Electric vehicle mid-mounted battery box quick unloading and loading system

A technology for electric vehicles and battery boxes, which is applied to electric power units, power units, vehicle components, etc., can solve the problems of concentrated force points and deformation of battery boxes, and achieve the effects of reliable equipment operation, high exchange efficiency and rapid replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

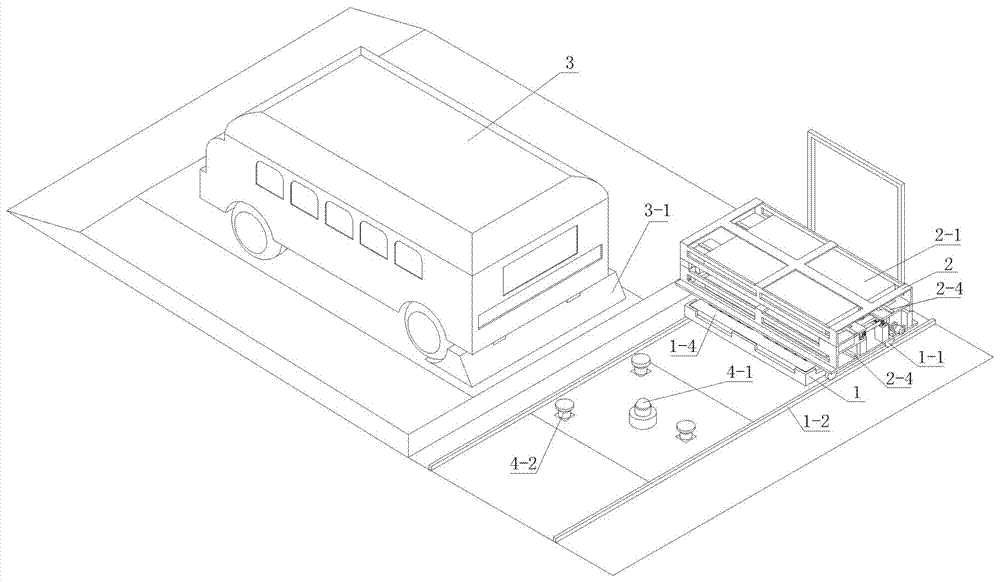

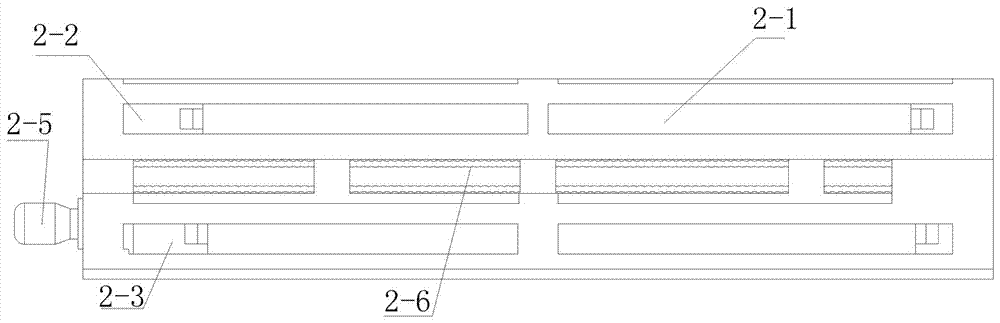

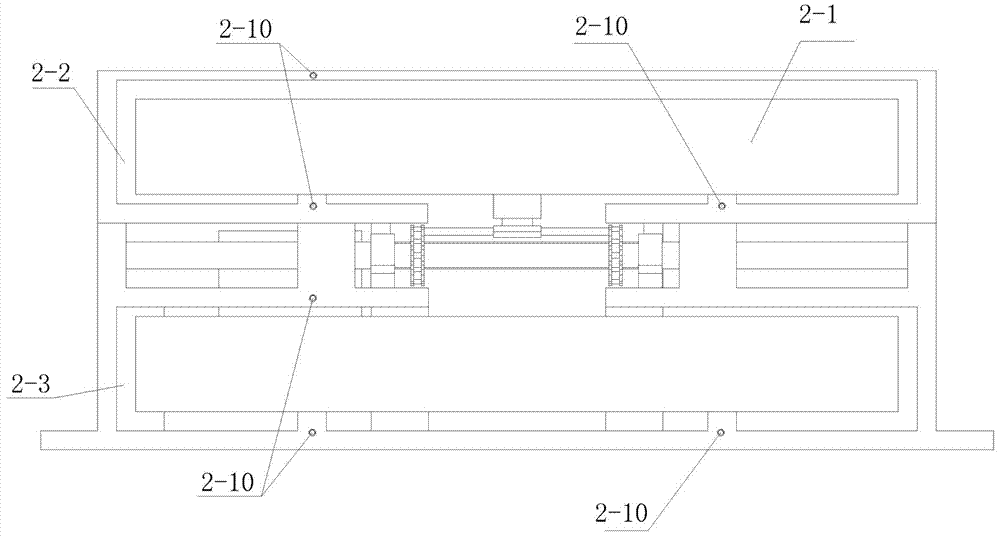

[0032] Electric vehicle center-mounted battery box quick unloading and loading system, the system includes a vehicle limiting platform, a transfer trolley 1 matched with the vehicle limiting platform and battery box charging cabinet, and a turnover frame 2 and a middle frame set on the transfer trolley 1 The key to the battery box 2-1 and supporting drive structure is:

[0033] 1) The limiting platform is provided with a locking device for the bottom plate of the electric vehicle 3,

[0034] 2) There is a rough adjustment device for plane docking of storage and transportation guide rails at the battery replacement station and the battery box transfer track.

[0035] 3) The front end of the turnover frame 2 of the battery box is equipped with a storage and transportation guide rail self-calibration docking combination mechanism, and with the help of the prompt of the control circuit and the cooperation of the docking guide parts installed on the electric vehicle, a fine adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com