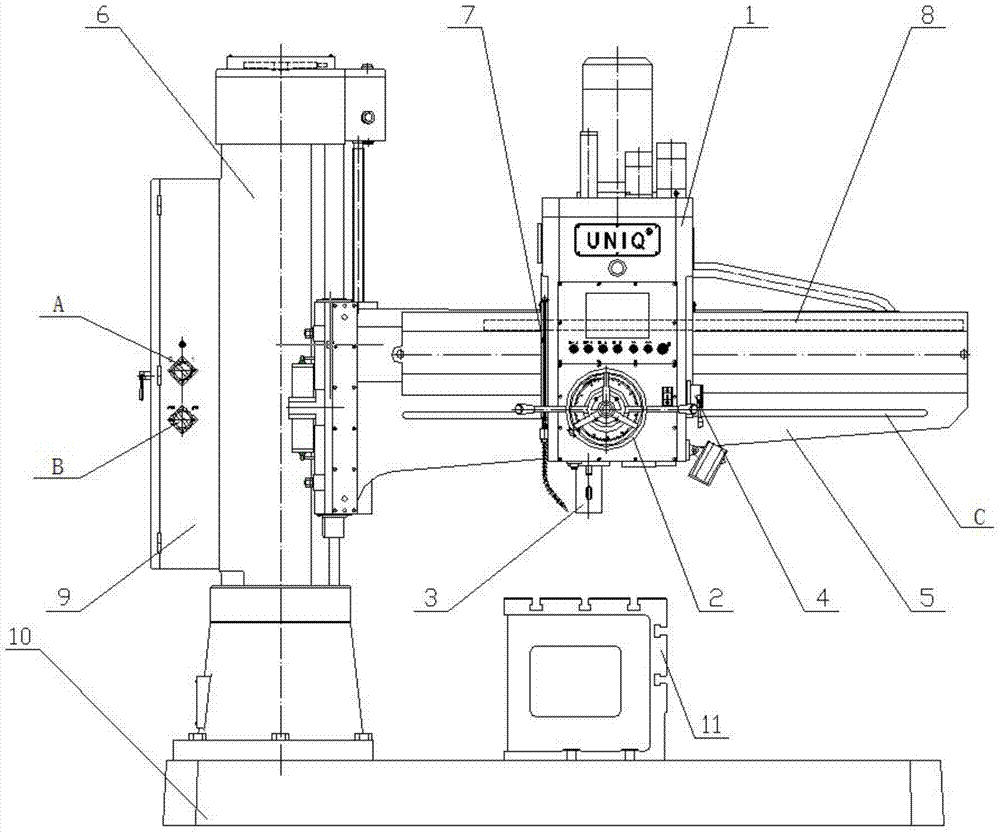

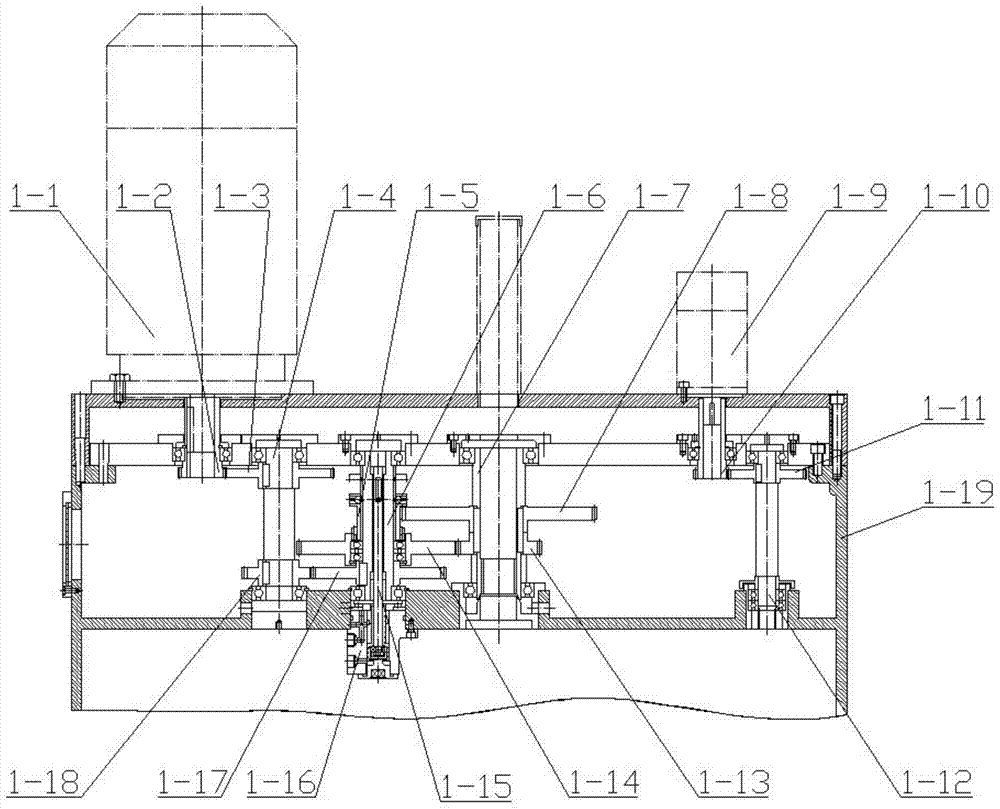

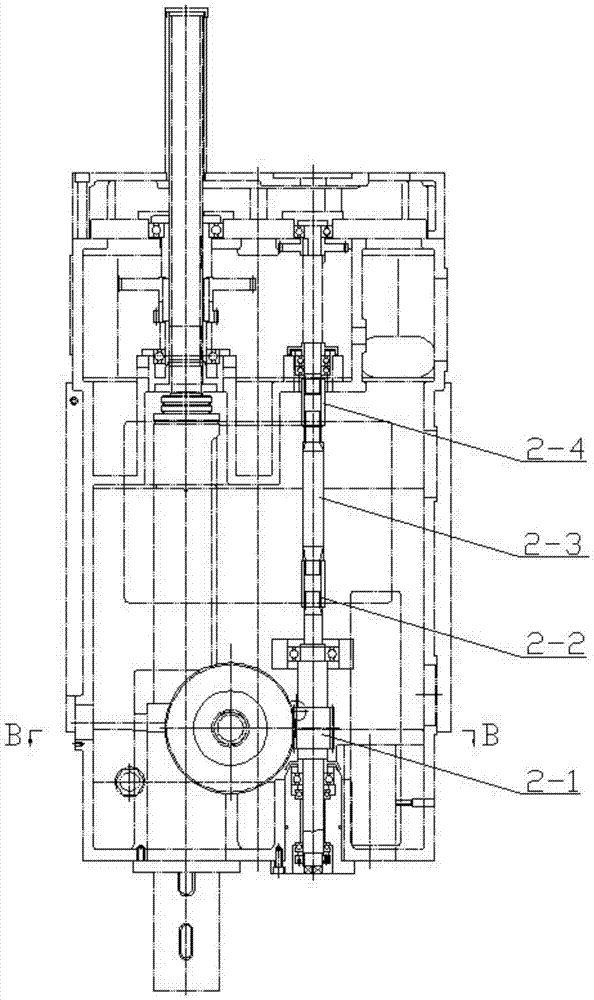

[0041] Referring to the accompanying drawings, a digital display radial arm drilling machine includes a spindle speed change and spindle feed speed change system 1, a spindle feed mechanism 2, a spindle and a balance mechanism 3, a spindle forward and reverse and a speed change control mechanism 4, a rocker arm and a clamp Tightening mechanism 5, column and rocker lifting mechanism 6, hydraulic and cooling system 7, measurement system 8, digital display control system 9, machine base 10, workbench 11, machine base 10 is fixed on the cement foundation by anchor bolts, Workbench 11 is set on the support 10, column and rocking arm lifting mechanism 6 are installed and fixed on the support 10, rocking arm and clamping mechanism 5 are installed on the rectangular guide rail square outer column 6-3 of column and rocking arm lifting mechanism 6, The digital display control system 9 is installed on the column and the rectangular guide rail square outer column 6-3 of the rocker arm lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com