Uncertain design method for thin plate tension variable blank holder force based on sequential approximate optimization

A technology of sequence approximation and variable blank-holding force, which is applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of uncertain optimization design of thin plate stretching variable blank-holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

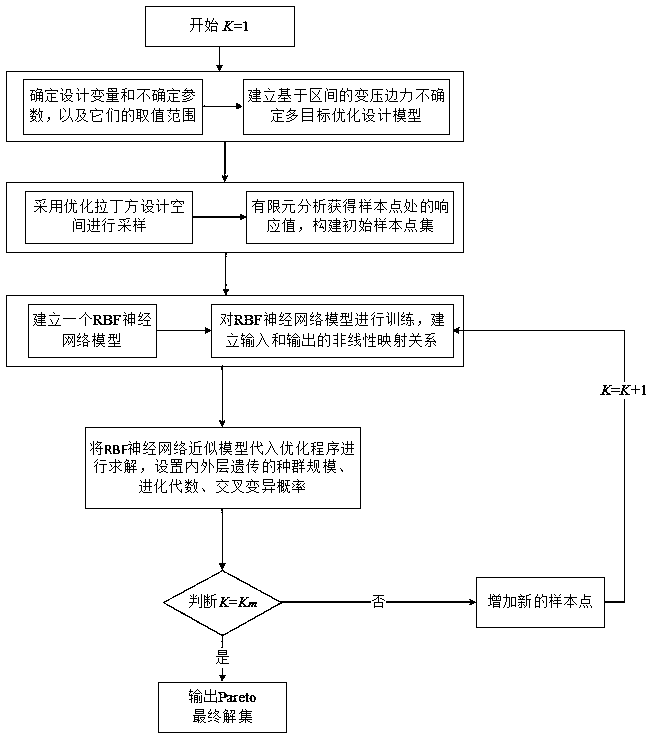

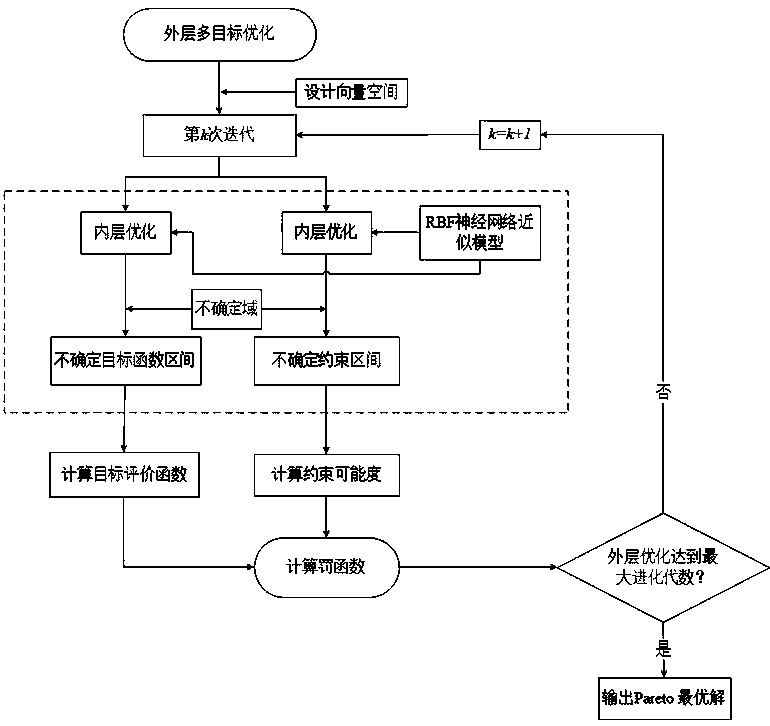

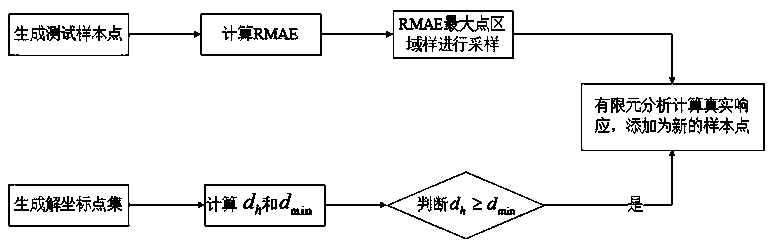

[0070] The present invention is further described below in conjunction with embodiment and accompanying drawing. The overall steps are as figure 1 shown.

[0071] 1) Set the maximum iteration number Km of sequential approximate optimization to 5, and the current iteration number K to 1.

[0072] 2) Establish a multi-objective optimization design model with variable blank holder force uncertainty.

[0073] The sheet material and mold layout of a certain type of large-size thin-walled component are as follows figure 2 As shown, the thin-walled member is a semi-ellipsoid with a major semi-axis length of 900 mm and a minor semi-axis length of 750 mm, with a wall thickness of 3 mm and made of aluminum alloy. The semi-major axis of the punch is a=900mm, the semi-minor axis b=750mm, the semi-major axis of the die is c=903mm, and the semi-minor axis d=753mm. Since the model is an axisymmetric model, the following image 3 The quarter model shown was subjected to finite element a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com