Multi-terminal lead storage battery recycling apparatus and method

A regeneration device, lead battery technology, applied in secondary batteries, secondary battery testing, electrochemical generators, etc., to achieve significant effects of improving regeneration level, reducing environmental pollution, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

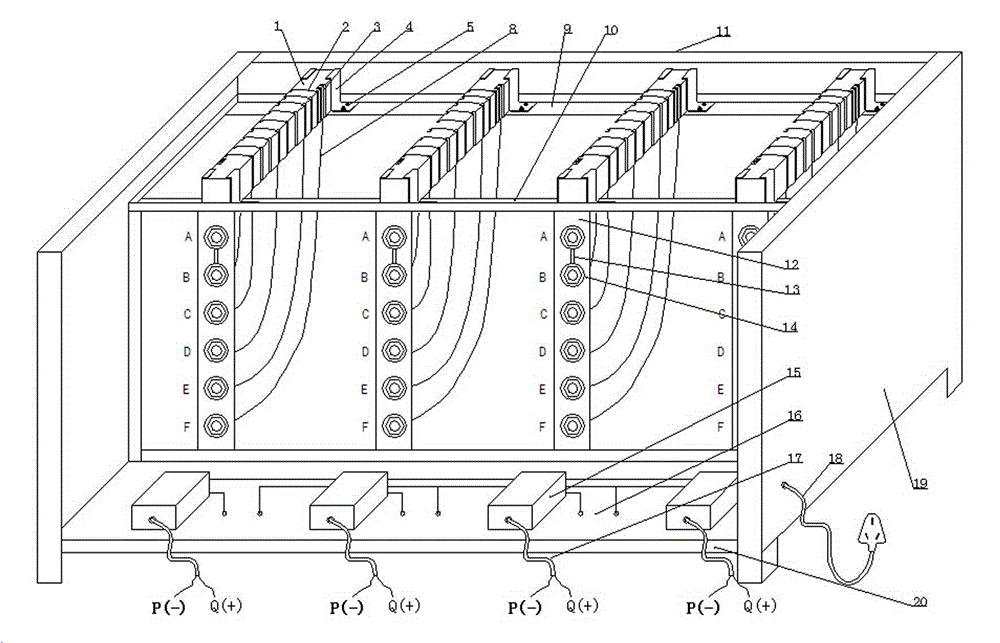

[0072] The reverse constant current pulse charger 15 of the present invention is a 48V lead battery charger, which can process 48V lead batteries of 4 electric vehicles at one time, and the specific operation steps are as follows:

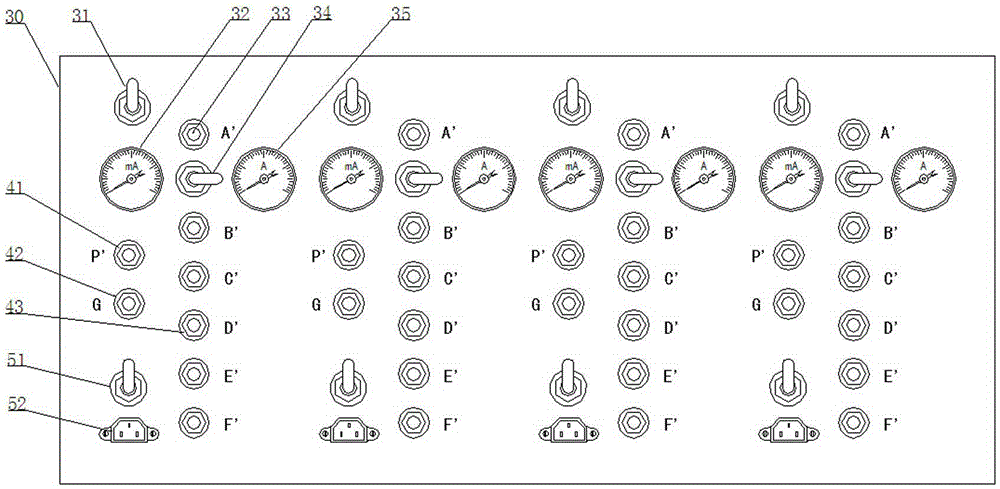

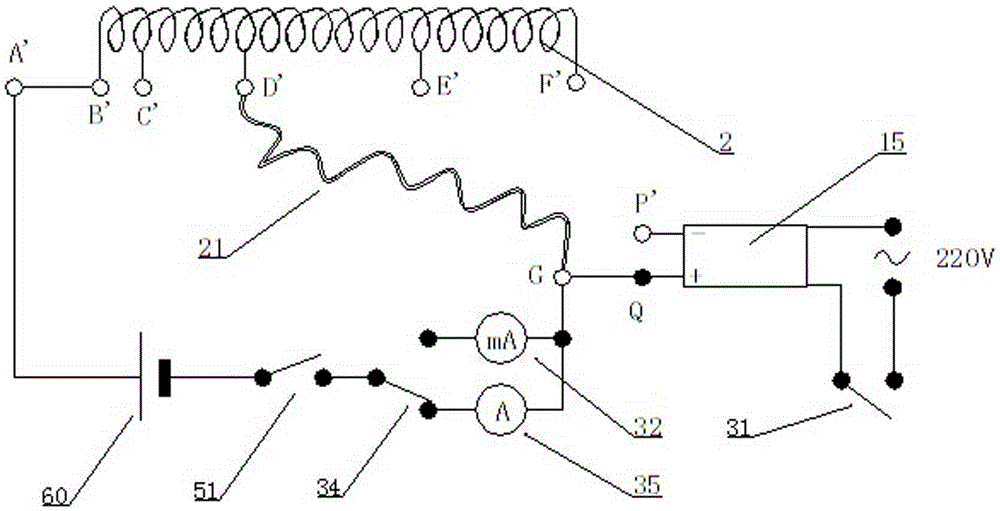

[0073] Step 1. Use a double-plug cable 21. The cross-sectional area is configured according to the Ah value of the lead battery. In this embodiment, it is 2.5mm2. Connect one end M of it to the jack G ( figure 2 , 42), the other end N is connected to the socket F’ ( figure 2 ,33-F');

[0074] Step two, such as figure 2 , the total circuit control switch 51 and the reverse constant current pulse charger 31 should be in the state of "off", and the selector switch 34 of the milliampere meter 32 and the ammeter 35 is turned to the ammeter 35 and connected;

[0075] Step 3, turn on the total circuit control switch 51, so that the lead battery is discharged through the resistance wire, and the ammeter displays the current reading, for example, 6A; ...

Embodiment 2

[0085] In this embodiment, its reverse constant current pulse chargers 15 are all 36V lead battery chargers, which can process 36V lead batteries of 4 electric vehicles at one time, and the specific operation method is the same as that of embodiment 1.

Embodiment 3

[0087] In this embodiment, its reverse constant current pulse chargers 15 are all 60V lead battery chargers, which can process the 60V lead batteries of 4 electric vehicles at one time, and the specific operation method is the same as that of embodiment 1.

[0088] The present invention has been described with four processing units in parallel. In fact, according to the principle of the present invention, several units and lead battery processing devices with different nominal voltages can be designed in parallel. Therefore, if only the number of units or the output voltage of the reverse constant current pulse charger 15 is changed, all should belong to the coverage of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com