Magnetic resistance element and electronic device

A technology of resistive elements and electronic devices, applied in the direction of magnetic field-controlled resistors, etc., can solve the problems of low magnetic sensitivity, difficulty in using large magnetic field sensing arrays, and low mobility of carriers, and achieve the effect of high magnetic sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

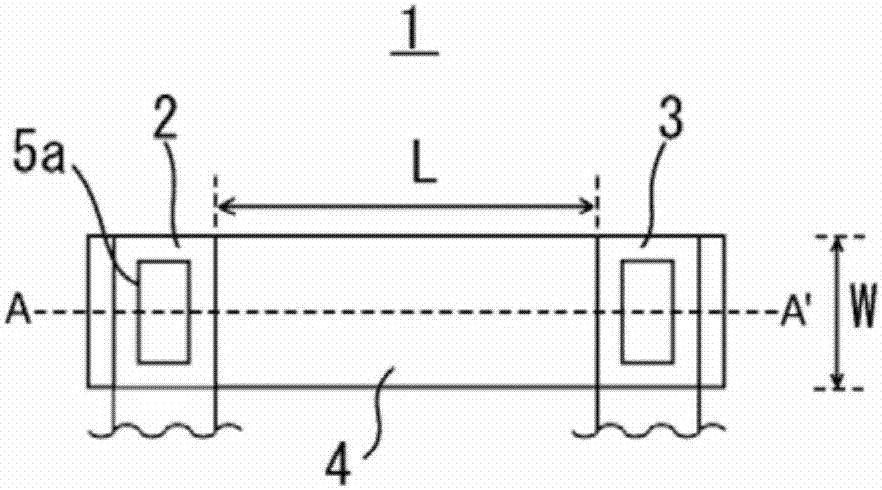

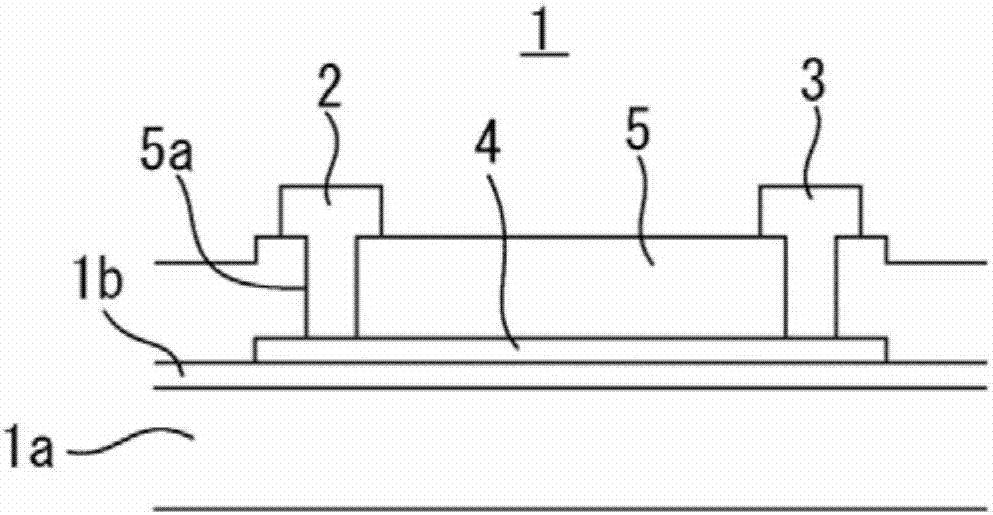

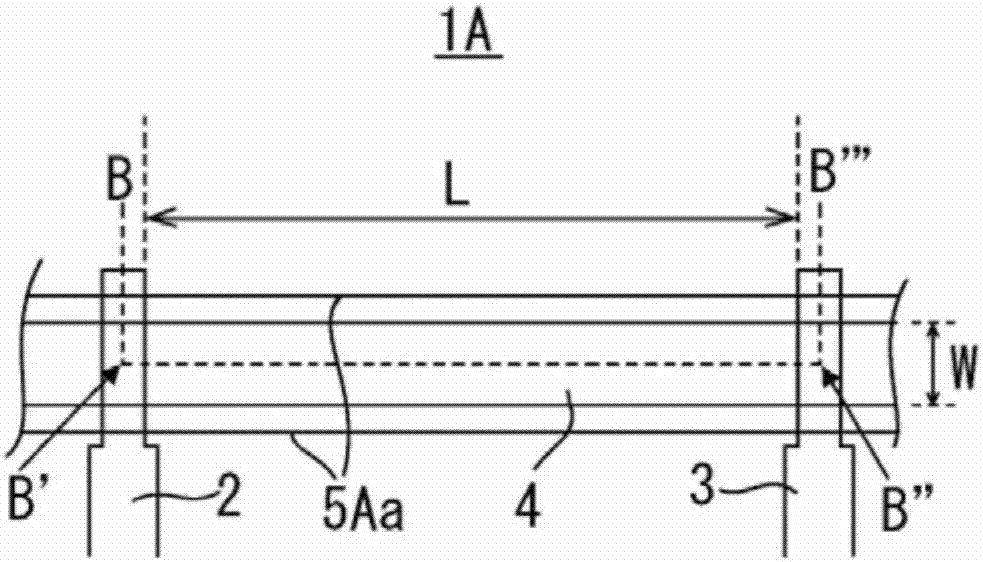

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The magneto-resistive element 1 according to the embodiment of the present invention, as shown in FIG. The inductive resistance layer 4 , the magneto-inductive resistance layer 4 flows a current after a voltage is applied between the first electrode 2 and the second electrode 3 , and the resistance value changes according to the intensity of the magnetic field. The magnetoresistive layer 4 is formed by patterning an amorphous indium gallium zinc oxide (IGZO) thin film. In addition, patterning is to form a film into a desired shape, usually by etching, but the method is not limited.

[0045] Amorphous IGZO is composed of In, Ga, Zn and oxygen elements, and is an amorphous oxide with semiconductor properties. When this amorphous IGZO is used for the magnetoresistive layer 4, the magnetic sensitivity of the magnetoresistive element 1 can be improved even if the magnetoresi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com