Novel automatic-positioning pipe-sleeved-pipe connection structure and assembling method

A technology of connecting structure and pipe casing is applied in the field of connecting structure design of fuel assemblies of pressurized water nuclear reactors, which can solve the problem of undetermined expansion joint position, and achieve the effects of preventing relative rotation, facilitating assembly, and providing bearing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

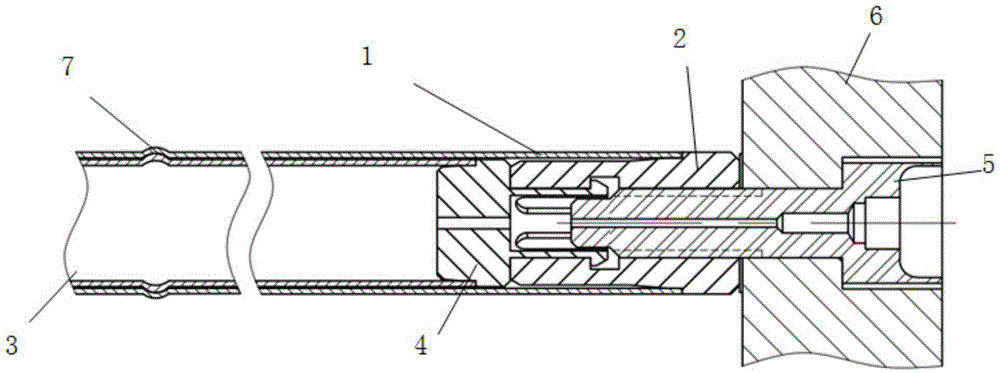

[0030] Such as figure 1 As shown, the connection structure of some embodiments of the present invention is composed of a conduit 1 , a conduit end plug 2 , a buffer tube 3 , a buffer tube end plug 4 , a screw 5 , and a lower tube seat 6 .

