Optical Kerr effect-based beam radially smoothing method in inertial confinement fusion device

A technology of inertial confinement fusion and light beams, applied in optics, optical components, instruments, etc., can solve problems such as difficult adjustment and complex optical path structure, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

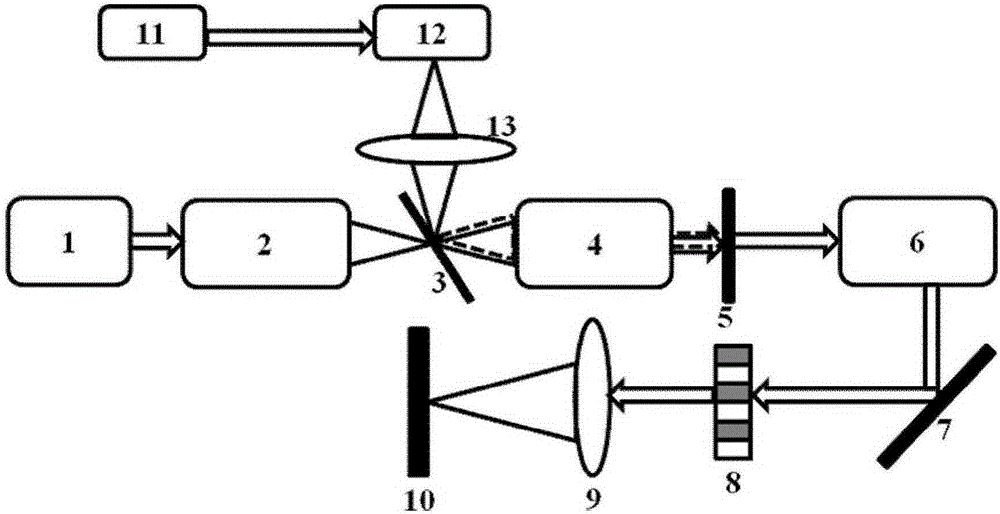

Method used

Image

Examples

Embodiment 1

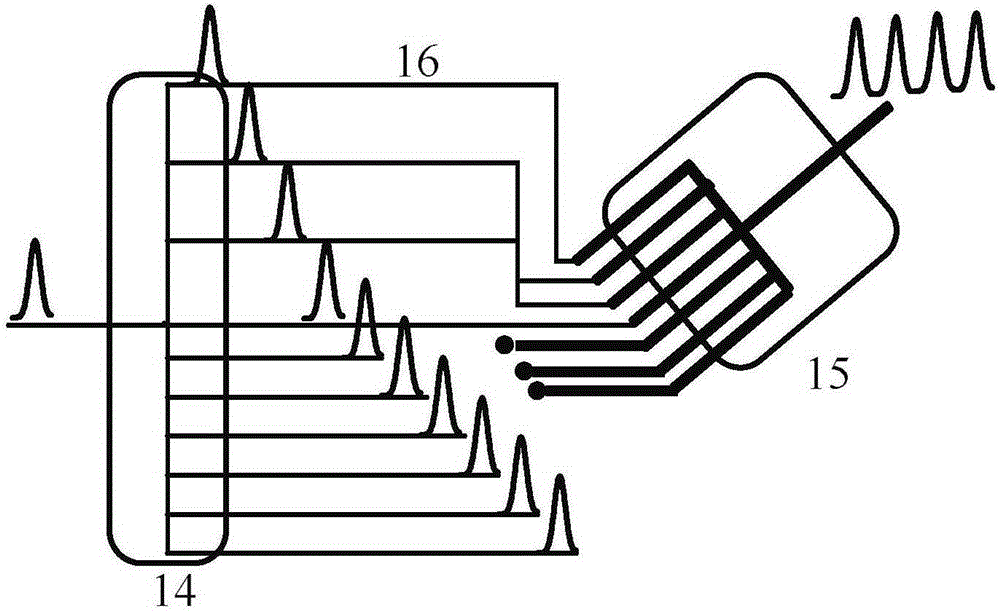

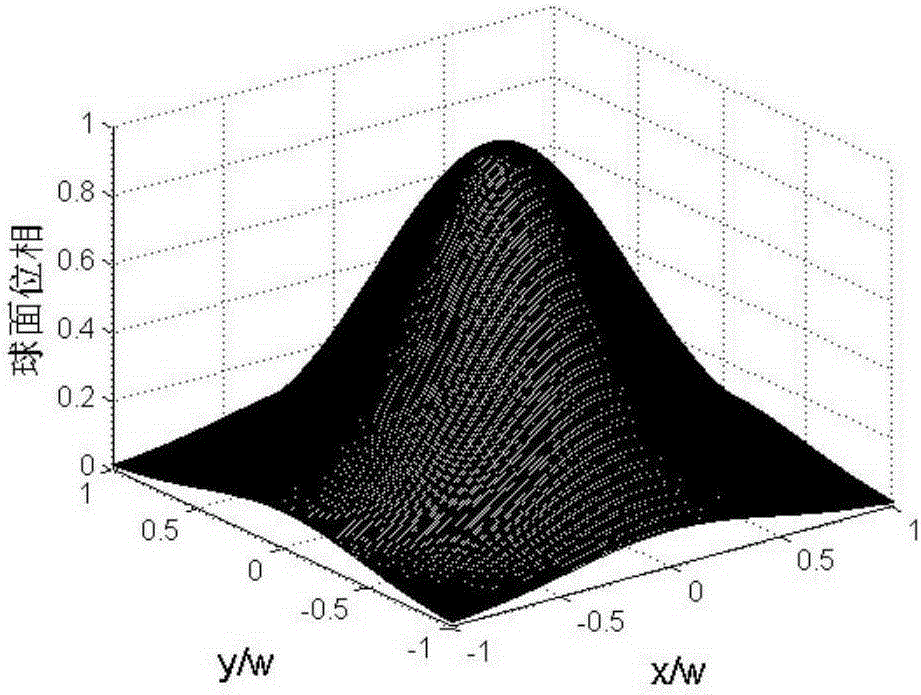

[0053] The optical Kerr medium used in this embodiment is graphene, because of its characteristics such as high optical Kerr coefficient, high damage threshold and large light aperture, the parameters of graphene are: optical Kerr coefficient n 2 =6×10 -8 cm 2 / W, thickness d=0.5nm, size 40×40mm; Gaussian pulse wavelength λ=808nm output by the tunable picosecond laser 11, and the pulse width of full width at half maximum is T w =2.2ps, pulse peak intensity I p =0.2GW / cm 2 , the time delay factor h=3.3 between multiple optical fibers in the fiber pulse stacking unit 12, and the integration time Δt=10ps; the picosecond laser 11 is a tunable picosecond laser; the filter element is an optical rotator.

[0054] The specific operation steps are as follows:

[0055] (1) First, in the optical transmission chain of the laser-driven inertial confinement fusion device, a radial beam smoothing device is added, and the output light wavelength is selected as a tunable picosecond laser 1...

Embodiment 2

[0083] The optical Kerr medium 4 used in this embodiment is carbon disulfide (CS 2 ), its parameter is: optical Kerr coefficient n 2 =2.1×10 -15 cm 2 / W, thickness d=0.45mm, size 40×40mm; the Gaussian pulse wavelength output by the tunable picosecond laser 11 is λ=800nm, and the pulse width T of full width at half maximum w =2.2ps, pulse peak intensity I p =63.5GW / cm 2 , the time delay factor of the fiber pulse accumulation unit 12 is h=3.3, and the integration time Δt=10 ps; the filter element is a filter. The other operation steps and operation process are the same as those in Embodiment 1, and the same effect of improving the uniformity of the far-field focal spot of the laser beam as in Embodiment 1 can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com