Curtain bead automatic production device

A production device, curtain beading technology, which is applied in the field of automatic beading production equipment, can solve the problems of artificial influence, low efficiency, and mistakes in the length of cutting, and achieve the effect of accurate precision and fast efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

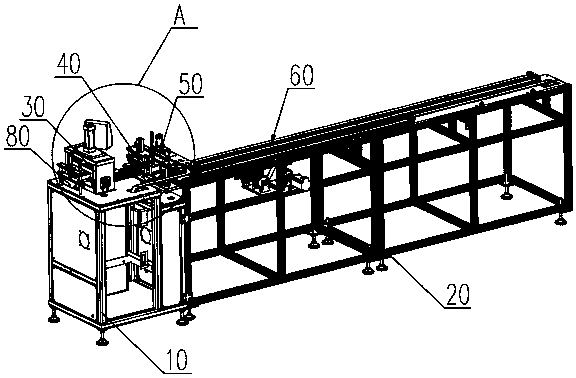

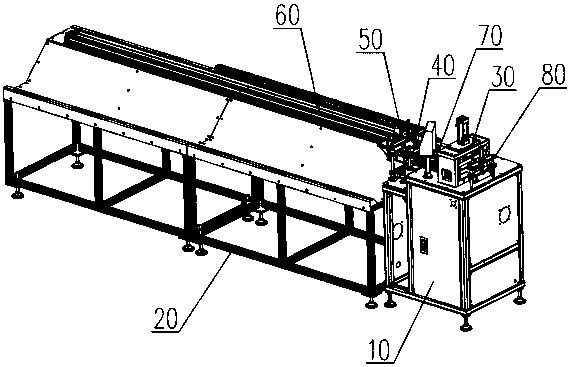

[0024] The present invention is an automatic production device for curtain beads, such as Figures 1 to 6 As shown, it includes a frame 10 and a workbench 20, and a chain-entry device 30 for introducing a pull-bead chain on the frame 10, and a chain-cutting device 40 for cutting a pull-bead chain. The zipper device 50 on the workbench 20 for clamping the bead chain and the measuring device 60 fixed with the zipper device 50 for measuring the length of the bead chain; also includes a circuit control device.

[0025] During use, first pull out the rolled bead chain, then manually hammer off the first three beads at one end of the bead chain, and then send the end of the bead chain into the chain-feeding device 30 After the pull-bead chain enters the chain-entry device 30, the chain-entry device 30 is introduced into the clip chain device 50 again, and the end of the pull-bead chain is clamped and fixed, and the measuring device fixed with the clip chain device 50 60 stretches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com