A device for automatic upper and lower tubes for matching glass heat collecting tube tailing machine equipment

A glass heat collecting tube and tail-drawing machine technology, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems that multiple sets cannot be realized on a large scale, so as to facilitate detection and positioning, eliminate damage, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

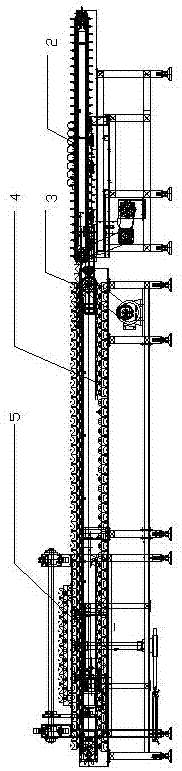

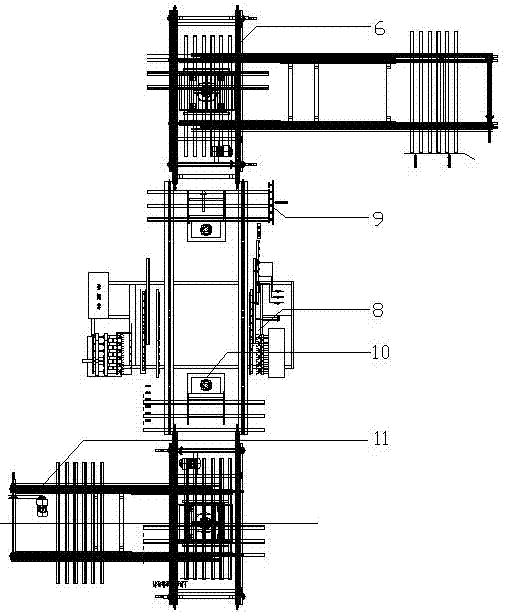

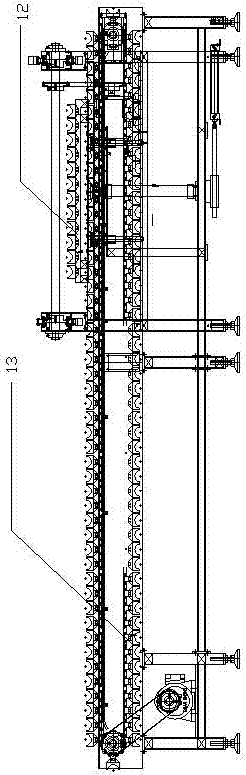

[0034] As shown in the accompanying drawings, the present invention is a device for automatic loading and unloading of glass heat collecting tube tailing machine equipment, including a digital line 2 arranged and connected in sequence, a synchronous belt-transplanting device 3, and an upper tube top roller chain conveyor line 4. Upper tube lifting and rotating 90 degree mechanism 5. Upper tube top rolling chain conveying 6. Upper tube lifting and hosting transplanting mechanism, neat blank tube mechanism 9. Automatic tail pulling machine equipment 8. Lower tube jacking and hosting transplanting Mechanism 10, upper layer lower pipe top roller chain conveying line 11, lower pipe jacking and rotating 90 degree mechanism 12 and lower pipe top roller chain conveying line 13.

[0035] The position of the glass tube on the chain plate of the bridge line is irregular and random. The distance between the glass tube and the glass tube is one or several, which is irregular. By setting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com