Power supply circuit for modified-Siemens-process polycrystalline silicon production device

A technology of production equipment and the Siemens method, applied in the direction of circuit devices, emergency power supply arrangements, electrical components, etc., can solve problems affecting production capacity, high failure rate, and affecting production efficiency, so as to avoid equipment damage, improve production efficiency, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

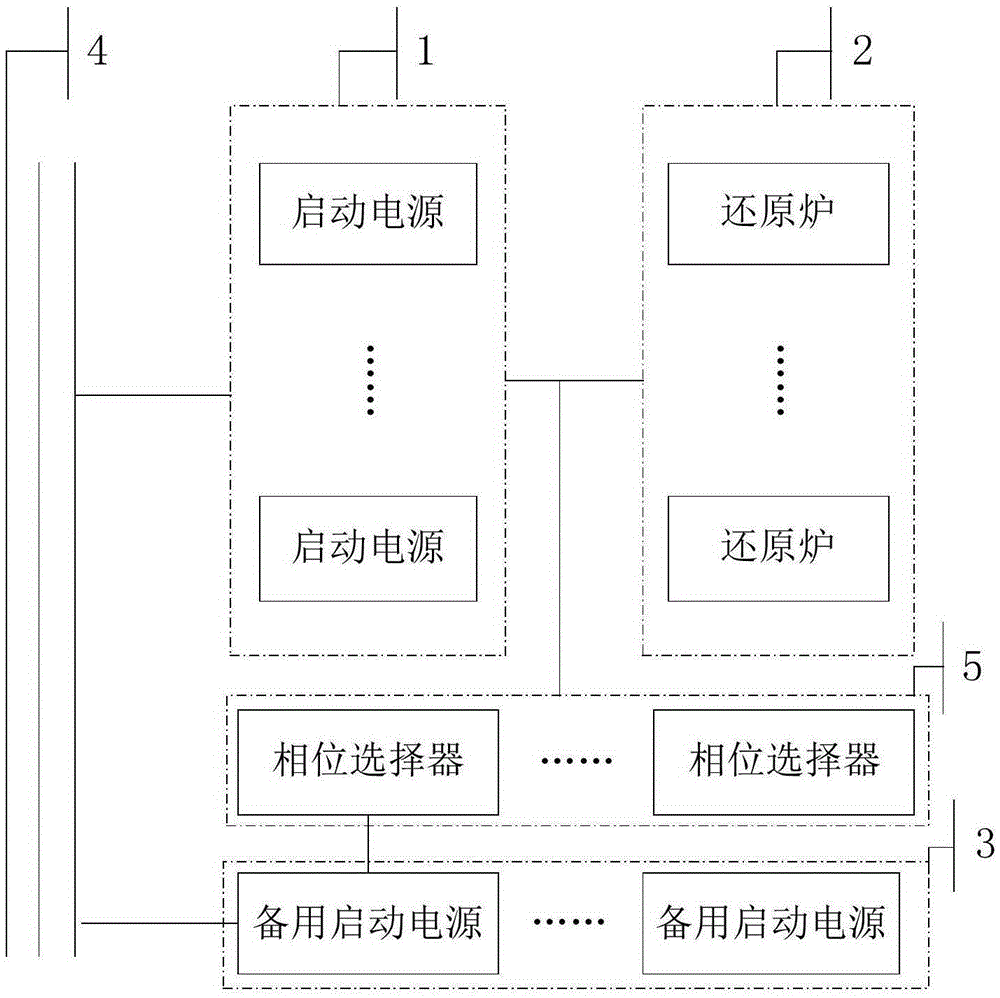

[0026] figure 1 Shown is a block diagram of a power supply circuit of an improved Siemens method polysilicon production equipment according to a specific embodiment of the present invention, including a power supply system composed of several reduction furnaces, N starting power supplies, and K standby starting power supplies, wherein the N The start-up power supply of the K sets and the standby start-up power supply of the K sets are connected to the three-phase power transmission circuit at the same time;

[0027] The output terminals of the power supply system are connected to the plurality of reduction furnaces, and each of the K standby starting power supplies is connected to the output terminals of the power supply system through a phase selector. When any of the N starting power supplies When one of the backup starting power supplies is damaged, any one of the backup starting power supplies can adjust its output phase to match the output phase of the damaged starting p...

