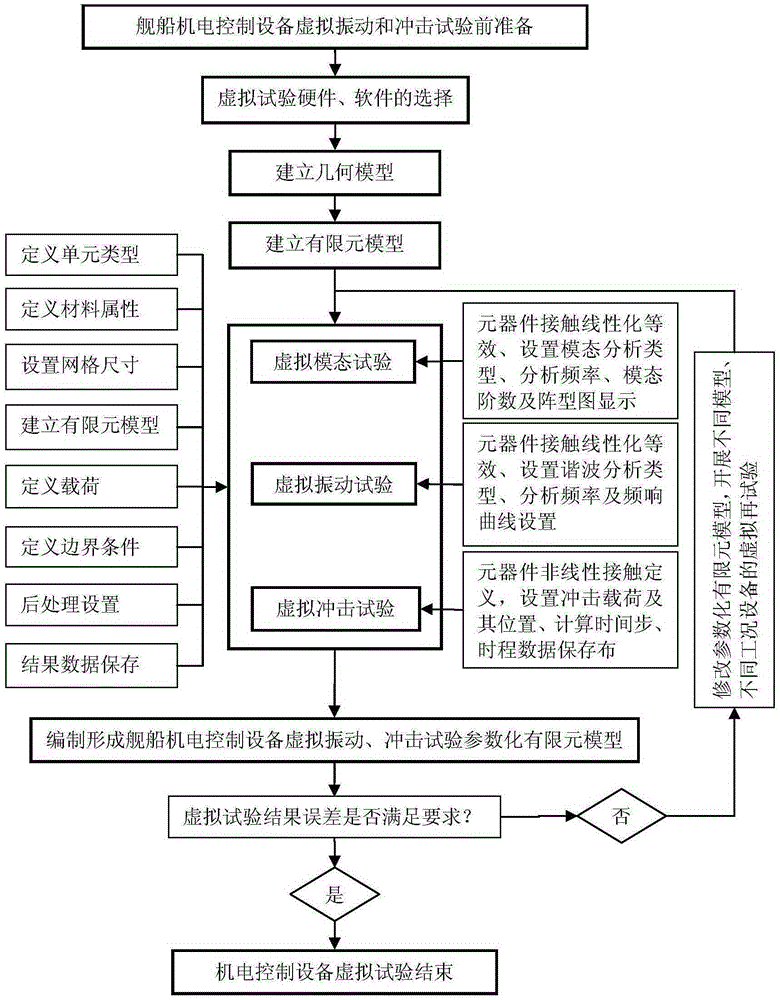

Method for virtual vibration and impact tests of electromechanical control equipment of ship

An electromechanical control and impact test technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that limit the dynamic performance analysis calculation efficiency and application range of virtual test technology products, shorten the development cycle, improve The level of design and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] The specific implementation is as follows:

[0032] In terms of the establishment of the geometric model, according to the structural form of the ship’s electromechanical control equipment, the equipment structure is simplified to facilitate the finite element mesh division and dynamic calculation, that is, to simplify the components, elements or Connection forms, such as deleting small chamfers, fillets, and repairing damaged structures. Use parametric design language to generate point, line, surface and body features of electromechanical control equipment, and perform corresponding feature processing such as addition, subtraction, merging and bonding, as well as geometric model processing such as movement, copying, rotation and mirroring, until the generation Parametric geometric models of electromechanical control devices. In addition, there are some electronic components with very complex structures inside the electric control box, but their weight and size are not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com