Continuous production line for single-paper preprinted color box corrugated boards and technological process of continuous production line

A corrugated cardboard and sheet-fed technology, applied in the direction of mechanical processing/deformation, can solve the problems of high humidity of cardboard, unreachable cartons, high cost, etc., and achieve the effect of improving compressive strength, reducing humidity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

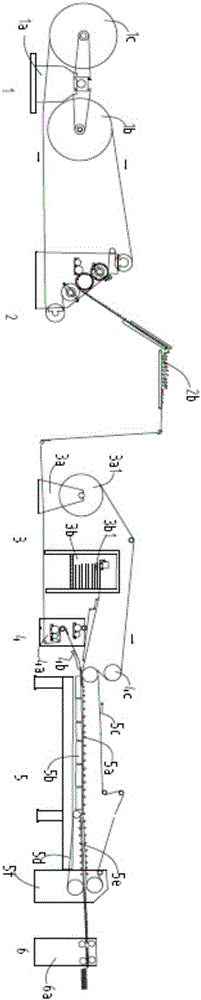

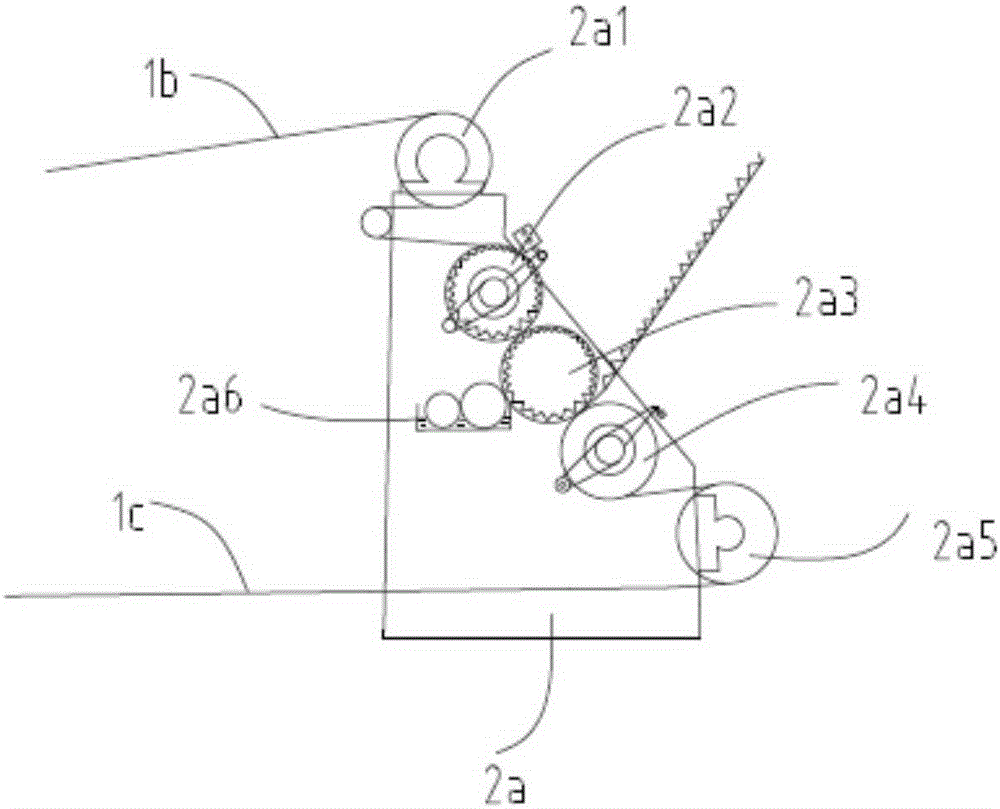

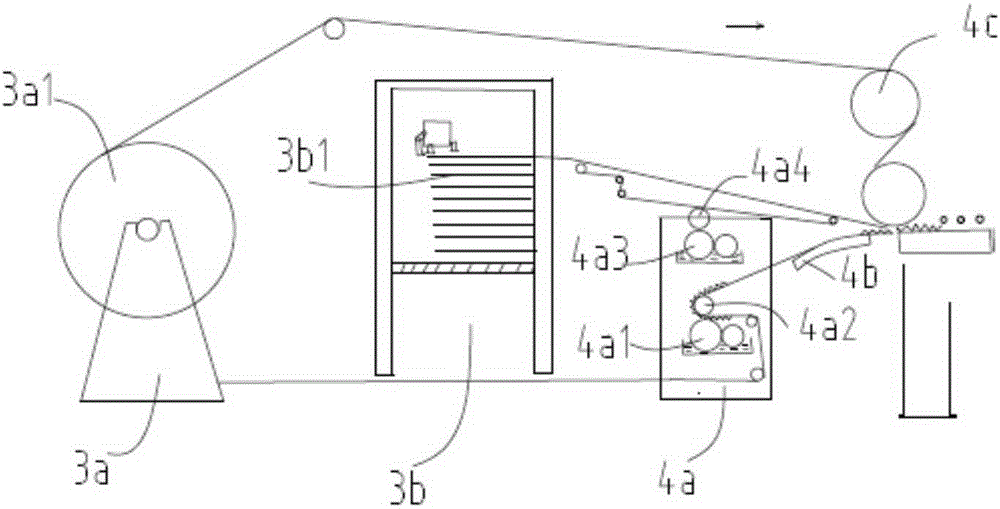

[0022] figure 1 Schematic diagram of continuous single-fed paper pre-printed color box corrugated cardboard production line, figure 2 Schematic diagram of the corrugating machine, image 3 Schematic diagram of the tissue conveying part, Figure 4 The schematic diagram of the double-layer glue machine. Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, what is provided in this embodiment is a continuous sheet-fed pre-printed color box corrugated cardboard production line and its process flow, including a raw paper conveying part 1, a raw paper rack 1a, a corrugated paper 1b, a lining 1c, and a corrugating unit part 2. , Corrugating machine 2a, conveying bridge 2b, tissue paper conveying part 3, tissue paper rack 3a, sheet feeder 3b, double layer gluing machine part 4, double gluing machine 4a, preheating plate 4b, preheating roll Cylinder 4c, bonding steaming part 5, pressing roller 5a, steam hot plate 5b, cotton webbing a5c, facial tissue b5d, supporting roller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com