Garlic polysaccharide microcapsules as well as preparation method and application thereof

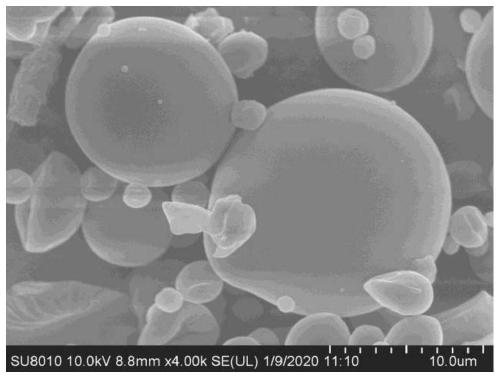

A technology of garlic polysaccharides and microcapsules, which is applied in microcapsules, applications, capsule delivery, etc., can solve the problems of complicated chelation process, complicated embedding process, and low safety, and achieve good instant solubility and stability, and prolong activity Effective period, the effect of increasing corporate income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

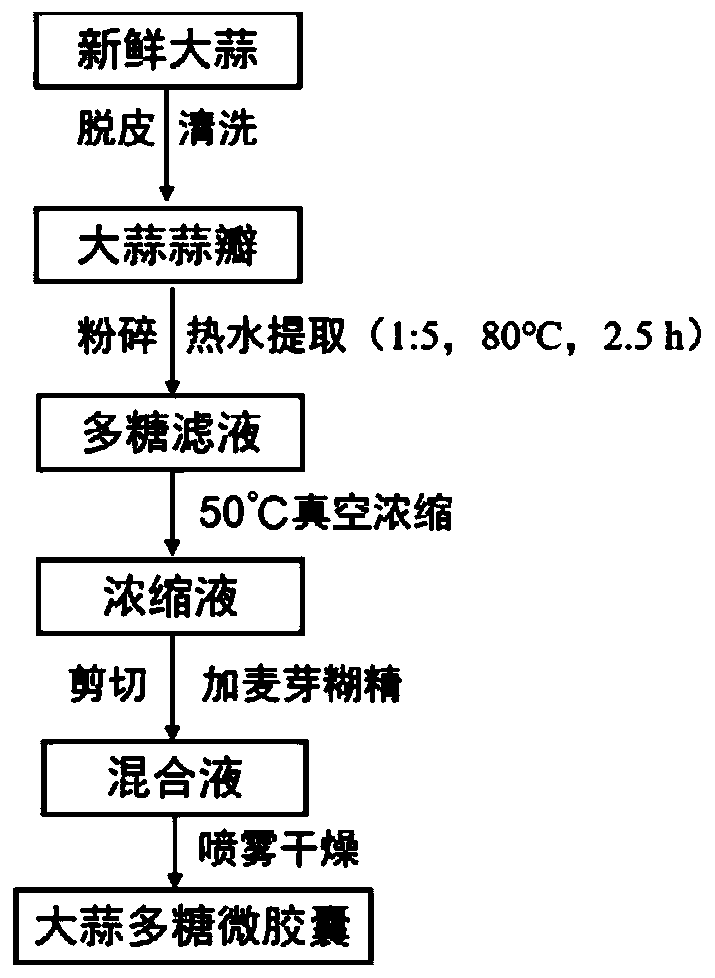

[0034] Embodiment 1, the preparation of garlic polysaccharide microcapsules

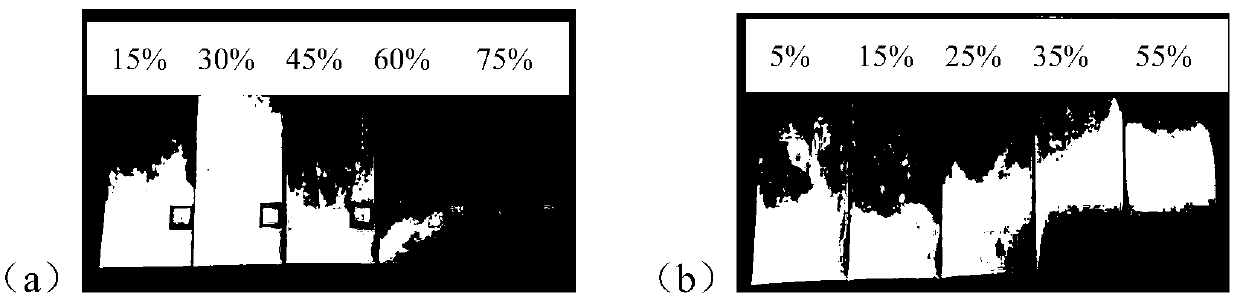

[0035] Exploratory experiment of the polysaccharide concentration in the feed liquid on the preparation process of garlic polysaccharide microcapsules:

[0036] a: Select clean and peeled 150g fresh garlic, grind it with a mincer, add different volumes of distilled water (the mass ratio of garlic to water is 10% to 50%), prepare polysaccharide extract, and put it in a water bath at 80°C Extract at constant temperature for 2.5 hours, filter out the filter residue with 300-mesh nylon cloth, and obtain crude extract by suction filtration;

[0037] b: The extract is centrifuged at 8000rpm for 10min, the precipitate is discarded first, and then the supernatant is concentrated in vacuum at 50°C, so that the concentration of the concentrated polysaccharide extract reaches 15% to 75% (calculated as the concentration of the feed solution , as shown in Table 1); and collect the concentrate;

[0038] c: When ...

Embodiment 2

[0046] Embodiment 2, preparation of garlic polysaccharide microcapsules

[0047] Exploratory experiment on the effect of wall material addition on microencapsulation process:

[0048] a: Choose clean and peeled 150g fresh garlic, grind it with a mincer, add 1.5L distilled water to prepare polysaccharide extract, extract in a water bath at 80°C for 2.5h at a constant temperature, filter out the filter residue with 300-mesh nylon cloth, and filter with suction Obtain crude extract;

[0049] b: Centrifuge the extract at 8000rpm for 10min, discard the precipitate first, then concentrate the supernatant in vacuum at 50°C, so that the concentration of the concentrated polysaccharide extract reaches 30%; and collect the concentrate;

[0050] c: When mixing the wall material and the concentrate, use shear mixing to ensure uniform mixing. The shearing conditions include: the shear speed is 8000r / min, and the time is controlled within 4 minutes; the amount of wall material added is 10%...

Embodiment 3

[0058] Embodiment 3, preparation of garlic polysaccharide microcapsules

[0059] Influence experiment of air inlet temperature on powder output of microcapsules:

[0060] a: Choose clean and peeled 150g fresh garlic, grind it with a mincer, add 1.5L distilled water to prepare polysaccharide extract, extract in a water bath at 80°C for 2.5h at a constant temperature, filter out the filter residue with 300-mesh nylon cloth, and filter with suction Obtain crude extract;

[0061] b: Centrifuge the extract at 8000rpm for 10min, discard the precipitate first, then concentrate the supernatant in vacuum at 50°C, so that the concentration of the concentrated polysaccharide extract reaches 30%; and collect the concentrate;

[0062] c: When mixing the wall material with the concentrate, use shear mixing to ensure uniform mixing. The shearing conditions include: the shear speed is 8000r / min, and the time is controlled within 4 minutes; the amount of wall material added is 25%;

[0063] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com