Electric coagulation forceps system having cleaning function

An electrocoagulation tweezers system and functional technology, applied in the field of electrocoagulation tweezers, can solve the problems of unsealed waste, low efficiency, environmental pollution, etc., and achieve the effects of convenient lighting, convenient use and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

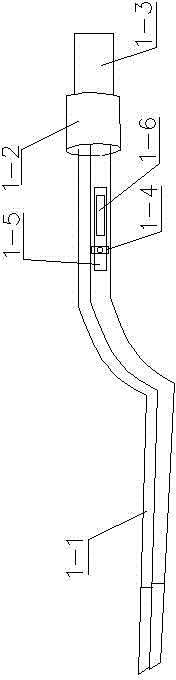

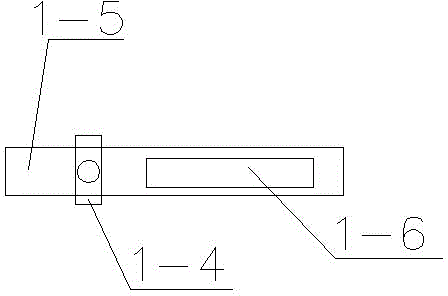

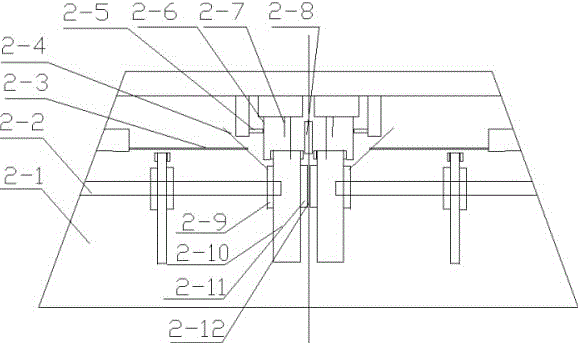

[0024] Embodiment 1: as figure 1 and figure 2 Said, a kind of electrocoagulation tweezers system with cleaning function, comprises tweezers bar 1-1 and electrode seat 1-2, and electrode seat 1-2 rear end has plug joint 1-3, and the inner side of two tweezers bars is provided with Drip tube, the outlet of the drip tube faces the direction of the tweezers tip of the tweezers. There is a position emitting chip in the tweezers on one side, and a position sensing chip in the tweezers on the other side. When the controller detects that the two tweezers are When approaching and then moving away, and after moving away, after the two tweezers do not approach again within the specified time, the controller controls the dripping pipe to quickly discharge clean water once to impact and clean the tweezers. A water diversion groove is also set inside the tweezers , the water guide groove is used to guide the clean water discharged from the outlet of the drip tube, so that the water flow w...

Embodiment 2

[0031] Embodiment 2: as Figure 6As shown, the difference from Embodiment 1 is that the bottom end of the hydraulic rod 6 of the third hydraulic rod has a horizontal part and a part extending obliquely upwards, forming a fishhook shape, and such a structure can better fold the upper part of the storage bag partly extended.

Embodiment 3

[0032] Embodiment 3: Different from Embodiment 1, a cleaning tape is also provided on the inner wall of the opening of the containing bag for wiping the tweezers rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com