Detachable rotatably-mounted filter and fluid filtering method thereof

A filter and filter element technology, which is applied in the installation/connection of lubricant purification devices, charging systems, machines/engines, etc., can solve the problems that spin-on filters are not economical and environmentally friendly, and achieve ingenious design and good guarantee. Working conditions, the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The detachable spin-on filter and its fluid filtering method of the present invention will be further described in detail below in conjunction with specific drawings.

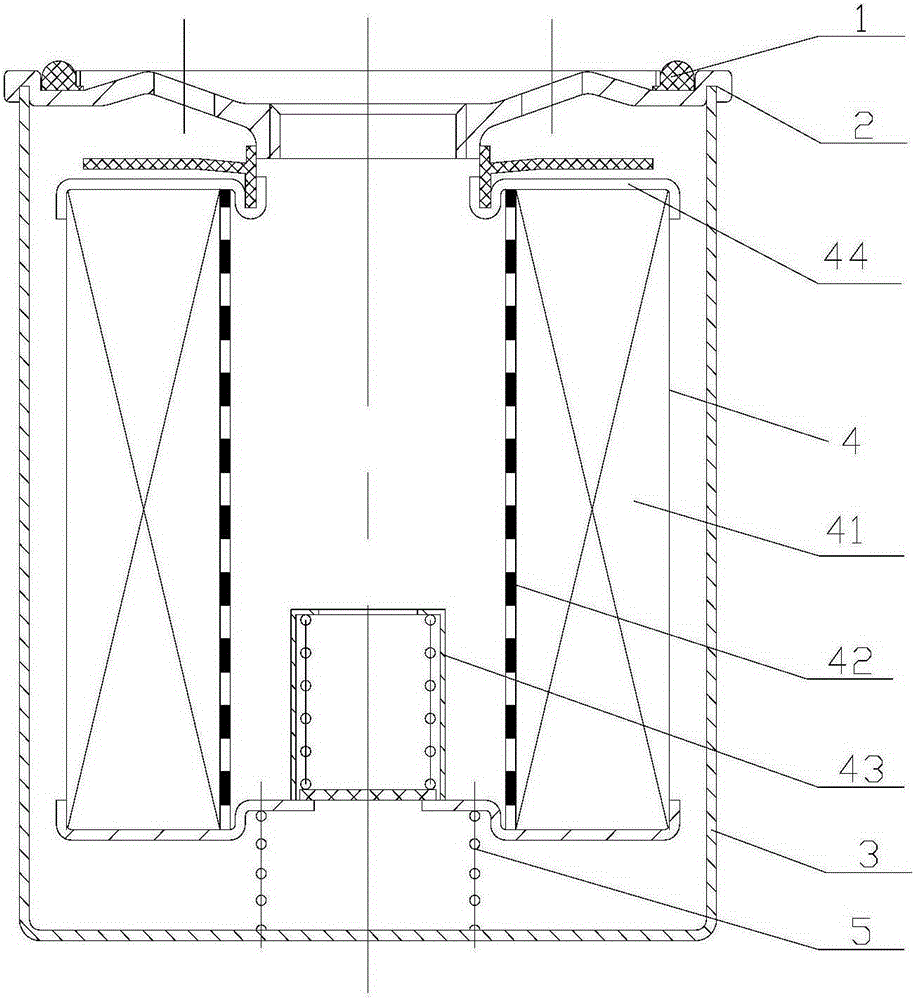

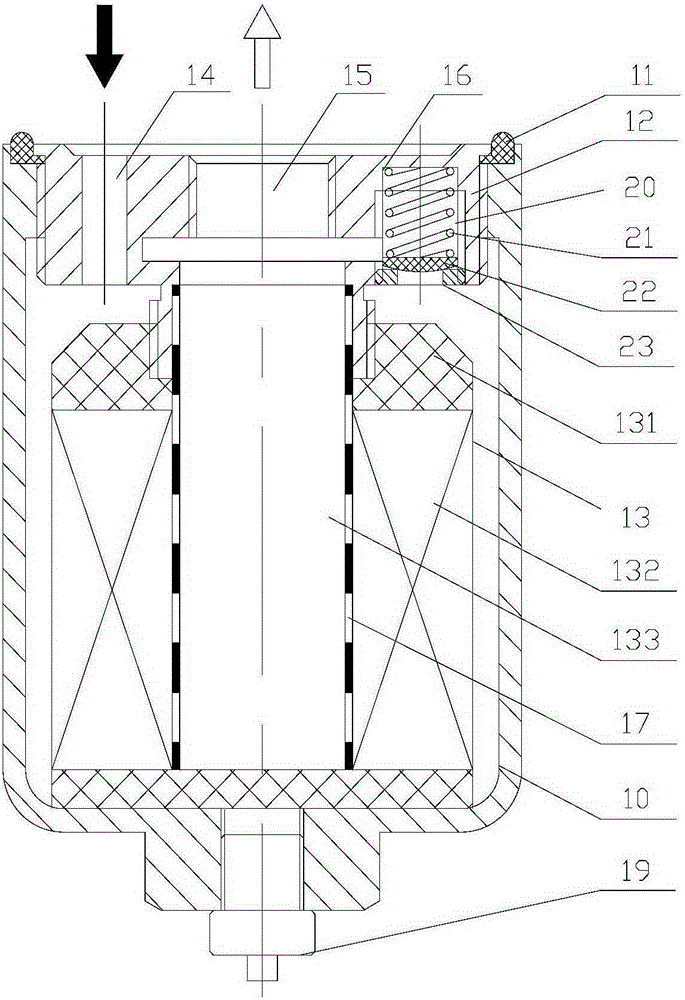

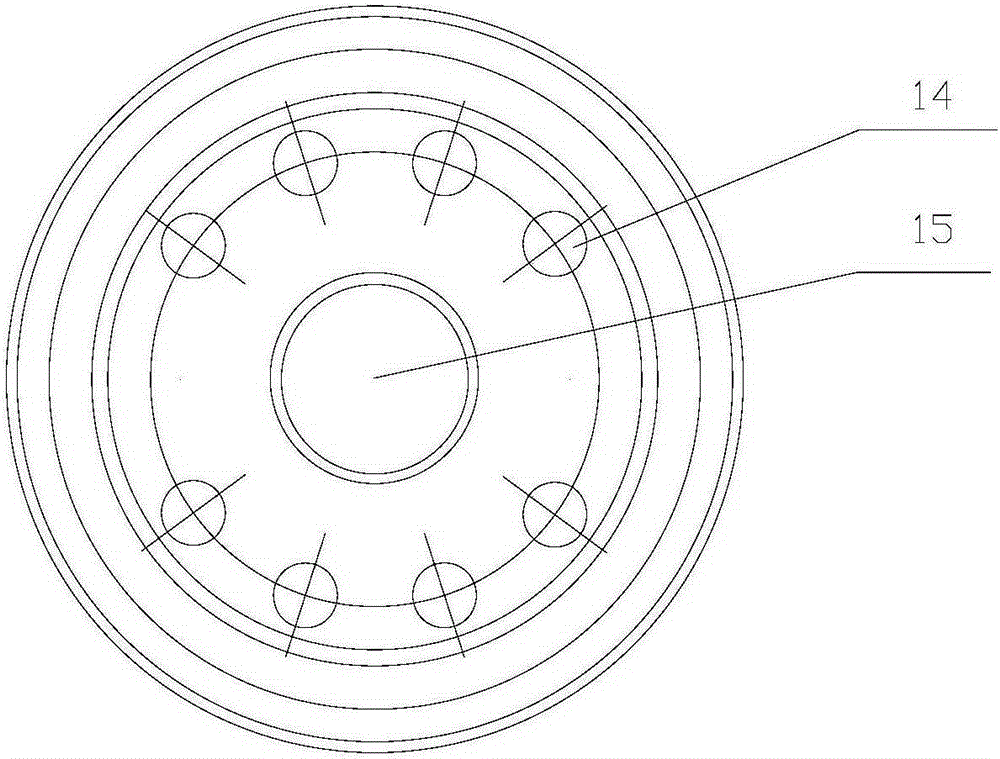

[0030] Such as figure 2 As shown, it is a detachable spin-on filter of the present invention, including a filter housing 10, a sealing gasket 11, a coupling head 12 and a filter element 13 located below the coupling head 12, and the sealing gasket 11 is pressed against the coupling head 12 and the coupling head 12. Between the filter housings 10, the coupling head 12 and the filter housing 10 are connected by threads, and the coupling head 12 is provided with several oil inlet holes 14 (such as image 3 As shown), the center is provided with a central hole 15, and each side of the central hole 15 is provided with a counterbore 16, and the two counterbore holes 16 are arranged symmetrically and communicate with the central hole 15, and the counterbore 16 is provided with a bypass Valve 20, the filter el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com