A heat-conducting and heat-dissipating plate assembly for a heating heat exchanger with a tube-row structure

A heating heat exchanger and heat sink technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problems that affect the user's recognition of products, small heating and heat dissipation area, monotonous appearance, etc. Excellent heat exchange performance and heat dissipation performance, heating effect improvement, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe the present invention in detail below in conjunction with accompanying drawing and embodiment.

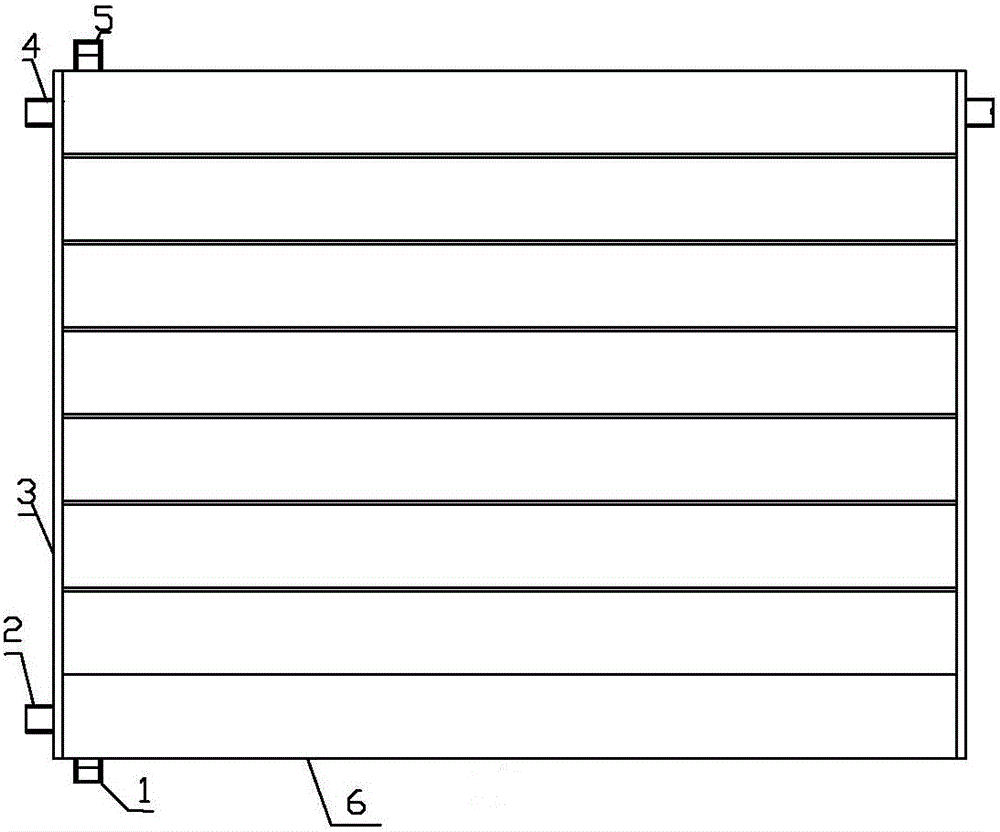

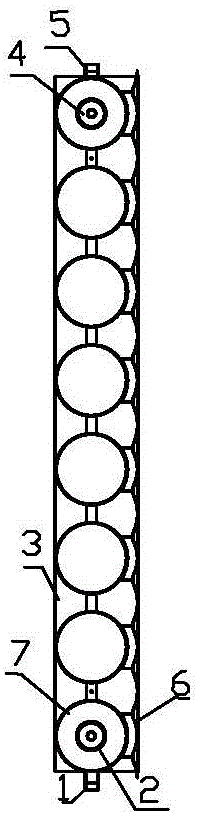

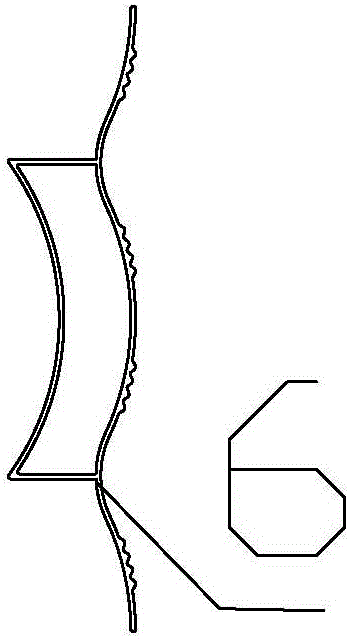

[0022] Such as figure 1 , figure 2 Shown: a combination of heat conduction and heat dissipation plates for a heating heat exchanger with a tube row structure. Its tube row structure includes a plurality of parallel arranged round tubes, for example figure 2 7 in the middle, its diameter can be 76, 85, 90 millimeters etc., quantity is like 6, 8, also includes the communication device that can be arranged on the two ends of round tube 7 and can connect each round tube fixedly into the shape of tube row, communication device It is usually round tube, D-shaped, mouth-shaped, and the special-shaped shape (combined by connecting pipe, connecting pipe and round pipe head) in the inventor's two existing invention patents. The round pipe 7 and the communicating device All adopt thin-walled stainless steel materials, and the radiator of this pipe row structure is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com