Method for improving reactivity of dissolving pulp for viscose

A reactive performance, viscose fiber technology, applied in the direction of cellulose pulp post-treatment, fiber raw material treatment, artificial filament made of viscose, etc., can solve the problem of low reactive performance of dissolving pulp, to improve the reactive performance, ensure The effect of physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

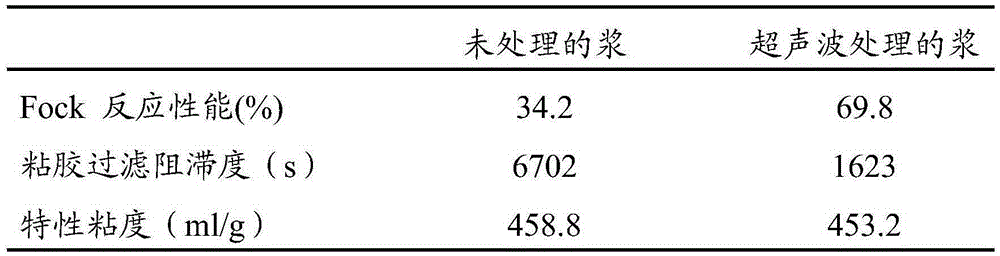

[0038] Example 1: Poplar pre-hydrolyzed sulfate dissolving pulp, ultrasonic treatment time 60 seconds, processing power 700 watts, pulp concentration 1.0%, ultrasonic frequency 25KHz. The measurement results are shown in Table 1.

[0039] Table 1

[0040]

Embodiment 2

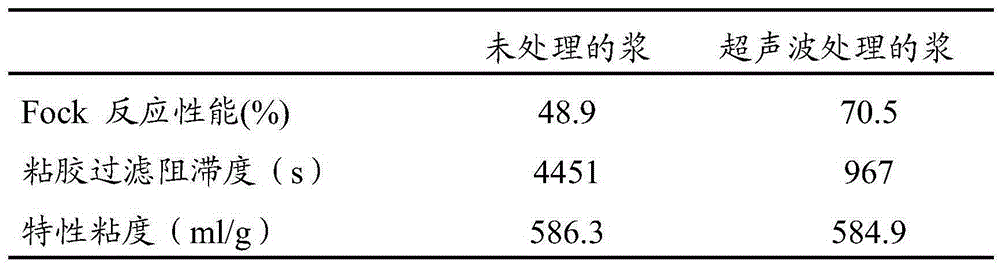

[0041] Example 2: poplar wood sulfite dissolving pulp, ultrasonic treatment time 90 seconds, processing power 560 watts, pulp concentration 0.5%, ultrasonic frequency 25KHz. The measurement results are shown in Table 2.

[0042] Table 2

[0043]

Embodiment 3

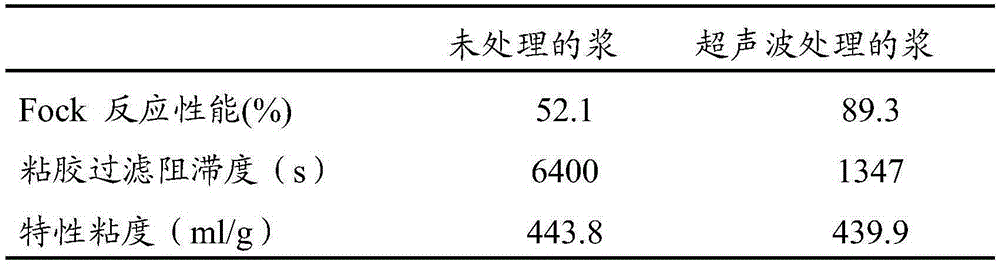

[0044]Example 3: Masson pine pre-hydrolyzed sulfate dissolving pulp, ultrasonic treatment time 300 seconds, processing power 630 watts, pulp concentration 1.5%, ultrasonic frequency 25KHz. The measurement results are shown in Table 3.

[0045] table 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com