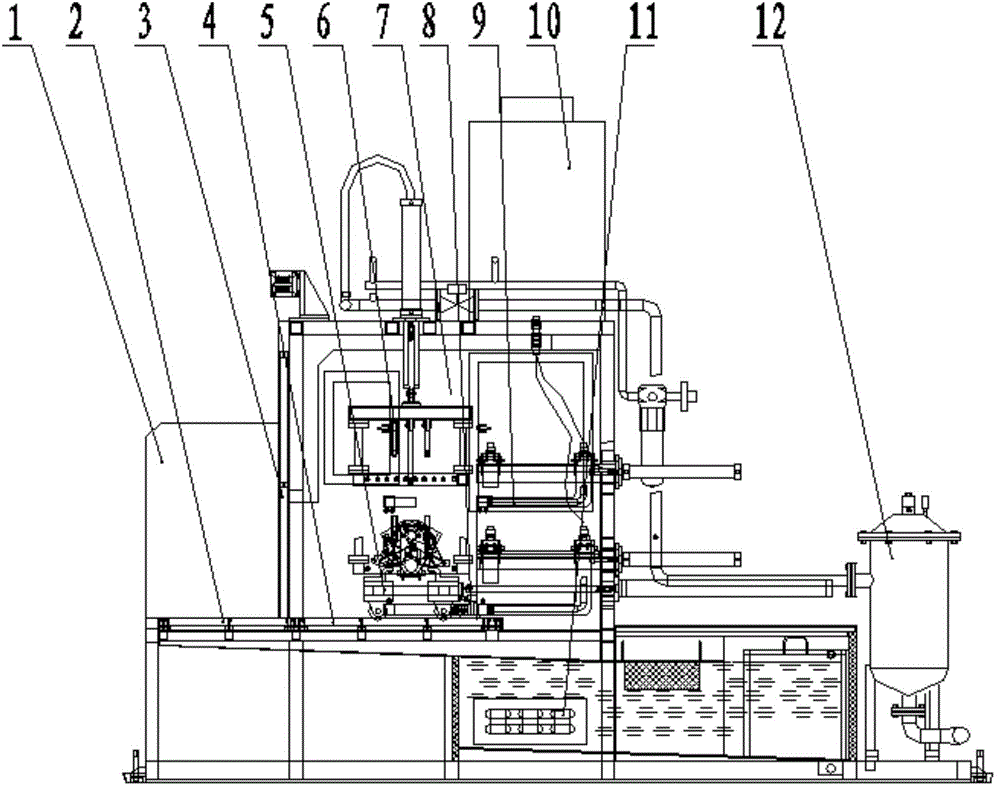

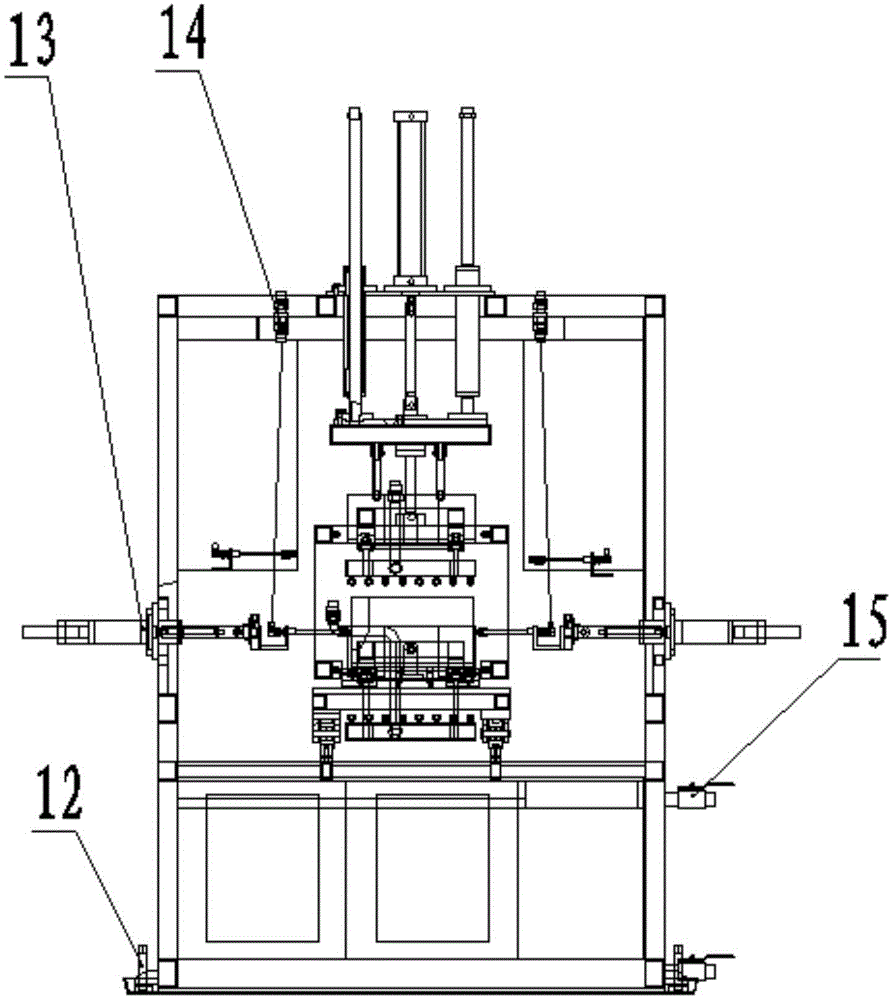

Cylinder body cleaning machine

A technology for cleaning machines and cylinders, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low production efficiency, difficult to clean the internal cavity of the body, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

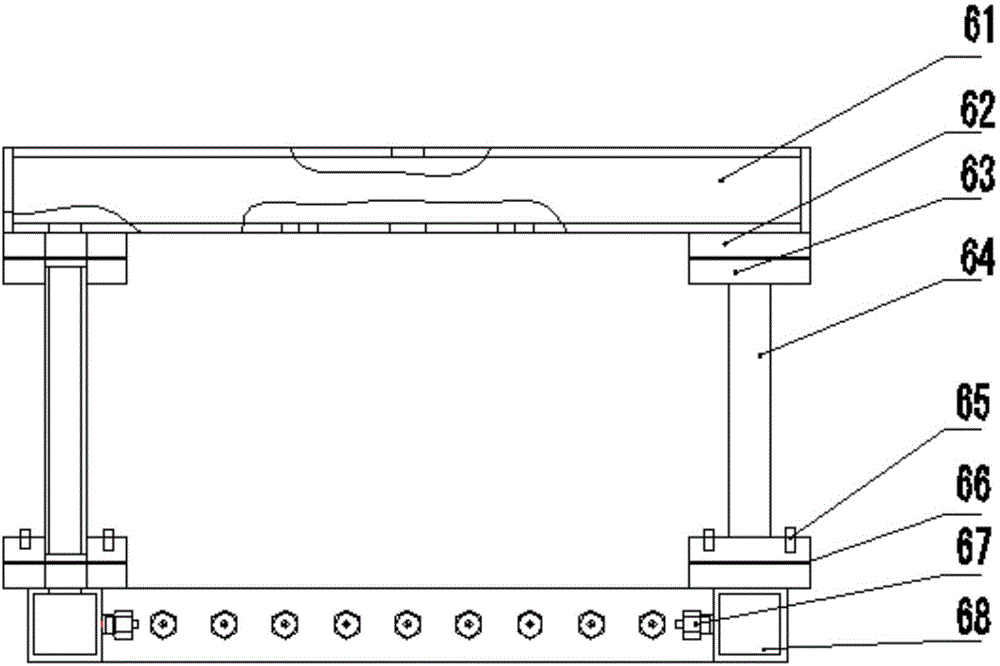

[0049] The nozzle 68 is rectangular in shape.

Embodiment 2

[0051] The nozzle 68 is in the shape of a "cross".

[0052] Such as Figure 4 As shown, the horizontal spray box 9 includes a support rod, a coupling frame, a horizontal spray pipe, a coupling rod 98 and a cylinder 94, and the support rod includes a horizontal support rod 912 and a vertical support rod 911, and the horizontal support rod 912 is fixed on the vertical support On the rod 911, the angle between the horizontal support rod 912 and the vertical support rod 911 is 90°; the horizontal support rod is connected with the cylinder 94 through the coupling rod 98; the coupling frame is fixed on the horizontal support rod 912, and the horizontal spray The pipe is fixed inside the coupling frame; the end of the horizontal nozzle is provided with a nozzle; the coupling rod 98 and the cylinder 94 are fixed with a sealing ring 97; the horizontal support rod 912 includes an upper horizontal support rod and a lower horizontal support rod; The horizontal nozzle includes an upper ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com