Embodiment 2

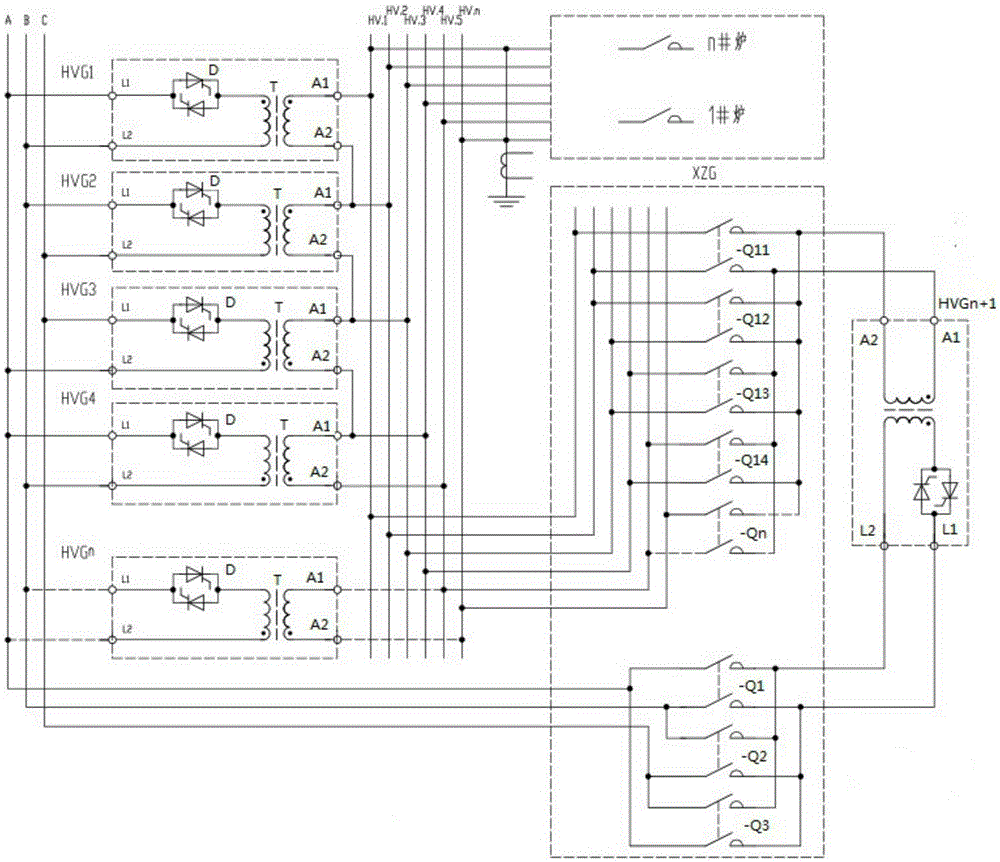

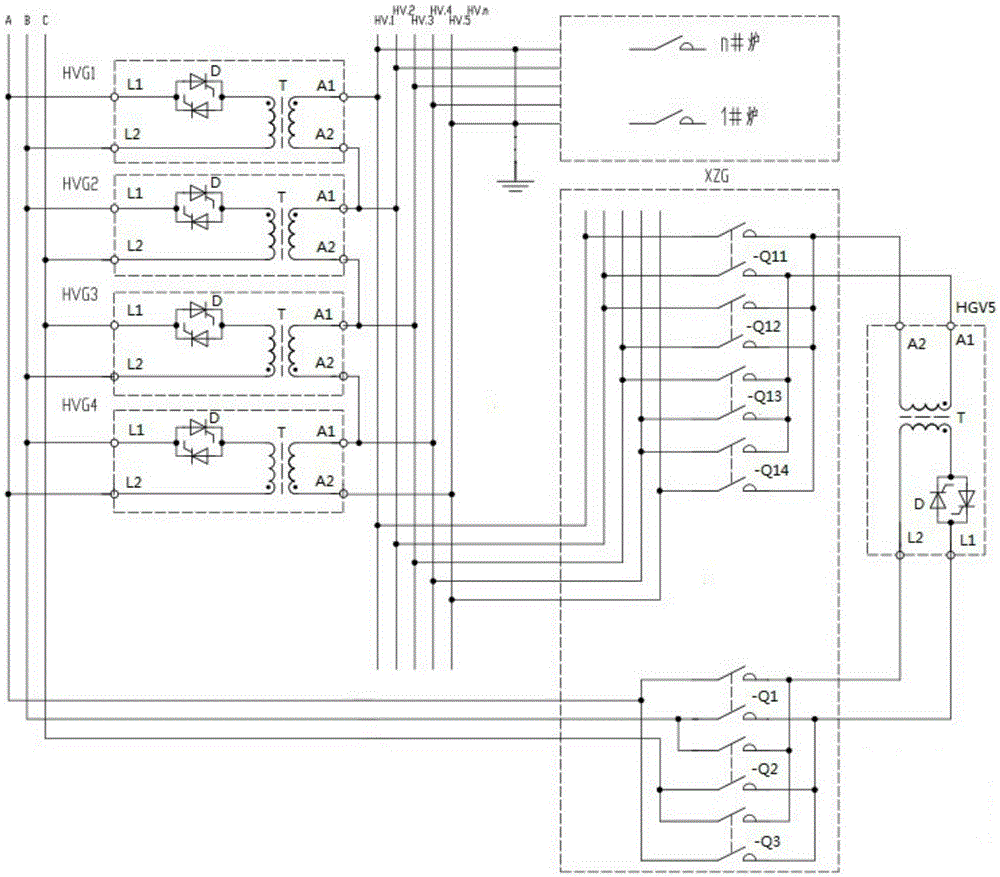

[0039] In order to better illustrate the specific working principle of the circuit of the present invention, image 3 The circuit connection diagram of the 4+1 master-standby switching mode is given, and its connection mode is similar to that of the n+1 master-standby circuit of the present invention, and will not be repeated here.

[0040] Specifically, see image 3 , when HVG1 fails, the standby system starts the phase selector XZG, -Q1 and -Q11 are connected, and the input and output phases of HVG5 are consistent with HVG1, completely replacing HVG1;

[0041] When HVG2 fails, the standby system starts the phase selector XZG, -Q2-Q12 is connected, and the input and output phases of HVG5 are consistent with HVG2, completely replacing HVG2;

[0042] When HVG3 fails, the standby system starts the phase selector XZG, -Q2-Q13 is connected, and the input and output phase of HVG5 is consistent with that of HVG3, completely replacing HVG3;

[0043] When HVG4 fails, the backup syst...

Embodiment 3

[0045] Figure 4 Shown is a schematic block diagram of a power supply circuit of an improved Siemens method polysilicon production equipment with ground detection according to a specific embodiment of the present invention. The content, the difference is only: the electrodes L and H of the reduction furnace are connected together and connected to the protective ground, and the current detection device PT is between the two pole connection points and the protective ground, and is used to detect whether the electrical insulation of the reduction furnace is damaged.

[0046] Further, it also includes a current detection device, one end of the current detection device is grounded, and the other end is connected to any electrode drawn from the reduction furnace to form a loop for detecting whether the electrical insulation of the reduction furnace is damaged.

[0047] Further, the current detection device is a current transformer.

[0048] In order to better illustrate the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com