End hole machining device with prepressing function for diesel engine cylinder

A diesel engine, pre-compression technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low processing efficiency, easy drilling deviation, low processing accuracy, etc., to improve processing efficiency and avoid drill bits. The effect of long and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the technical solution of the present invention will be described in detail through specific examples.

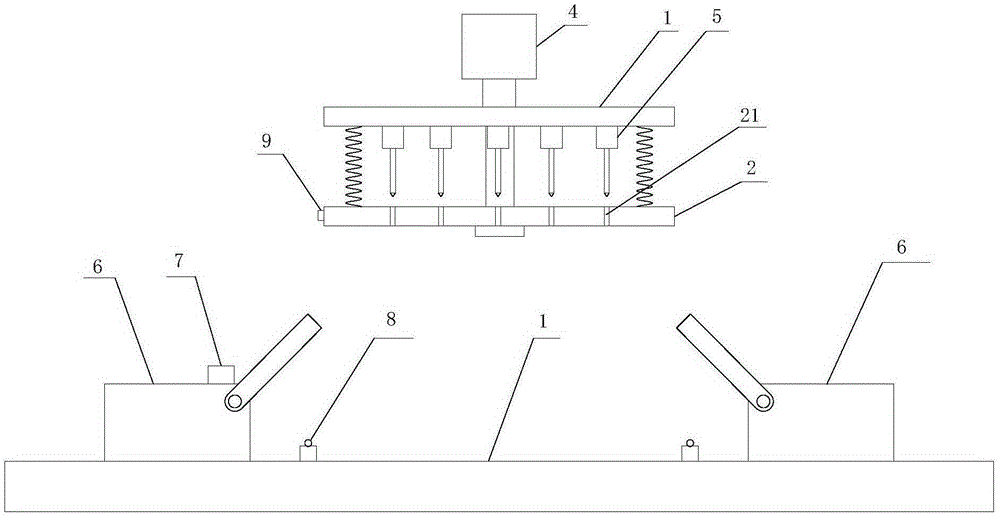

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a diesel engine cylinder end hole processing device with a pre-compression function proposed by the present invention.

[0019] refer to figure 1 , a diesel engine cylinder end hole processing device with pre-compression function proposed by the embodiment of the present invention, including: a fixed plate 1, a pre-compression plate 2, a workbench 3, a driving mechanism 4, a first sensor 7, and a second sensor 8 , the third sensor 9 and manipulator (not shown in the figure), wherein:

[0020] The fixed plate 1 is used to install the drilling mechanism 5. The fixed plate 1 is located above the workbench 3 and is driven by the driving mechanism 4 for lifting action. The drilling mechanism 5 with the same number of holes, and the drill bit in each drilling mechanism 5 faces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com