Grading regulation and control method of high-order flatness defect of ultra-thin cold-rolled strip steel with high width-to-thickness ratio

A high-order shape and cold-rolled strip technology, applied in the direction of contour control, can solve the problems that affect the training time and recognition accuracy, the key parameters are not easy to accurately determine, and the shape signal cannot be truly reflected, so as to improve the quality of the shape , reduce the amount of calculation, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

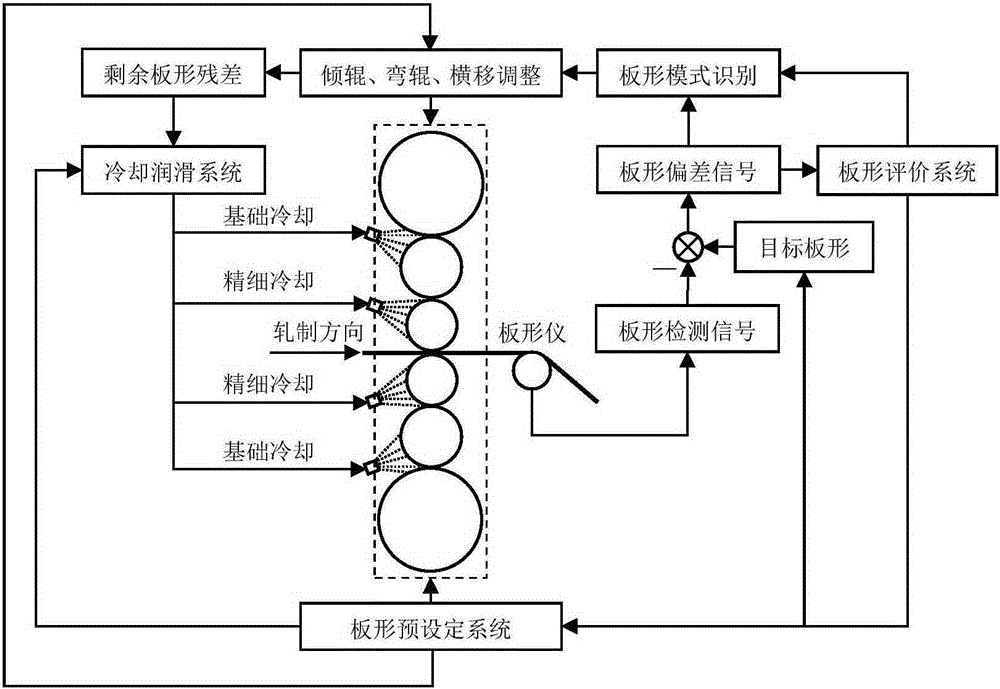

[0030] According to the present invention, a hierarchical control method for local high-order shape defects of ultra-thin cold-rolled steel strips with a large aspect ratio, the basic process of the comprehensive control of the shape is as follows: figure 1 As shown, the method includes the following steps:

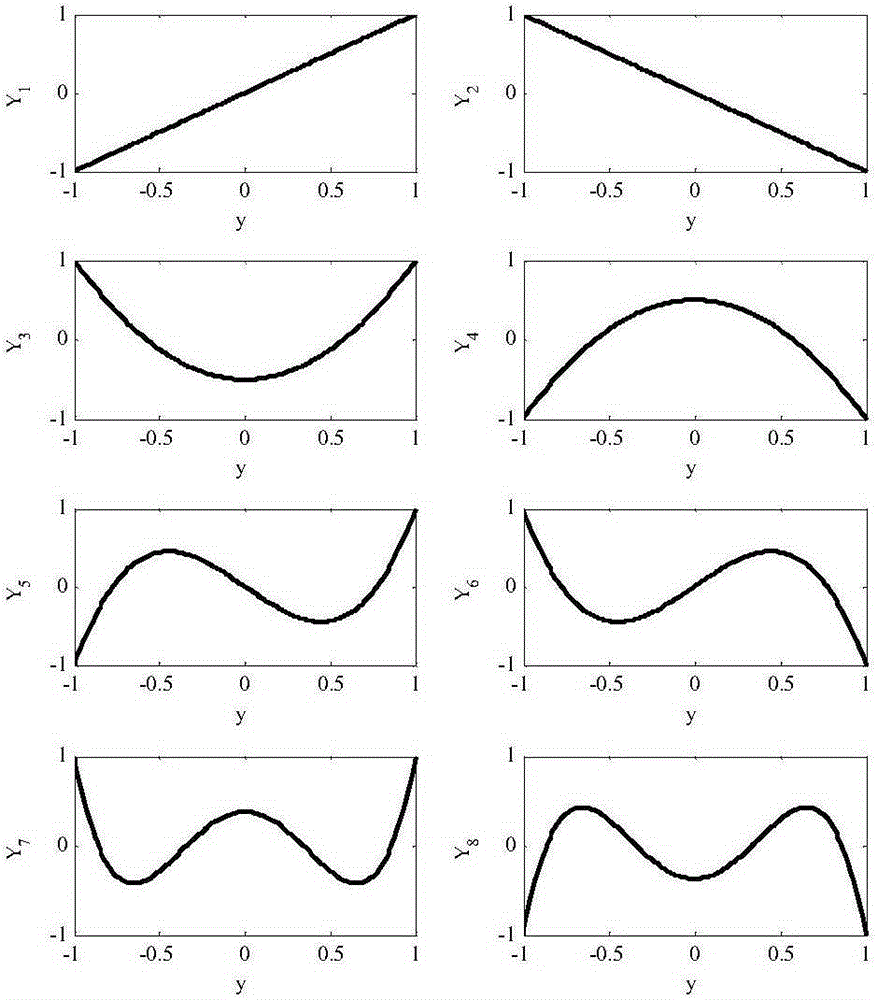

[0031]1. Establish a plate shape pattern recognition model based on ultra-high-order Legendre orthogonal polynomials:

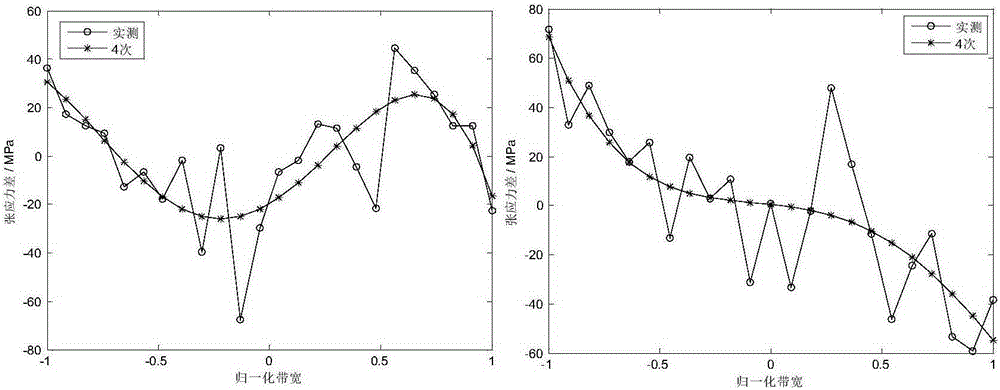

[0032] Assuming that the number of effective channels of the plate shape detection roller is m, y∈[-1,1] represents the normalized plate width coordinates, and the origin is located at the center of the plate width, the measured value is expressed as Δσ 1 (y)=[Δσ 1 (-1)Δσ 1 (y i )…Δσ 1 (1)], if the target curve Δσ is known * (y), then the target deviation value Δσ i (y) for

[0033] Δσ i (y) = Δσ 1 (y)-Δσ * (y)(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com