Variable-angle large-flow low-noise engine cooling fan

A cooling fan, variable angle technology, applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of small flow and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

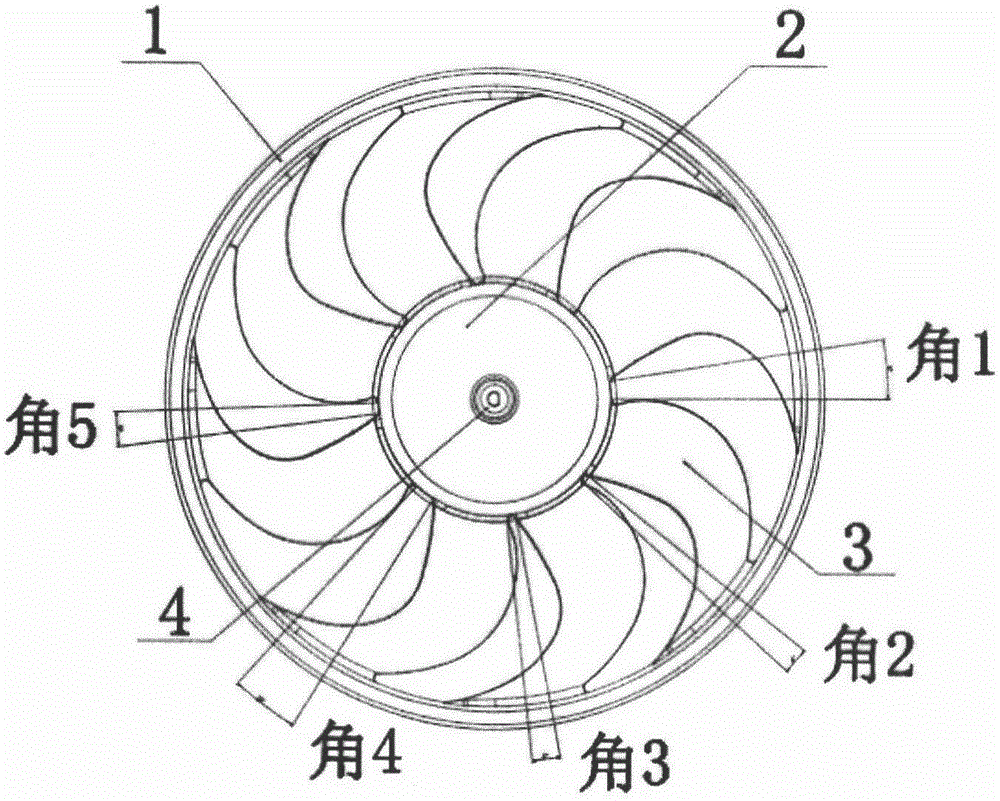

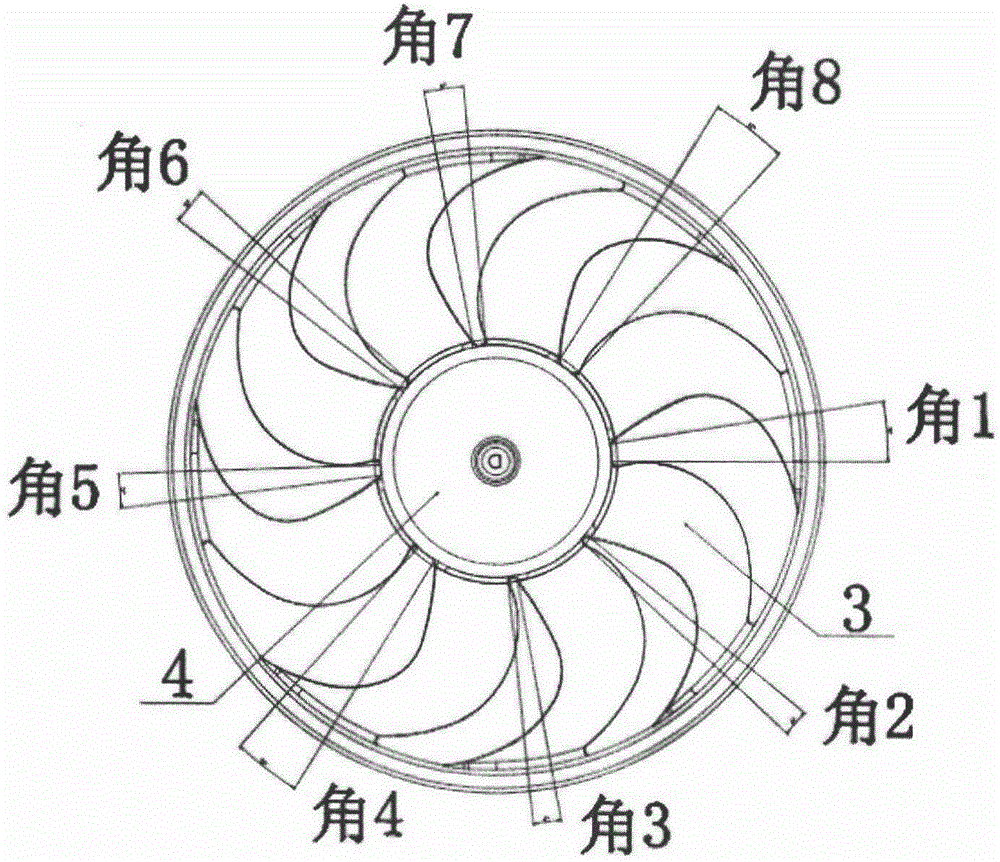

[0011] see figure 1 and Figure 4 As shown, the large-flow low-noise engine cooling fan includes a windshield (1), a cylindrical hub (2), fan blades (3), inserts (4) and radial ribs (5).

[0012] Among them, the cylindrical hub (2) cooperates with the drive shaft of the drive motor through the insert (4); a plurality of rotating fan blades (3) are radially arranged on the outer peripheral surface of the hub (2) and are aligned with the hub (2) They are connected at unequal angles; the outer ring of the radial fan (2) has a windshield ring (1) for improving rotation rigidity and reducing deformation.

[0013] see figure 1 and figure 2 As shown, the fan blades (3) and the hub (2) are connected at unequal angles to reduce the flow loss. The specific angle size is determined by the CFD flow field noise analysis, and the angle is corrected by the wind noise test .

[0014] see image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com