Integrated production system for high-grade highly-flavored type camellia oil

A production system and technology of tea seed oil, applied in the direction of fat oil/fat production, production of fat, edible oil/fat, etc., can solve the problem of rough processing, loss of characteristics and flavor of tea seed oil, acid value, color that does not meet national standards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

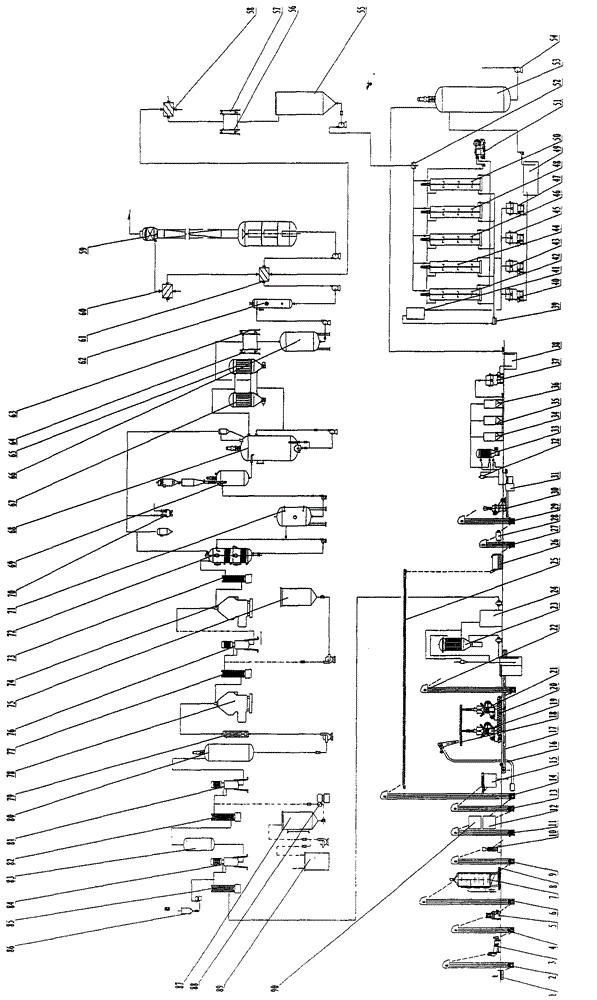

[0038] like figure 1 As shown, the complete production system of high-grade Luzhou-flavored tea seed oil is composed of pre-pressing equipment, refining equipment, winterization equipment and blending equipment. The pre-pressing equipment is divided into two groups, one group of equipment presses "intermediate oil 1" with 12-15% of the total oil after selection, and the other group of equipment presses "intermediate oil 2" with 82-85% of the total oil after selection. After the tea seed oil passes through the feeding pot 1, it is transported to the cleaning screen 3 by the No. 1 elevator 2 to remove large particles of impurities; after the impurities of the tea seed oil are removed, it is transported to the stone removal machine 5 by the No. stones, so as not to damage the follow-up equipment by stones and hard objects. After removing stones and sundries, the oil is transported to the flat dryer 7 by the No. 3 hoist 6 to dry the water; the oil is dried to a moderate level, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com