Control structure for automatically changing samples in closed high-pressure reaction chamber and automatic sample changing method

A high-pressure reaction chamber, automatic sample changing technology, applied in the field of rock mechanics test, can solve the problem of lack of instruments, and achieve the effect of eliminating errors, easy operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

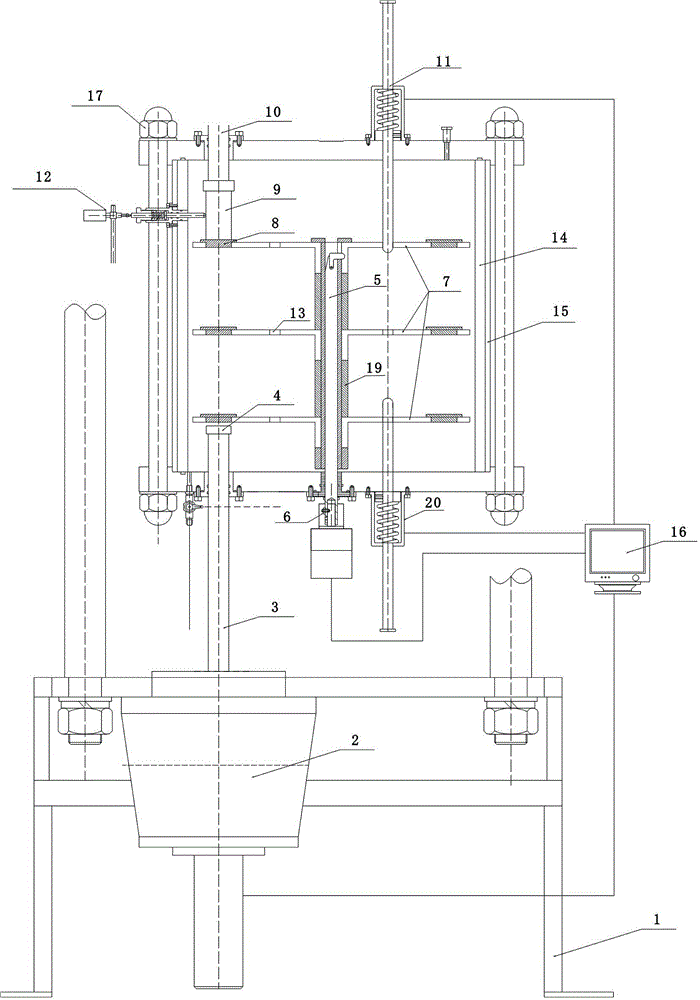

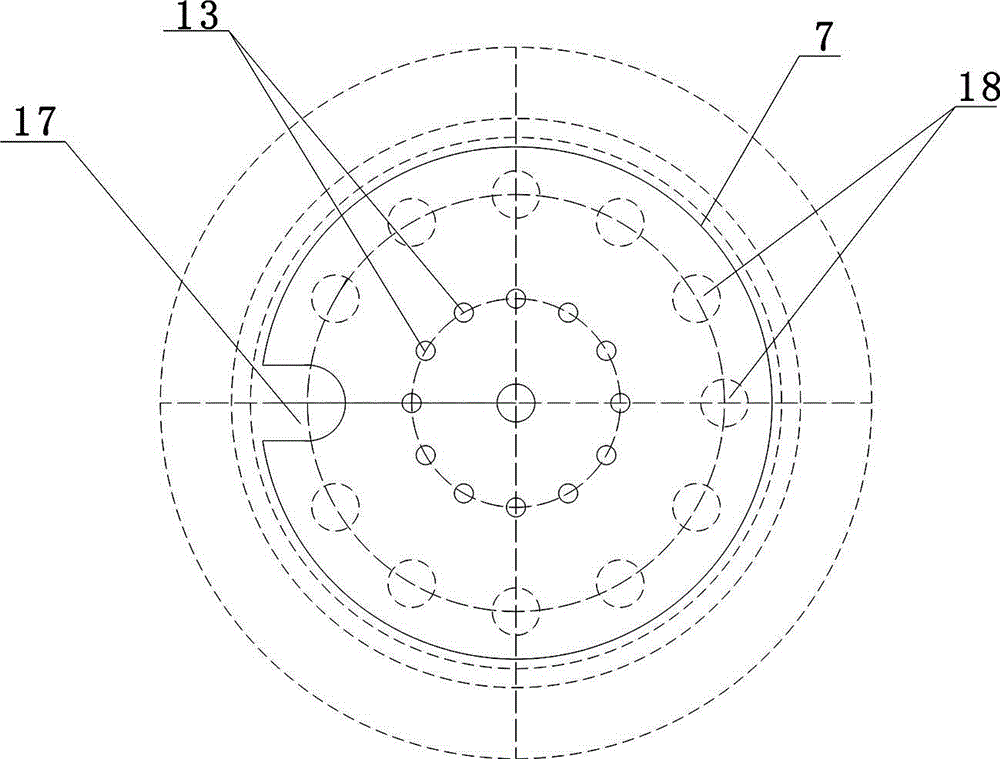

[0018] Such as figure 1 , figure 2 As shown, a control structure for automatic sample change in a closed high-pressure reaction chamber, including a worktable lifting mechanism, a retainer rotation mechanism, and a retainer positioning mechanism.

[0019] The workbench lifting mechanism includes a lifting rod 3, the top of the lifting rod 3 is provided with a support 4, and the lifting rod 3 is connected to a driving motor, and the driving motor is used to drive the lifting rod 3 to slowly rise and fall in the pressure chamber. The lifting rod 3 is made of high-strength and high-rigidity specific steel, the diameter of the lifting rod 3 is 50 mm, and the diameter of the support 4 is 60 mm.

[0020] The pressure chamber includes an outer layer: a stainless steel tube 15 with an outer diameter of 640 mm and a thickness of 10 mm; an inner layer: an organic glass tube 14 with an outer diameter of 640 mm and a thickness of 20 mm.

[0021] Lifting workbench 2 is installed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com