Preparation method of phosphatidylserine

A technology of phosphatidylserine and serine, applied in the direction of fermentation, etc., can solve problems such as difficulty in guarantee, large investment in equipment, purity of organic solvent residual products, etc., and achieve the effect of overcoming the complexity of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

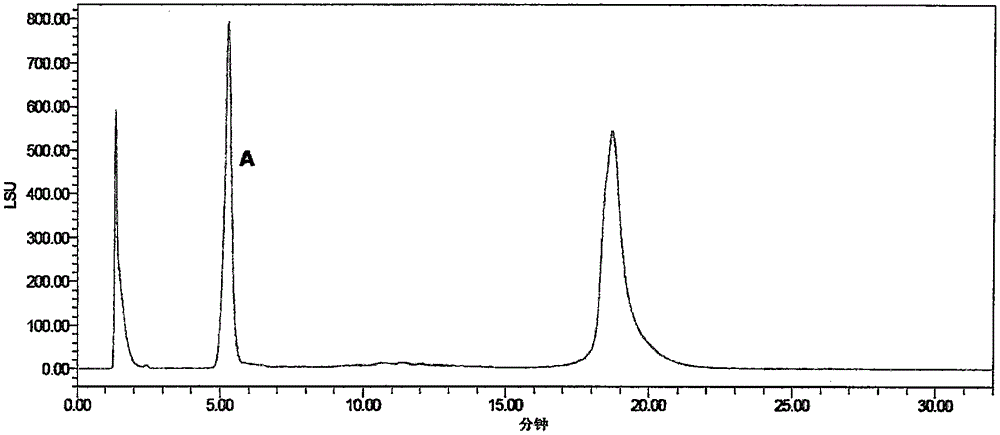

Embodiment 1

[0023] Weigh 80g of sodium acetate and dissolve it in 1L of water, add acetic acid to adjust the pH value to 5.5; then weigh 5.5g of CaCl 2 Dissolve in 250mL water, finally stir in 1L acetate buffer, 250mL calcium chloride solution, 120g soybean lecithin (phosphatidylcholine content 62.35wt%), 500gL-serine and 3L phospholipase D enzyme solution, heating temperature is 45 ℃, after reacting for 24 hours, filter, and wash the filter residue twice with 1.6L ethanol solution with a concentration of 95% by volume. The detected content was 72.01wt%, and the yield was 62.56wt%.

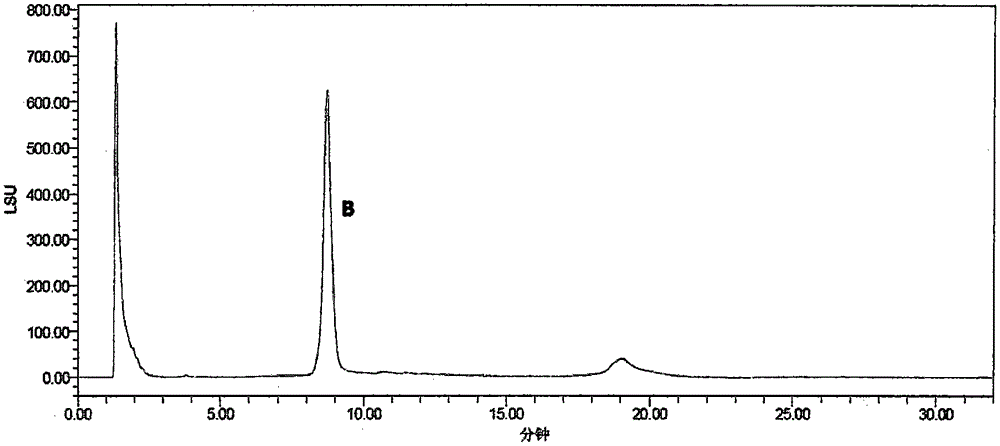

Embodiment 2

[0025] Weigh 80g of sodium acetate and dissolve it in 1L of water, add acetic acid to adjust the pH value to 5.5; then weigh 5.5g of CaCl 2 Dissolve in 250mL water, finally stir in 1L acetate buffer, 250mL calcium chloride solution, 120g soybean lecithin (phosphatidylcholine content 78.22wt%), 500gL-serine and 3L phospholipase D enzyme solution, heating temperature is 45 ℃, after reacting for 24 hours, filter, and wash the filter residue twice with 1.6L ethanol solution with a concentration of 95% by volume. The detected content was 76.02wt%, and the yield was 68.44wt%.

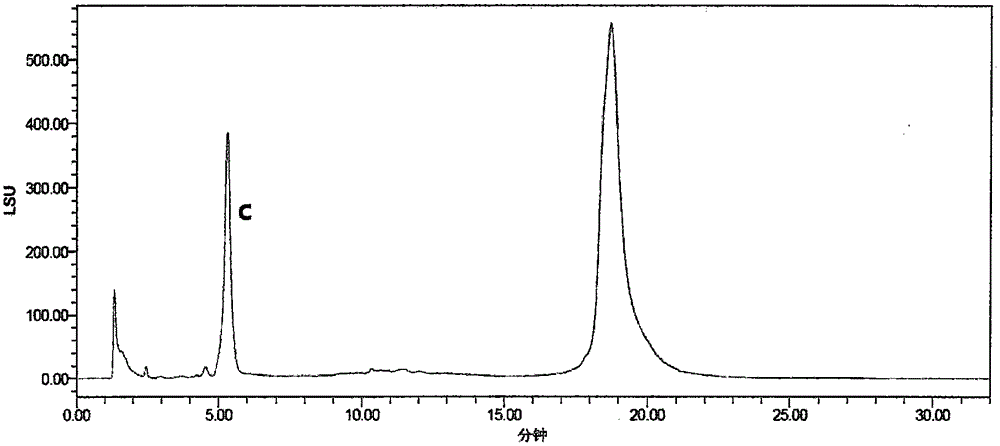

Embodiment 3

[0027] Weigh 80g of sodium acetate and dissolve it in 1L of water, add acetic acid to adjust the pH value to 5.5; then weigh 5.5g of CaCl 2 Dissolve in 250mL water, finally stir in 1L acetate buffer, 250mL calcium chloride solution, 120g soybean lecithin (phosphatidylcholine content 88.51wt%), 500gL-serine and 3L phospholipase D enzyme solution, heating temperature is 45 ℃, after reacting for 24 hours, filter, and wash the filter residue twice with 1.6L ethanol solution with a concentration of 95% by volume. The detected content was 79.83wt%, and the yield was 74.31wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com