Air control device and control method for large-scale vacuum pressurized casting equipment

A technology for casting equipment and air control, which is applied in the field of air control devices for large-scale vacuum pressurized casting equipment, can solve problems such as poor control accuracy, achieve the effects of reducing casting defects, enhancing solidification feeding ability, and improving pressure difference control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

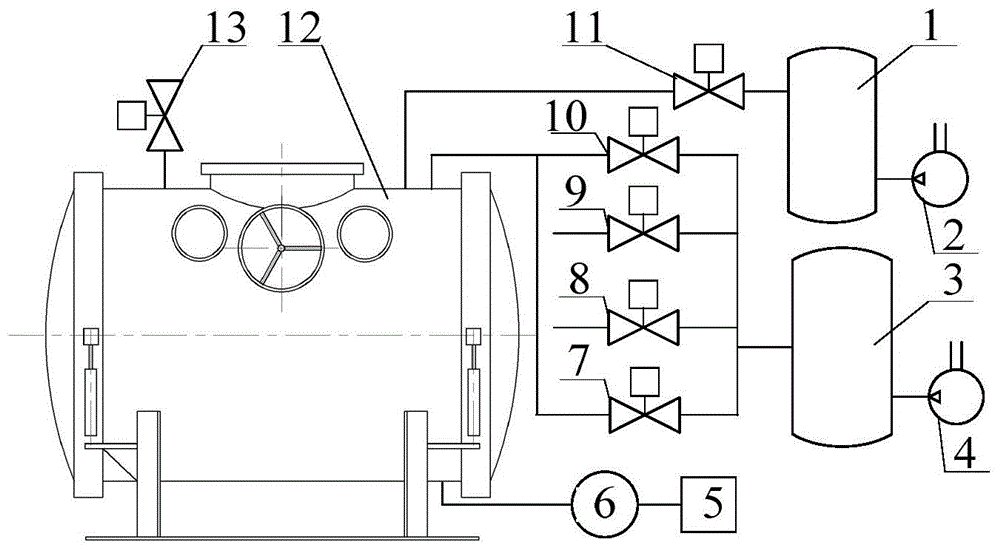

[0020] Example 1. The air control device of the large-scale vacuum pressurized casting equipment of the present invention includes a vacuum buffer tank 1, a vacuum pump 2, an air storage tank 3, an air compressor station 4, a PLC control module 5, a differential pressure transmitter 6, a first air control shut-off valve 7, The second pneumatic shut-off valve 8 , the third pneumatic shut-off valve 9 , the fourth pneumatic shut-off valve 10 and the fifth pneumatic shut-off valve 11 . One end of the fifth air-operated shut-off valve 11 is connected to the equipment main body 12 through a vacuum pipeline, and the other end of the fifth air-operated shut-off valve 11 is connected to the vacuum buffer tank 1 through a vacuum pipeline, and the vacuum buffer tank 1 is also connected to a vacuum pump 2 . After the first air-controlled shut-off valve 7, the second air-controlled shut-off valve 8, the third air-controlled shut-off valve 9 and the fourth air-controlled shut-off valve 10 a...

Embodiment 2

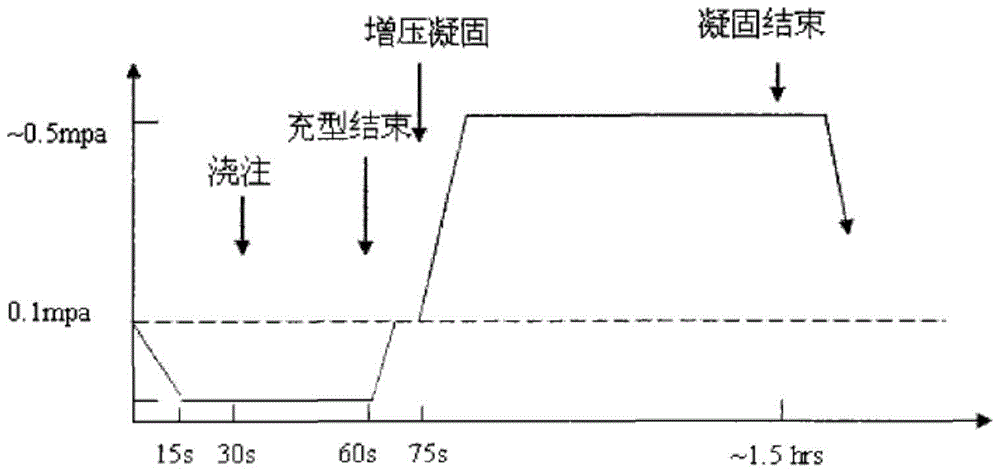

[0021]Example 2. A large-scale component is formed by gypsum-type precision casting method. After the degassing and refining treatment of molten metal is completed, the molten metal is put into the rotating ladle of the equipment main body 12, and then the baked large-scale plaster mold is sent into the equipment main body 12. Inside, and seal and lock the main body 12 of the device. Start the PLC control module 5, input process parameters: pouring vacuum degree 0.002MPa, pouring time 30 seconds, vacuum breaking time 5 seconds, holding time under normal pressure 3 seconds, pressurized solidification speed 0.02MPa / s, pressurized pressure 0.5MPa, The holding time is 900 seconds. The PLC control module 5 outputs control signals to open and close different air-operated stop valves according to the set process parameters, so as to realize real-time control of the pressure difference in the main body 12 of the equipment. When pouring starts, open the fifth air-controlled stop valv...

Embodiment 3

[0022] Example 3. A large-scale component is formed by gypsum-type precision casting method. After the degassing and refining treatment of molten metal is completed, the molten metal is put into the rotating ladle of the equipment main body 12, and then the baked large-scale plaster mold is sent into the equipment main body 12. Inside, and seal and lock the main body 12 of the device. Start the PLC control module 5, input process parameters: pouring vacuum degree 0.002MPa, pouring time 35 seconds, vacuum breaking time 8 seconds, holding time under normal pressure 4 seconds, pressurized solidification speed 0.025MPa / s, pressurized pressure 0.5MPa, The holding time is 3000 seconds. The PLC control module 5 outputs control signals to open and close different air-operated stop valves according to the set process parameters, so as to realize real-time control of the pressure difference in the main body 12 of the equipment. When pouring starts, open the fifth air-controlled stop v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com