High-speed EMU composite material underbody equipment cabin floor

A composite material and equipment cabin technology, applied in the field of high-speed motor vehicle composite material vehicle bottom equipment cabin floor, can solve the problems of metal outer skin thermal stress equipment cabin floor debonding, complex load conditions, panel degumming, etc., to achieve easy daily maintenance Maintenance, reduced assembly cost, and fewer assembly parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

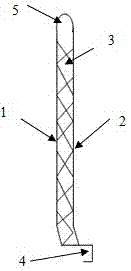

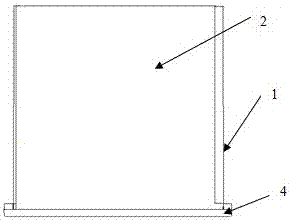

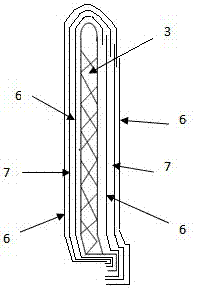

[0025] A standard EMU composite material undercarriage equipment bilge, such as figure 1 , figure 2 As shown, including the outer skin 2, the inner skin 1, the middle foam interlayer 3 and the hook 4, the outer skin 2 and the inner skin 1 are made of carbon fiber twill fabric and carbon fiber unidirectional fabric as raw materials and formed by vacuum introduction process, and the middle The foam interlayer 3 adopts PVC sandwich foam as raw material and is formed by vacuum introduction process. The PVC sandwich foam includes a foam body part and an edge part located at the edge of the body part; the outer skin 2, the inner skin 1, and the middle foam interlayer 3 The common end is provided with a hook 4, and the hook 4 is made of carbon fiber twill fabric and carbon fiber unidirectional fabric and formed by vacuum introduction process.

[0026] The outer skin 2 and the inner skin 1 use carbon fiber twill fabric and carbon fiber unidirectional fabric as raw materials, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com