Harvesting machine for caragana microphylla seeds

A technology for harvesting machines and seeds, applied in the directions of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of reduction in the rate of harvesting, consumption, large manpower, etc., so as to reduce the cost of harvesting, improve the harvesting efficiency, The effect of high travel speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

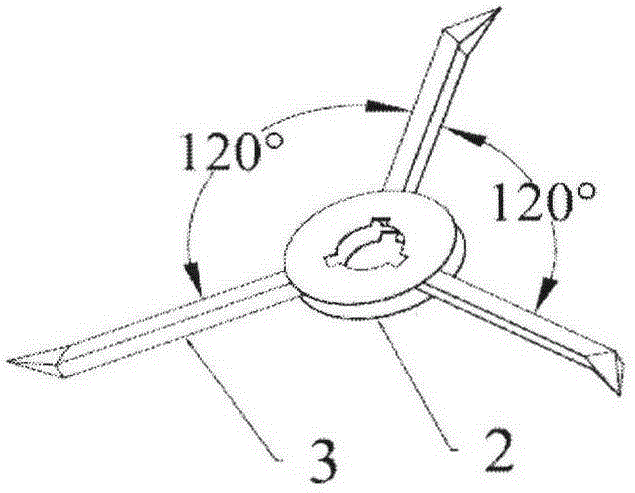

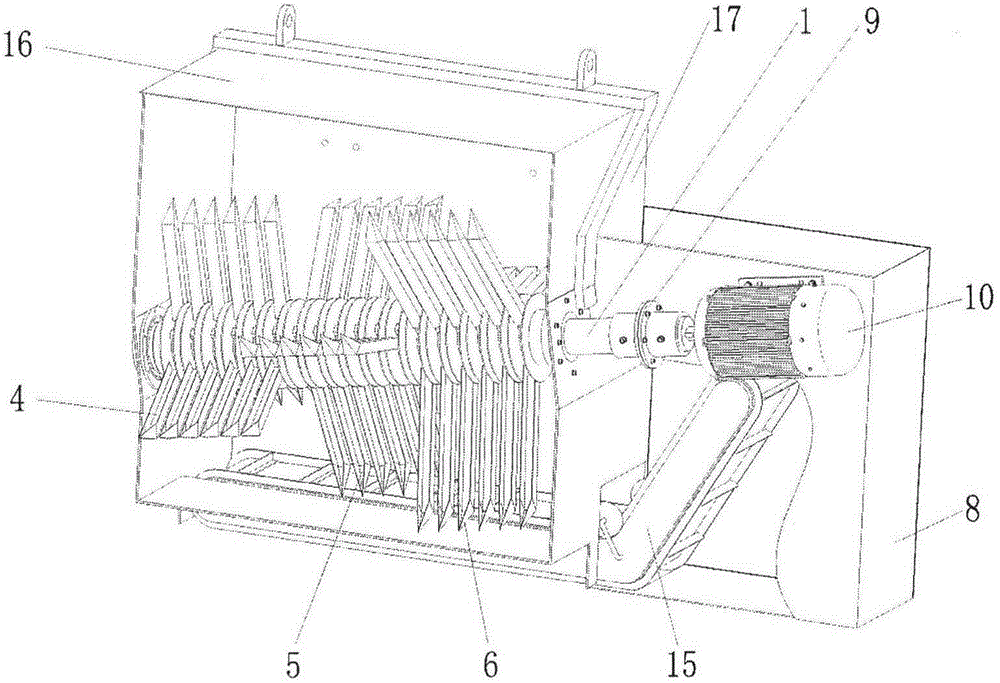

[0025] see figure 1 , figure 2 In the caragana seed harvester shown, the outer circumference of the rotating shaft 1 that mainly transmits power has three protrusions extending along the axis direction, which are shaped like flat keys; A groove shaped like a keyway, the two cooperate to transmit torque, and three comb teeth 3 are fixed on the outer surface of the comb holder 2 to form a collector. The comb holder 2 can slide along the axis direction along the surface of the rotating shaft 1, and the gap between the comb teeth 3 along the axis direction can be set by adjusting the washer. The lengths of the combs in the collector assemblies with serial numbers 4, 5, and 6 increase successively, and the angles of their combs in the circumferential direction of the rotating shaft differ by 40°, that is, 360° / (3×3); the rotating shaft 1 The two ends of the motor are rotatably supported on the frame, and are connected with the output shaft of the motor 10 through a coupling 9 . ...

Embodiment 2

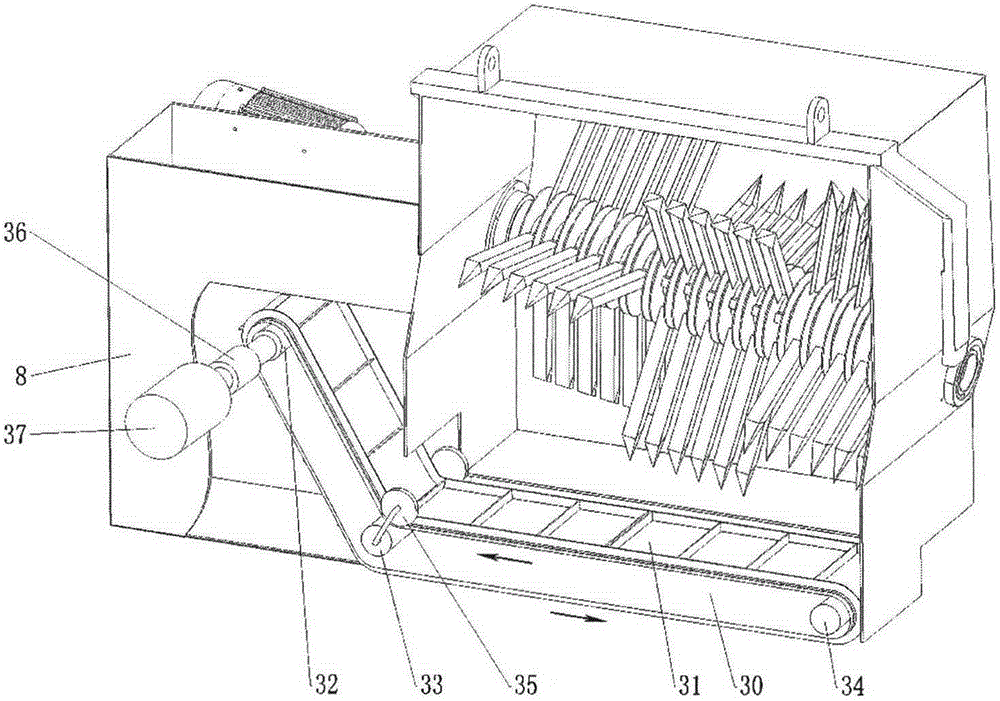

[0031] Figure 6 The difference between shown embodiment 2 and embodiment 1 is: the conveying mode that fruit pod is transported in the storage box adopts screw conveyor and blower fan 23 to be respectively responsible for the horizontal conveying of fruit pod and seed and vertical promotion, wherein The screw conveyor consists of a shaft 21 with a helical surface, a semicircular bottom plate 22 and bearings 20 at both ends, and its driving device is composed of a motor 10 and a shaft coupling 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com