Preparation method for L-selenocysteine

A technology of selenocysteine and selenocysteine, which is applied in the field of synthesis of L-selenocysteine, can solve the problem that L-selenocysteine is expensive in raw materials, low in process yield, and in production The problem of high cost, to achieve the effect of increased yield, simple method operation, easy purchase and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of L-selenocysteine using L-serine hydrochloride

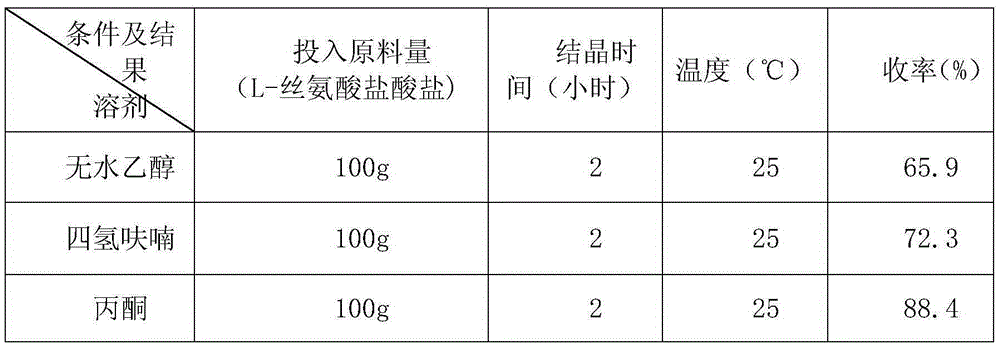

[0023] 1, Preparation of 3-chloro-L-alanine hydrochloride

[0024] Suspend L-serine hydrochloride (100g, 0.7067mol) in 500ml tetrahydrofuran, slowly add thionyl chloride (101g, 0.8480mol) dropwise, control the system <50°C during the dropwise addition, and slowly raise the temperature after the dropwise addition The reaction was stirred at 50°C for 6 hours. After the raw materials disappeared, the system was lowered to 20-25°C, and 50ml of water was slowly added dropwise to quench the reaction. Then it was concentrated to dryness under reduced pressure, 200ml of acetone was added while it was hot, cooled to 25°C to crystallize, filtered and dried to obtain 100g of off-white solid, Yield=88.4%.

[0025] 2. Preparation of L-selenocysteine

[0026] 2.1. Preparation of sodium selenite solution

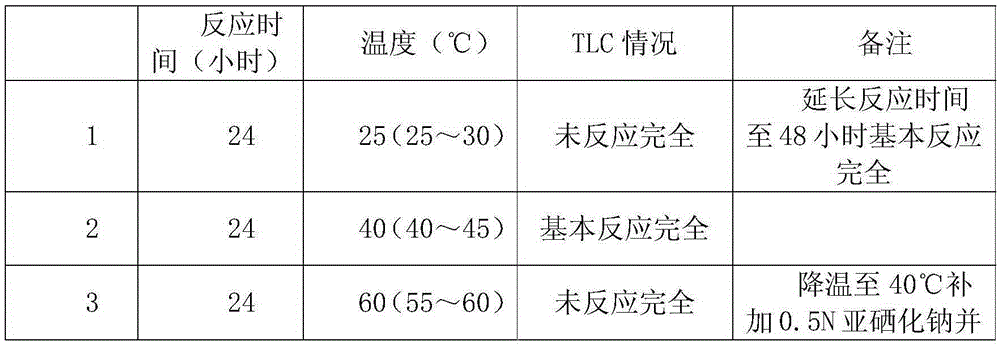

[0027] Suspend 100g selenium powder in 300ml water, add 50gNaBH in batches under stirring , control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com