Heating radiator

A radiator and heating technology, which is applied to household heating, heating methods, heating systems, etc., can solve the problems of increasing the production cost of oil production enterprises, waste of human and material resources, and scattered oilfield rooms, and achieves a simple structure and reduced energy consumption. The effect of energy consumption and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

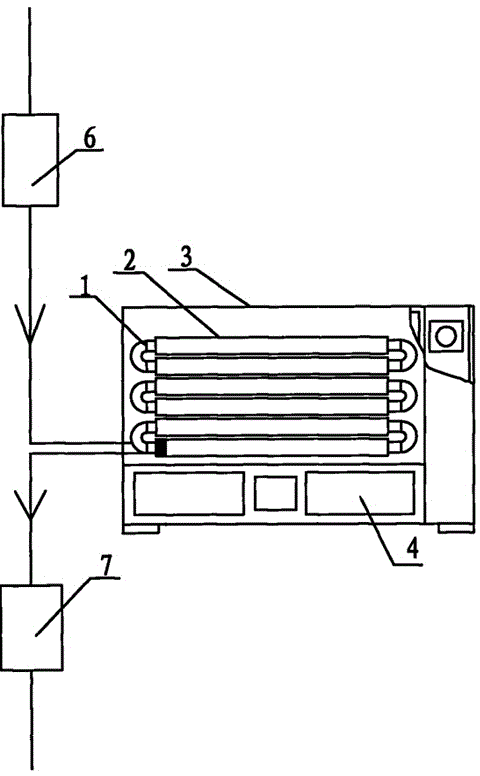

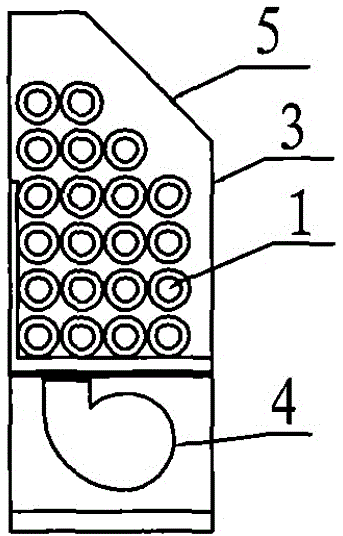

[0010] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0011] Such as figure 1 with figure 2 As shown, a heating radiator of the present invention includes a housing 3, a heat dissipation coil 1 and a blower 4 for blowing out the heat emitted by the heat dissipation coil 1 are arranged in the housing 3, and the upper part of the housing 3 is provided with The cooling outlet 5, the cooling outlet 5 can be arranged on the top surface of the housing 3 or on the side of the housing 3, the water inlet end of the cooling coil 1 is connected with the water treatment station 6 of the thermal recovery oil well, and the cooling coil The water outlet of 1 is connected to the steam boiler 7 of the thermal recovery oil well, and the hot water treated by the water treatment station 6 enters the heat dissipation coil 1, and the heat is dissipated through the heat dissipation coil 1, and the returned water after the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com