Airflow-assisted abrasive flow polishing method for internal cylindrical surface

A processing method and abrasive flow technology, which are applied in grinding/polishing equipment, machine tools with surface polishing, metal processing equipment, etc., can solve the problems of unsuitable polishing of the inner wall surface of cylindrical workpieces, insignificant effects, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

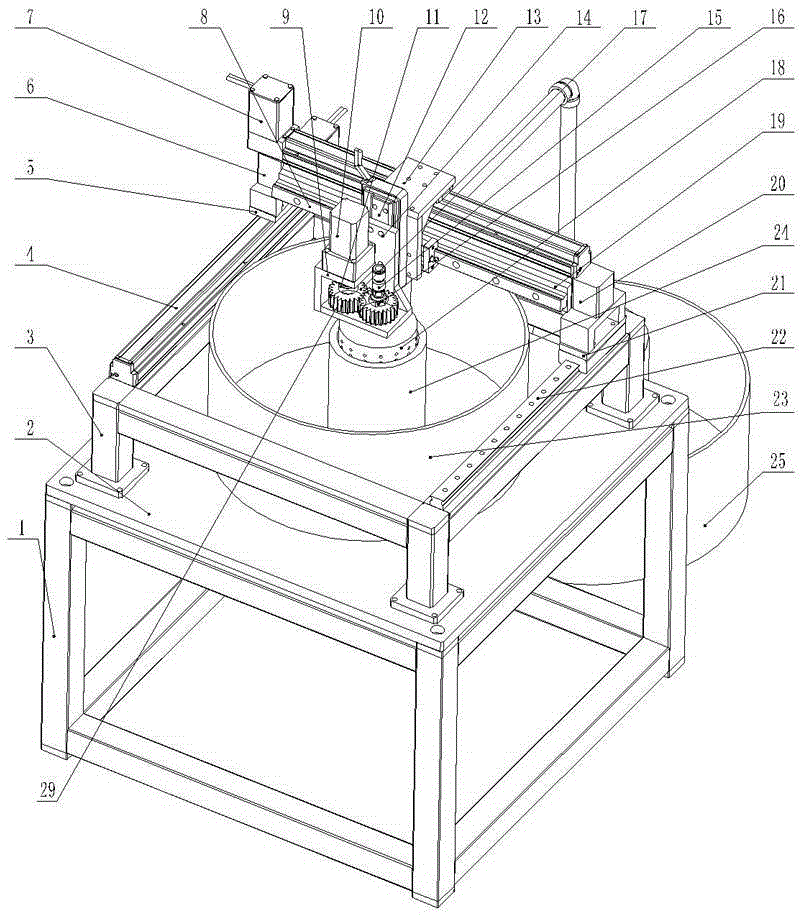

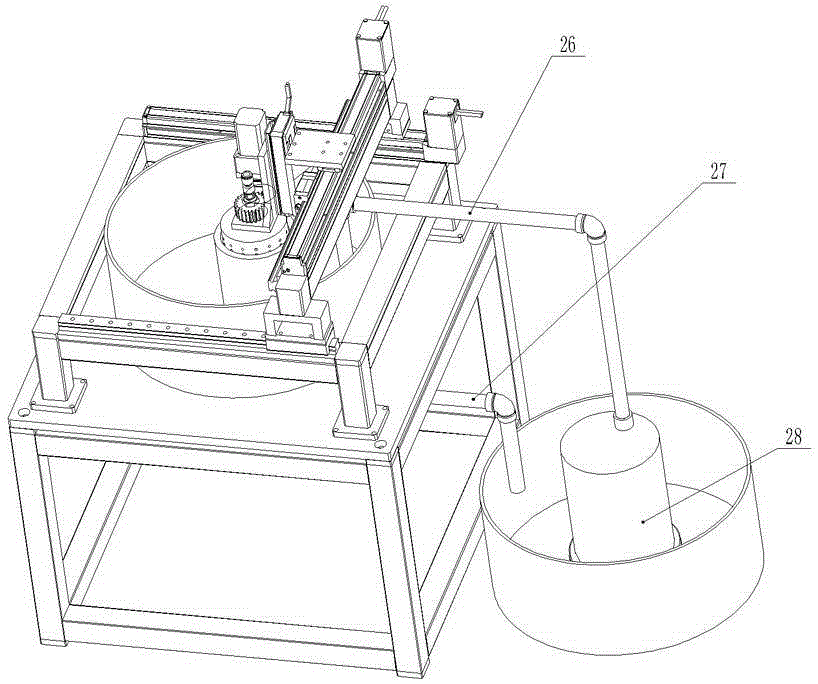

[0033] In conjunction with the accompanying drawings, the present invention will be described in detail below.

[0034] The inner cylindrical surface airflow assisted abrasive flow polishing processing method of the present invention comprises the following steps:

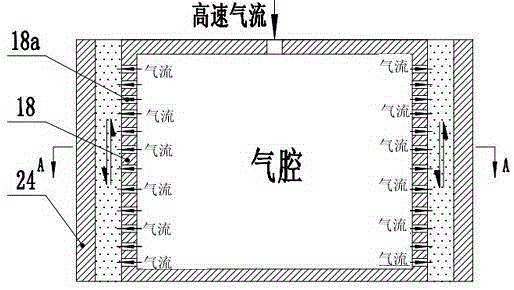

[0035] 1) Fix the circular tube-shaped workpiece 24 in the processing liquid storage tank 23, nest the cylindrical polishing tool 18 in the circular tube-shaped workpiece 24, and clamp the cylindrical polishing tool 18 at the end of the three-axis servo system , the threaded hole joint at the top of the cylindrical polishing tool 18 is connected with the output shaft of the servo motor;

[0036] 2) Start the precision three-axis servo drive system, slide the X-axis linear guide rail 22 on the X-axis precision servo drive slide table 4, until the cylindrical polishing tool 18 and the round tubular workpiece 24 reach the set distance in the X-axis direction, Then by adjusting the position of the Y-axis linear guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com