All-in-one assembling machine for road construction

A road construction and all-in-one technology, which is applied in the field of high-efficiency assembling special all-in-one machine for prefabricated road base construction, can solve the problem of long empty return distance of assembled crane boom, raising the overall cost of road construction, and inability to realize half-width road operations, etc. problems, to achieve the effect of low operation and maintenance costs, high paving efficiency, and increased skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

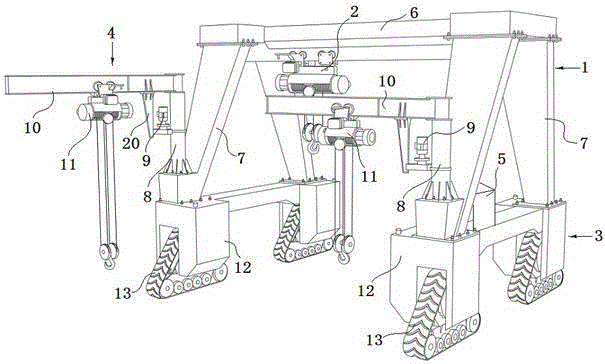

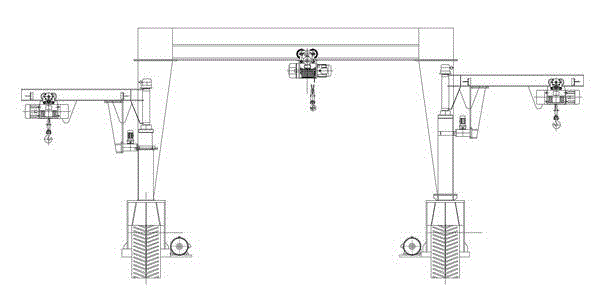

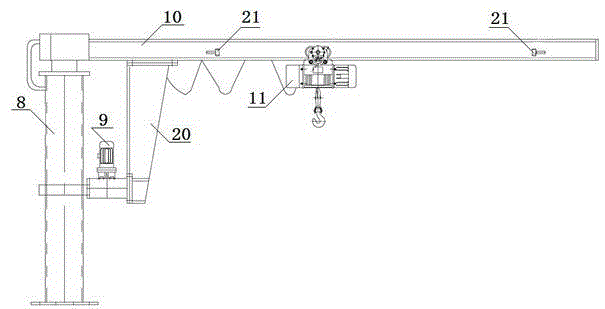

[0016] attached by figure 1 , 2 As shown: the all-in-one machine includes a truss 1, a main crane 2, a crawler-type traveling mechanism 3, a cantilever crane assembly 4 and an electric control box 5. The truss 1 is composed of a main beam 6 and two ends of the main beam 6. The two vertical beams 7 of the glyph structure are formed, the main crane 2 is arranged on the main beam 6 of the truss 1, and the crawler type traveling mechanism 3 is arranged under each vertical girder 7 of the herringbone structure, and the two cantilever Hanging assembly 4 is arranged on one side of the vertical beam 7 of each herringbone structure, and described cantilever hanging assembly 4 is made of independent column 8, independent column rotating motor 9, the cantilever 10 that is arranged on the independent column 8 and is arranged on the cantilever 10 The upper cantilever crane 11 is formed, and the crawler-type traveling mechanism 3 is composed of a traveling mechanism frame body 12 and two t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com