Carbon brush assembly for motor

A technology of carbon brushes and components, which is applied in the direction of electrical components, circuits, current collectors, etc., can solve the problems of product heat dissipation reduction, motor malfunction, and occupying the internal space of the motor, etc., so as to improve the life of the motor, improve electromagnetic compatibility, The effect of increasing the life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments.

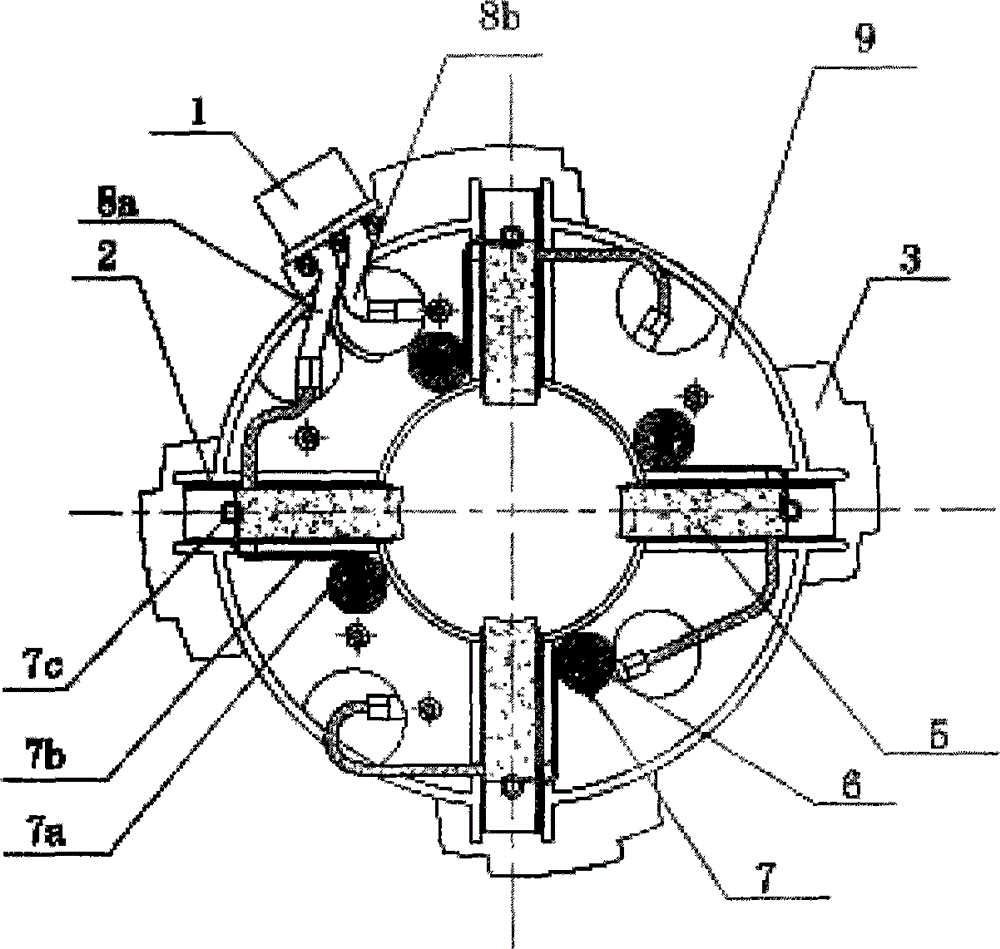

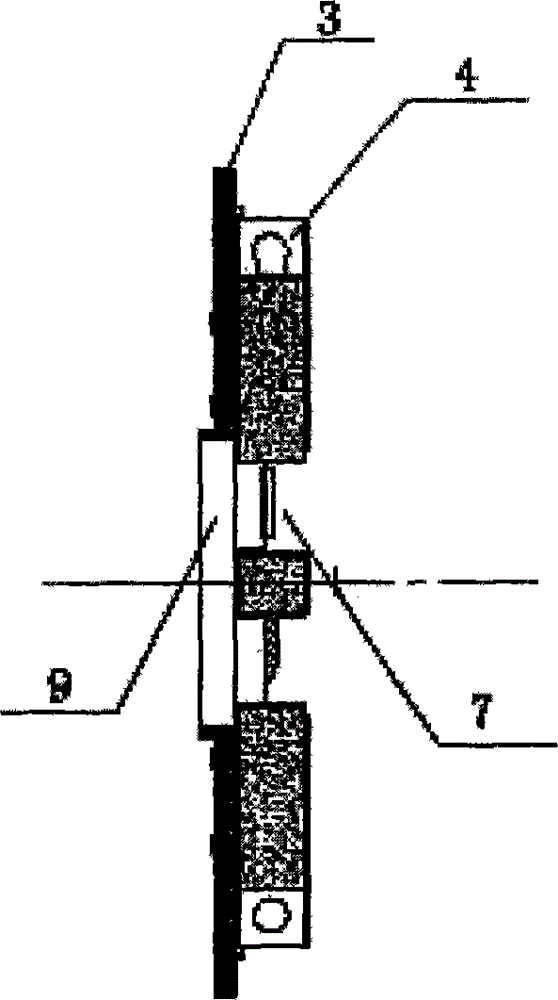

[0014] A carbon brush assembly for motors such as figure 1 As shown, it includes a carbon brush plate 3, a carbon brush box 4, a carbon brush 5, a scroll spring 7, and a carbon brush holder 9, wherein the carbon brush box 4 is a groove structure, and the carbon brush 5 is located in the carbon brush groove, which can be vortexed again. Under the action of the coil spring, it is in close contact with the commutator. When it is worn out, the coil spring pushes the carbon brush forward to prolong the service life of the motor. The carbon brush plate 3 supports the carbon brush frame 9, the carbon brush and the carbon brush box are located on the carbon brush frame, the outer end of the carbon brush box 4 spans the junction of the carbon brush frame 9 and the carbon brush plate 3, and the carbon brush box 4 outer end 1 / 4 parts are located on the carbon brush plate 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com