An easy-to-disassemble heat sink structure of a transformer

A heat sink and transformer technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems that dust and oil stains are easy to stick to the heat sink, affect the performance of the heat sink, and reduce the heat dissipation efficiency, etc., and achieve easy disassembly, easy cleaning, and heat transfer good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

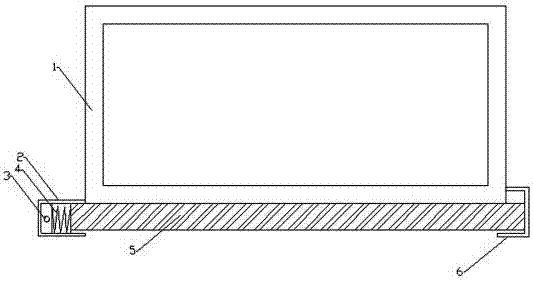

[0025] The heat sink structure of the transformer, such as figure 1 As shown in the top view, a first groove 2 is provided at one end of the outer side of the heat transfer oil chamber 1, and a second groove 6 is provided at the other end. The openings of the first groove 2 and the second groove 6 are mutually Orientation, a rotating shaft 3 is also provided on the first groove 1, an elastic member 4 (spring) is also provided inside the first groove 2, and a cooling fin 5 is also included, and one end of the cooling fin 5 is arranged in the first concave In the open opening of the slot 2, it is tightened by a spring so that the other end of the cooling fin 5 is located inside the second slot 6.

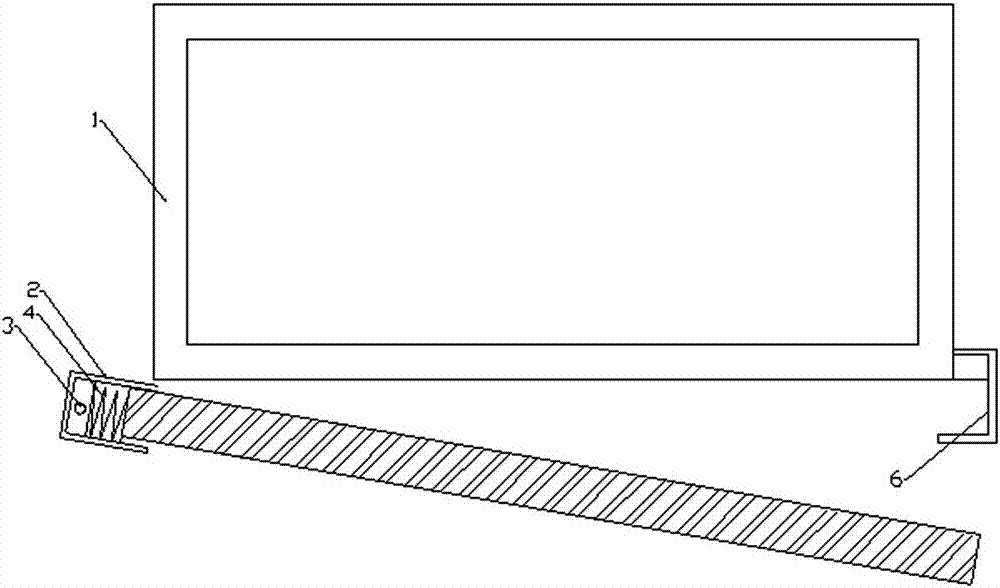

[0026] When the heat sink 5 needs to be disassembled, such as figure 2 As shown, the cooling fin 5 is pressed to the left so that the spring is tightened, and then the first groove 2 is rotated to rotate the cooling fin 5 to an angle, so that the cooling fin 5 can be pulled out conv...

Embodiment 2

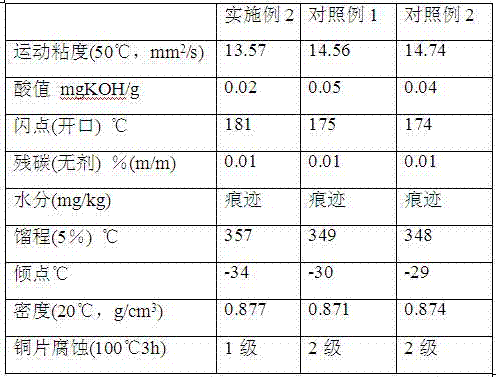

[0029] The heat transfer oil is made of the following components by weight: 10 parts of sunflower oil, base oil (the kinematic viscosity at 100°C is 20-35mm 2 / s mineral oil) 90 parts, 2-aminoethyl heptadecenyl imidazoline 5 parts, glyceryl triacetate 5 parts, 2,6-tert-butyl p-cresol 2 parts, rust inhibitor dodecenyl 3 parts of succinic acid, 3 parts of surfactant isomeric tridecanol polyoxyethylene ether, 3 parts of dispersant polyalkenyl succinimide, 3 parts of antioxidant thiophosphobutyloctyl zinc salt; the preparation method is , mix each component evenly, heat up to 50-60°C, stir, and let cool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com