A Dynamic and Static Hybrid Tilting Pad Radial Gas Bearing

A gas bearing, dynamic and static pressure technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of friction and wear, uneven thermal expansion of bearing temperature distribution, etc., to achieve small temperature rise, avoid direct contact friction, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

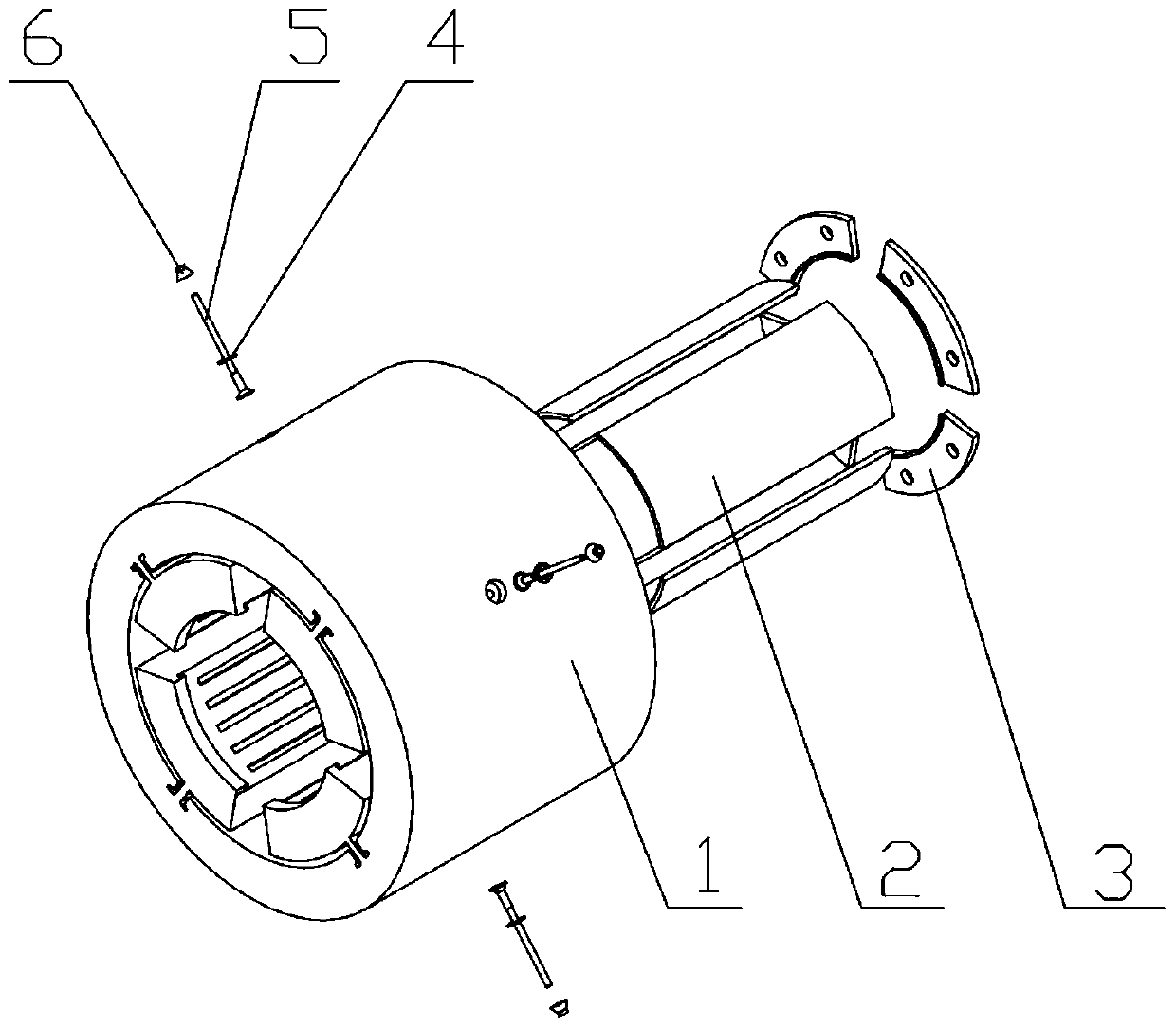

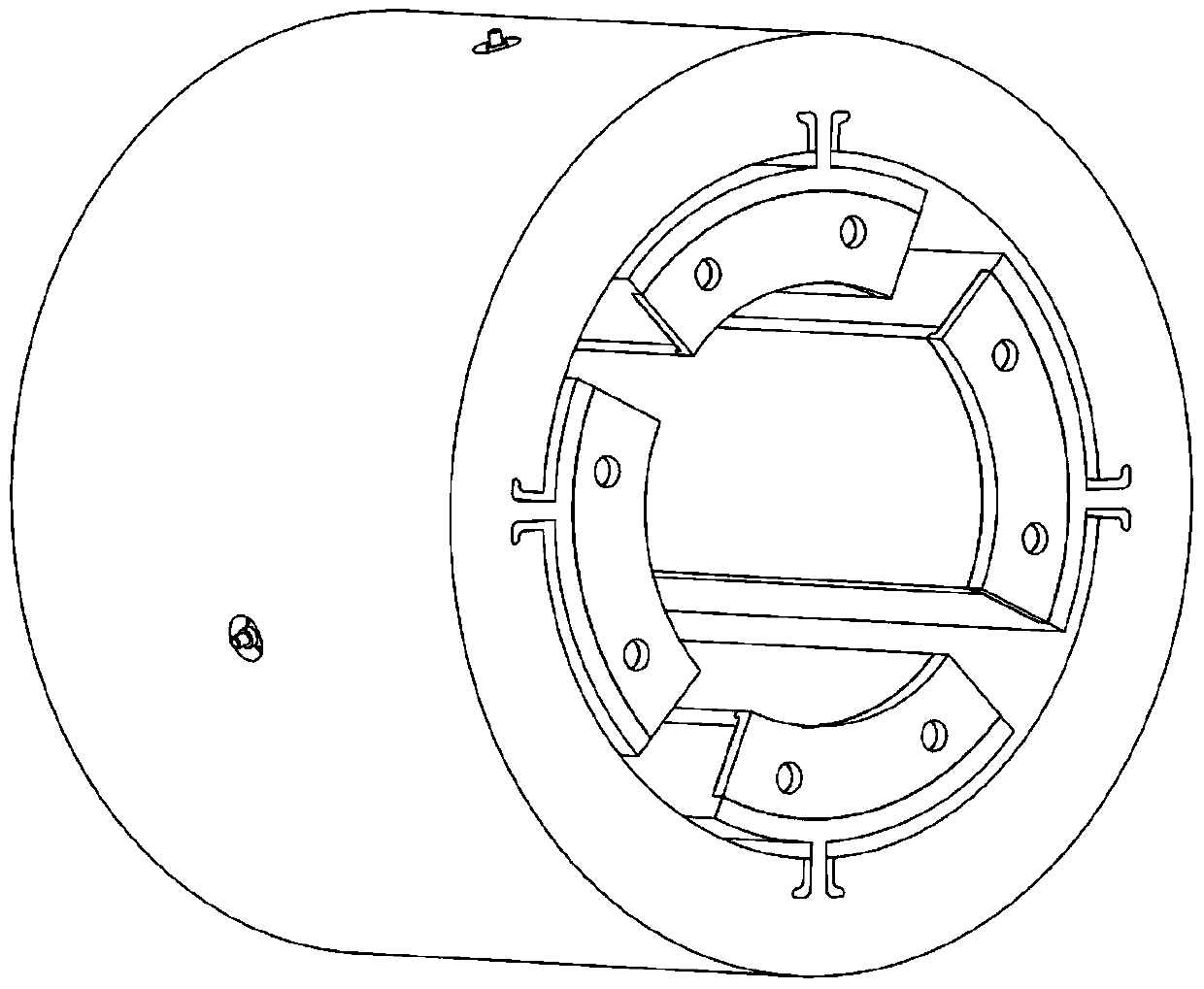

