Quantitative characterization method of adhesive force of organic silicon resin transparent coating

A transparent coating and quantitative characterization technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of poor adhesion, low surface energy, adhesive and coating damage, etc., to avoid calibration and improve The effect of accuracy and data dispersion is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

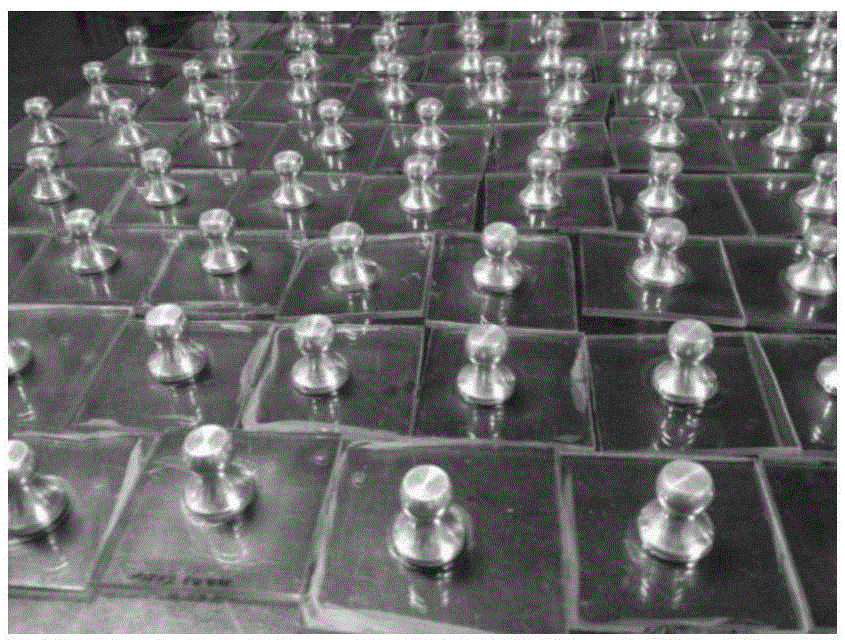

[0025] A method for quantitatively testing the adhesion of transparent coatings, suitable for the detection of coatings on optical plastic surfaces, comprising the following steps: coating commercial coatings on the surface of polycarbonate optical plastics by flow coating, and placing them in an oven Curing; connect the clean test column with the coating with an adhesive; after the adhesive is cured, steadily increase the tensile stress at a rate not exceeding 1MPa / s, preferably 0.2MPa / s, until the adhesion fails.

[0026] During the implementation process, the adhesives were silicone (Kraft fast glue), polyurethane (iron anchor 101 glue) and AB type epoxy resin (grade 914), and different types of adhesives were selected for the pull-off experiment. , observe the damaged surface, the damaged surface is the cohesion between the coating and the adhesive, the adhesive and the test column or the adhesive, denoted as NO, and the damaged surface is the cohesion between the coating a...

Embodiment 2

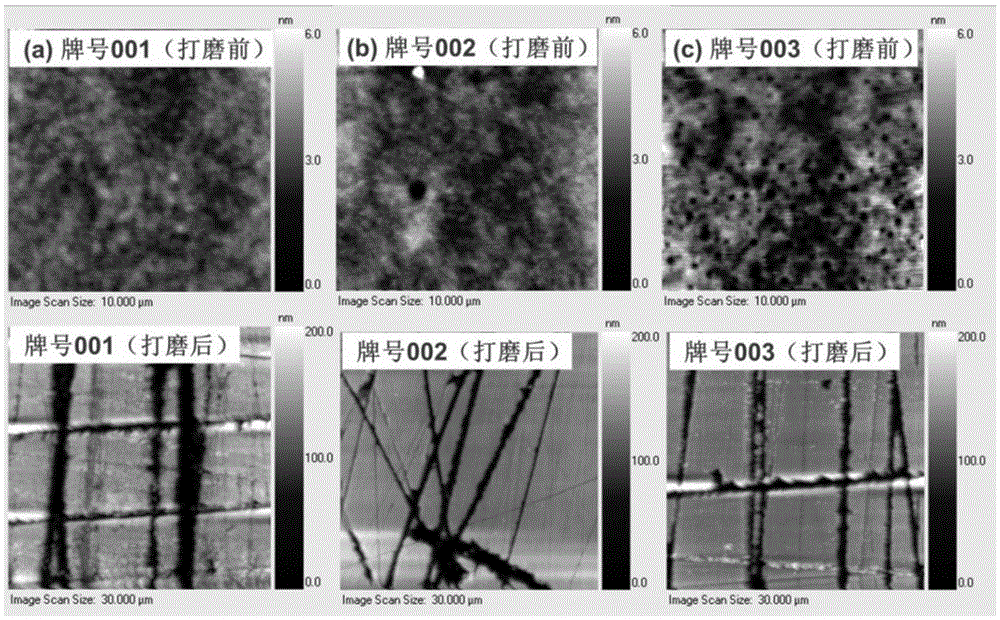

[0028] A method for quantitatively testing the adhesion of transparent coatings, suitable for the detection of coatings on optical plastic surfaces, comprising the following steps: coating commercial coatings on the surface of polycarbonate optical plastics by flow coating, and placing them in an oven Curing; after the coating is cured, use 5000 mesh sandpaper to polish the surface of the coating. After grinding, the surface roughness increases from 1nm to 40nm. The surface morphology before and after sandpaper grinding is shown in the topography scanning picture ( figure 2 shown). Use an adhesive to connect the test column to the clean coating; after the adhesive is cured, increase the tensile stress steadily at a rate of 0.2-1MPa / s until the adhesion fails.

[0029] During the implementation process, the adhesive used was 914 epoxy glue, and the coating used was a commercial silicone (coating number 001, 002, 003, 004) and polyurethane (coating number 005) transparent coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com