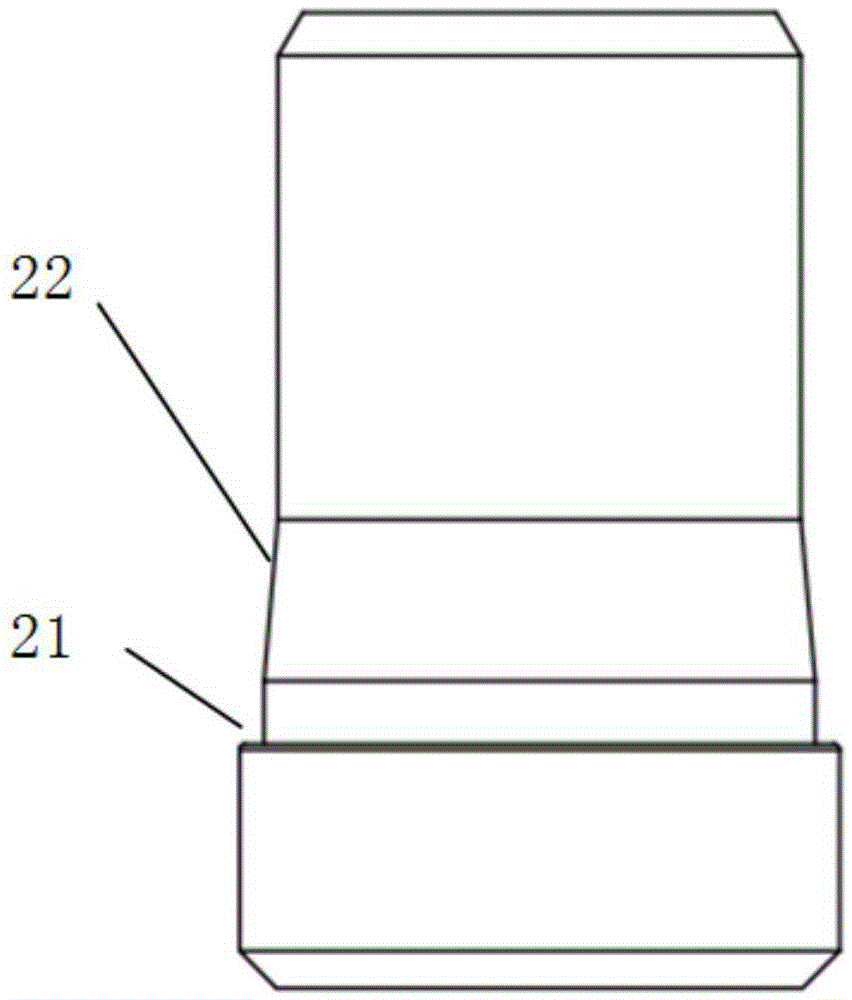

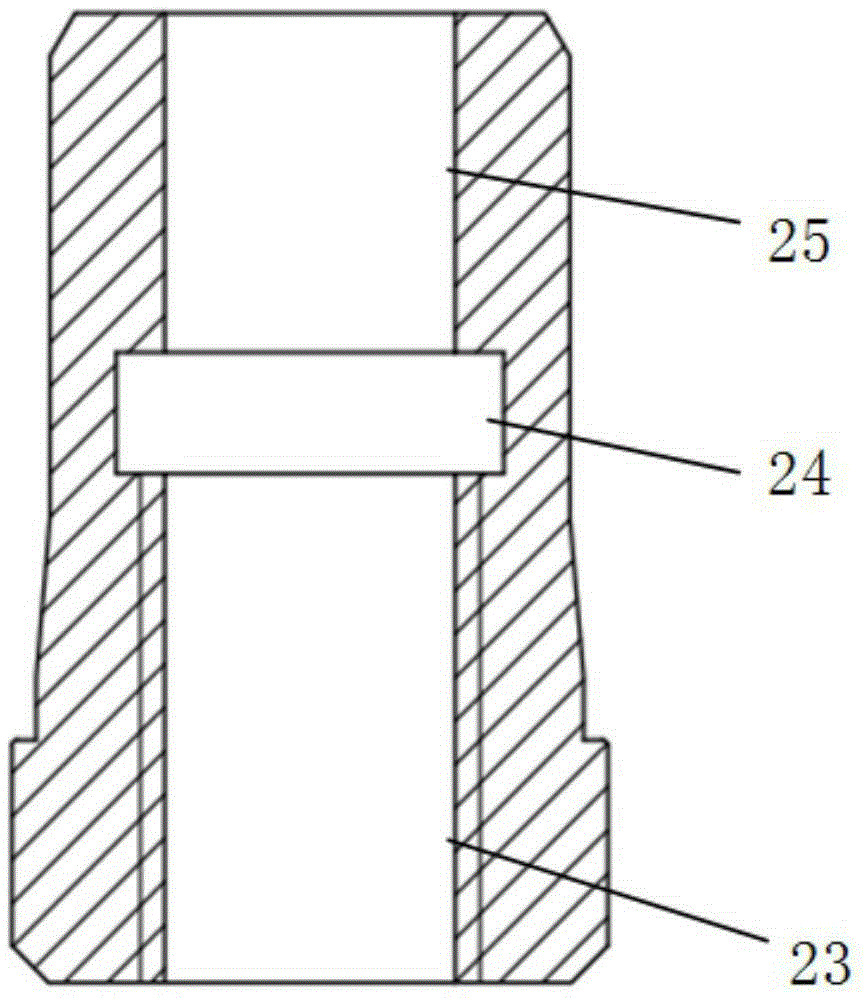

[0031] The catheter 1 is a straight pipe with an inner diameter of about 10mm-12mm and an outer diameter of about 11mm-14mm. The catheter end plug 2 is in the shape of a short rod with a length of about 16 mm to 25 mm. The outer surface is designed with a first step 21 for matching with the conduit 1, and the conduit 1 can be connected with the conduit end plug 2 by welding. At the same time, the first transition section 22 is designed with an angle of about 3-10° and a length of about 2-5 mm. The first transition section 22 facilitates the insertion of the catheter 1 into the catheter end plug 2 . The conduit end plug 2 has a hole in the center, and a threaded connection section 23 is designed at the lower end, which can be an M5 or M6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com