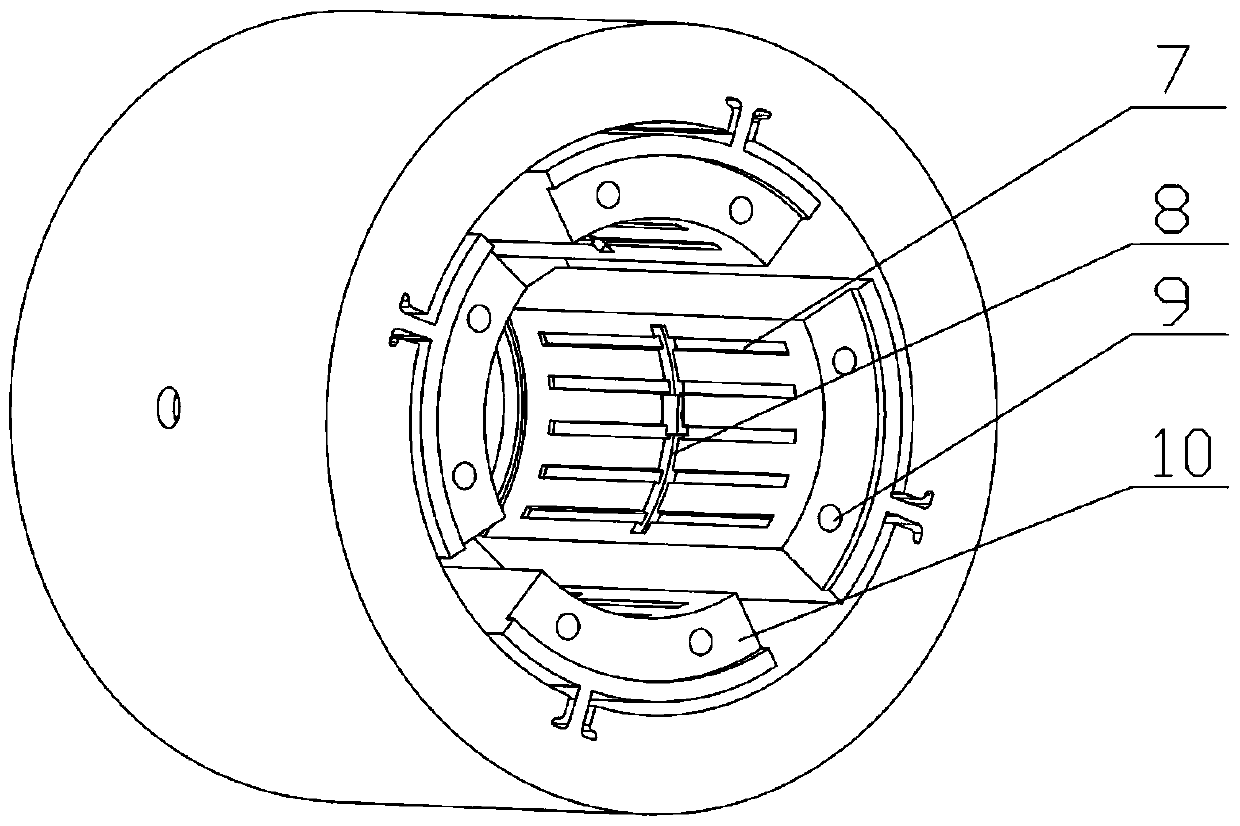

[0023] like figure 1 , figure 2 As shown, a dynamic and static pressure hybrid tilting pad radial gas bearing mainly consists of an integrated tilting pad radial gas bearing body 1, a porous tile surface 2, a porous tile surface clamping plate 3, and a compressible sealing ring 4 , an air intake pipe 5 and a conical cap 6, the porous tile surface 2 adopts a shoulder structure, and is embedded in the groove 14 of the tilting pad radial gas bearing body 1 to form a circumferential positioning and clamping, and pass through The coaxial adhesive is closely attached to the inner wall of the one-piece tilting pad radial gas bearing body 1, and is axially clamped through the flange 21 on the porous pad surface clamping plate to form axial positioning clamping. The integrated tilting pad radial gas beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com