Method for preparing positive electrode active material for lithium secondary battery

A positive electrode active material and lithium secondary battery technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve problems such as side reactions, promote electrolytes, and reduce the safety of secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

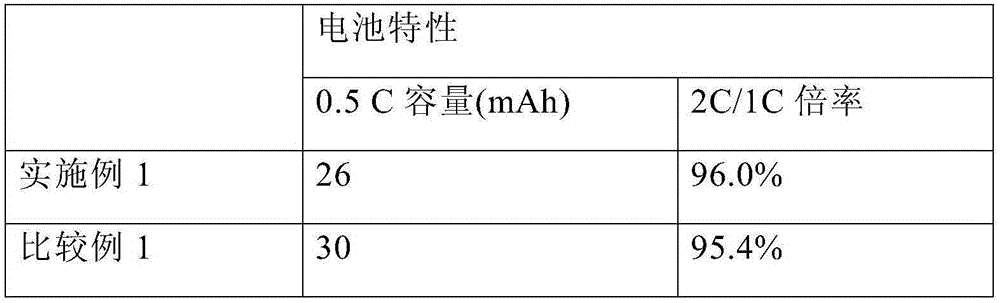

Examples

Embodiment 1

[0055] Preparation of positive electrode

[0056] Will Li(Li 1.2 co 0.1 Ni 0.1 mn 0.6 )O 2 Used as positive electrode active material, will contain 2.0g of BF dissolved in it 4100ml of the solution was added to the positive active material and mixed. The mixed solution was heat-treated at 250° C. and then delithiated by washing with water and vacuum drying. Subsequently, a surface modification process was performed using mechanical milling, thereby preparing a cathode active material.

[0057] The prepared positive electrode active material, carbon black as a conductive material, and PVdF as a binder were added to N-methyl-2-pyrrolidone (NMP) in a weight ratio of 90:5:5, and mixed, thereby preparing a positive electrode mixture. On an aluminum foil having a thickness of 20 μm as a cathode current collector, the prepared cathode mixture was coated to a thickness of 40 μm, followed by pressing and drying. As a result, a positive electrode was prepared.

[0058] Prep...

Embodiment 2

[0064] A lithium secondary battery was fabricated in the same manner as in Example 1 except that heat treatment was performed at 300° C. during delithiation of the cathode active material.

Embodiment 3

[0066] A lithium secondary battery was fabricated in the same manner as in Example 1 except that heat treatment was performed at 400° C. during delithiation of the cathode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com