Blister packaging machine

A technology for a blister packaging machine and a driving device, which is used in packaging, packaging protection, transportation and packaging, etc., can solve the problems of complex and tedious adjustment work, high requirements for the quality of adjustment personnel, waste of packaging materials, energy consumption and time, etc. , to achieve the effect of reasonable overall design, reducing labor and saving consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

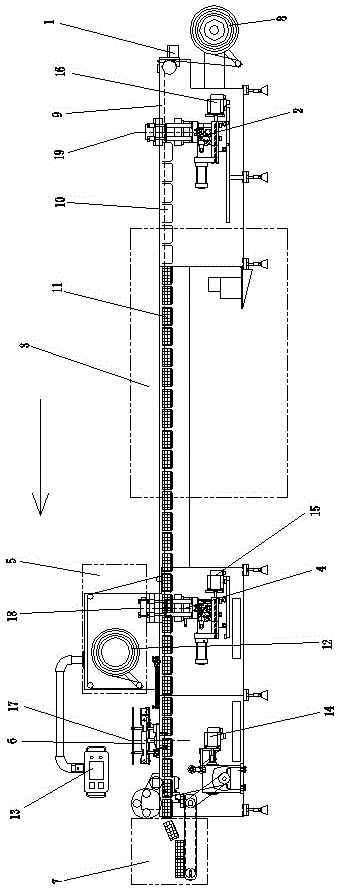

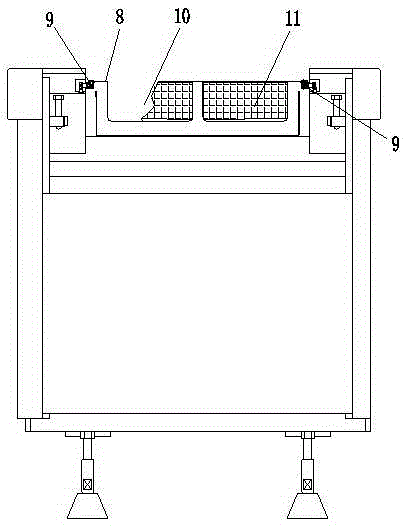

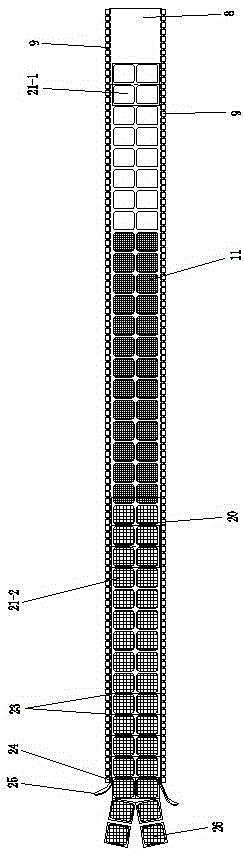

[0058] see Figure 1 to Figure 8 , The blister packaging machine of the embodiment of the present invention comprises a base film feeding mechanism 1, a forming mechanism 2, a sealing mechanism 4, a cutting mechanism 6, a clip chain 9, a clip chain driving device 14, a bottom film feeding mechanism 1, and a forming mechanism 2 , sealing mechanism 4, and cutting mechanism 6 are arranged in sequence, and the improved design includes electrical control device 13, forming mechanism driving device 16, sealing mechanism driving device 15, blade displacement driving device, and cutting mechanism 4 is provided with blade displacement driving device, blade The displacement driving device is connected with the cross-cutting blade 23, and the electric control device 13 is connected with the forming mechanism driving device 16, the sealing mechanism driving device 15, and the blade displacement driving device. First fix the position of one of the three mechanisms of the forming mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com