Fast after-ripening fermentation technology based on mucor fermented soybean characteristic flavor

A post-ripening fermentation, mucor-type technology, applied in food science and other directions, to achieve the effect of simple and easy method, shortening fermentation cycle, and improving characteristic flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: Douchi fermented and aged for 2 years (naturally matured Douchi)

[0019] Bean selection: soybeans are used as raw materials, and soybeans require full grains. Soaking: Soak soybeans in water for 5-6 hours and drain. Cooking: The drained soybeans are steamed at 121°C for 30 minutes. Cooling inoculation: After the cooked soybeans are cooled to 40°C, inoculate 0.5% Mucor koji according to the mass of soybeans, and cultivate them at 10-15°C for 7 days to make tempeh koji. Mixing material: After making the koji, add 12% NaCl, 3% edible starch and 5% white wine according to the quality of the koji. Post-ripening fermentation: put the mixed koji into a sealed container, and naturally ferment and age for 2 years.

example 2

[0020] Example 2: Douchi fermented for 30 days (enhanced fermented Douchi)

[0021] Bean selection: soybeans are used as raw materials, and soybeans require full grains. Soaking: Soak soybeans in water for 5-6 hours and drain. Cooking: The drained soybeans are steamed at 121°C for 30 minutes. Cooling inoculation: After the cooked soybeans are cooled to 40°C, inoculate 0.5% Mucor koji according to the mass of soybeans, and cultivate them at 10-15°C for 7 days to make tempeh koji. Mixing material: After making the koji, add 12% NaCl, 3% edible starch and 5% white wine according to the quality of the koji. Fermentation after inoculation of salt-tolerant microorganisms: the koji base (calculated as 1000g) mixed with the ingredients was simultaneously inserted into Luxie yeast CGMCC3791 (2.3×10 6 CFU / g), Candida CGMCC3790 (4.7×10 7 CFU / g) and tetradococcus halophilus CGMCC3792 (4.3×10 7 CFU / g), and fermented at 40°C for 30 days.

example 3

[0022] Example 3: Comparison of Volatile Components of Naturally Ripened and Fortified Fermented Douchi

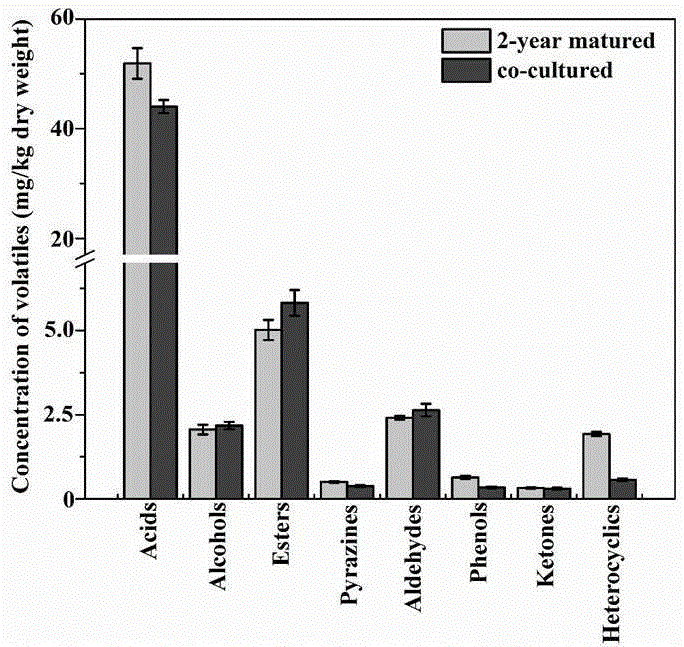

[0023] A total of 8 types of volatile compounds were detected by headspace solid-phase microextraction and gas chromatography-mass spectrometry for naturally mature and enhanced fermented tempeh. Among them, there are small differences in the contents of acids, esters and heterocyclic compounds between the two kinds of tempeh, while the alcohols, aldehydes, phenols, ketones, pyrazines and furans that have a greater contribution to the characteristic flavor of tempeh Compounds were not significantly different ( figure 1 ).

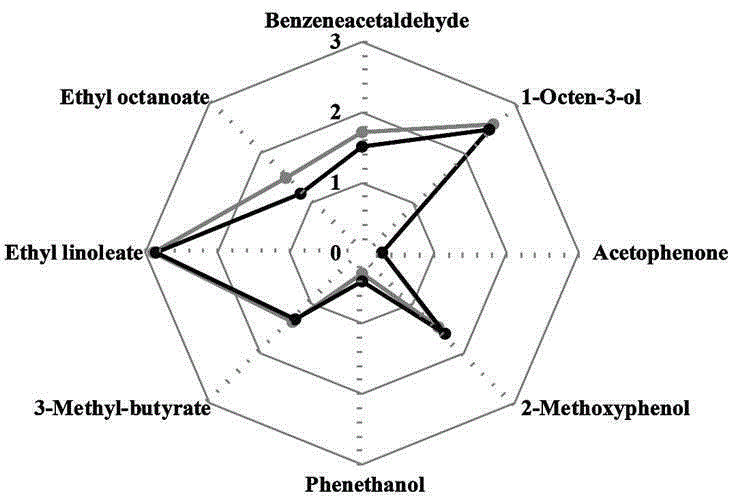

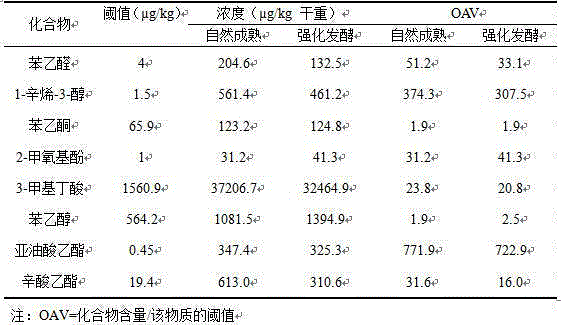

[0024] Eight volatile components that contributed to the characteristic flavor of Douchi were selected for odor activity value analysis (OAV), and the results are shown in Table 1. Among them, the OAV of ethyl linoleate, which imparts sweet and oily flavor to tempeh, was the largest, and the OAV of natural ripening and enhanced fermentation were 771....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com