Electronic product shell and surface treatment method thereof

A surface treatment technology for electronic products, applied in the process of producing decorative surface effects, electrical equipment shells/cabinets/drawers, electrical components, etc., can solve the problem of inability to form gradient colors on the surface of the shell, single color on the surface of the shell, etc. problems, to achieve the effect of low cost, simple operation and less process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for surface treatment of an electronic product housing, comprising the steps of:

[0030] 1) Spray primer on the surface of the shell; the primer is UV transparent paint (Ultraviolet Curing Paint, called UV curing paint), the thickness of the primer is 25-30um, the baking temperature is 55±5°, and the UV paint baking energy is 600 -800mj / cm2.

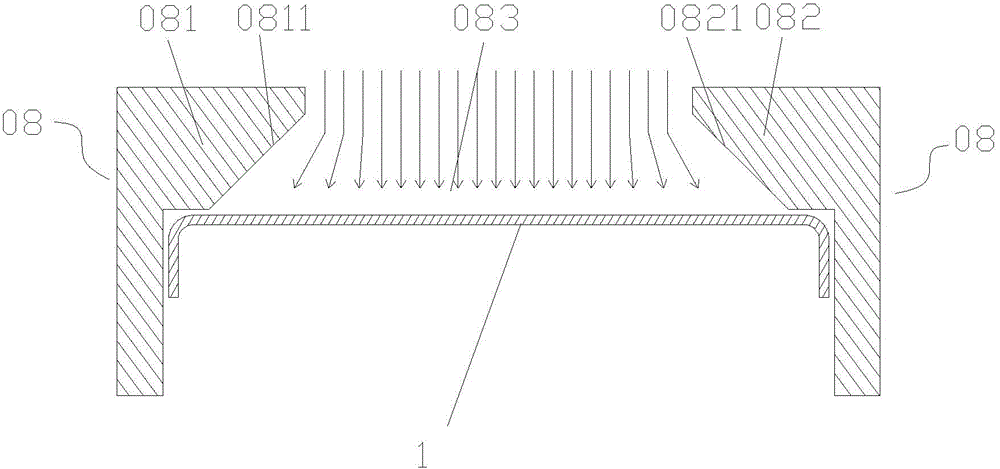

[0031] 2) Forming a metal coating on the primer by vacuum coating; the vacuum coating adopts NCVM process (Nonconductive vacuum metallization, called non-conductive vacuum electroplating). The vacuum coating is to dissolve the target material to be plated by direct heating or indirect heating under vacuum conditions, and then evaporate, or directly sublimate from a solid to a gas, and the atoms or molecules with sufficient energy fly to and deposit on the bottom. Deposit a certain thickness of metal film layer on the paint surface.

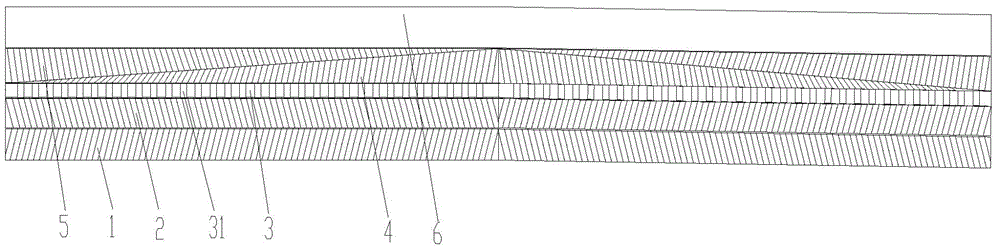

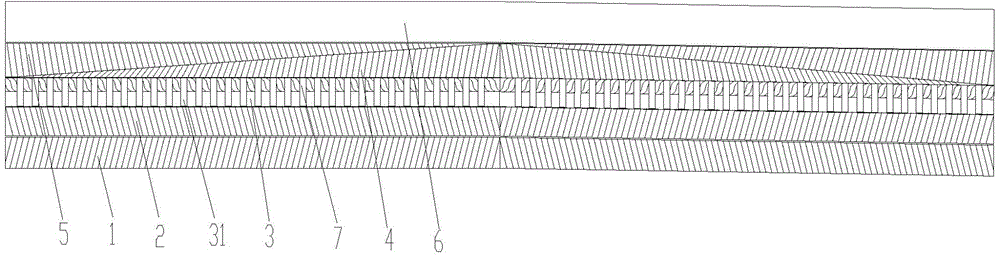

[0032] 3) Form the texture on the metal coating by laser engraving;

[0033] 4) Spray...

Embodiment 2

[0041] A method for surface treatment of an electronic product housing, comprising the steps of:

[0042] 1) Spray primer on the surface of the shell; the primer is UV transparent paint, the thickness of the primer is 25-30um, the baking temperature is 55±5°, and the baking energy of the UV paint is 600-800mj / cm2.

[0043] 2) forming a metal coating on the primer by vacuum coating; the vacuum coating adopts NCVM process. The vacuum coating is to dissolve the target material to be plated by direct heating or indirect heating under vacuum conditions, and then evaporate, or directly sublimate from a solid to a gas, and the atoms or molecules with sufficient energy fly to and deposit on the bottom. Deposit a certain thickness of metal film layer on the paint surface.

[0044] 3) Spraying an intermediate paint on the metal coating, the intermediate paint is a UV transparent paint, the thickness of the intermediate paint is 3-5um, the baking temperature is 55±5°, and the baking ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com