Compound type wooden trestle and paving method thereof

A technology of composite wood and plank roads, which is applied in the construction of roads, roads, bridges, etc., can solve problems such as unsatisfactory anti-skid effects, achieve high maintenance costs, reduce accidents, and be easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

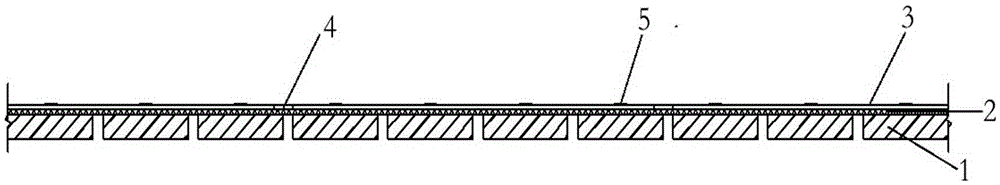

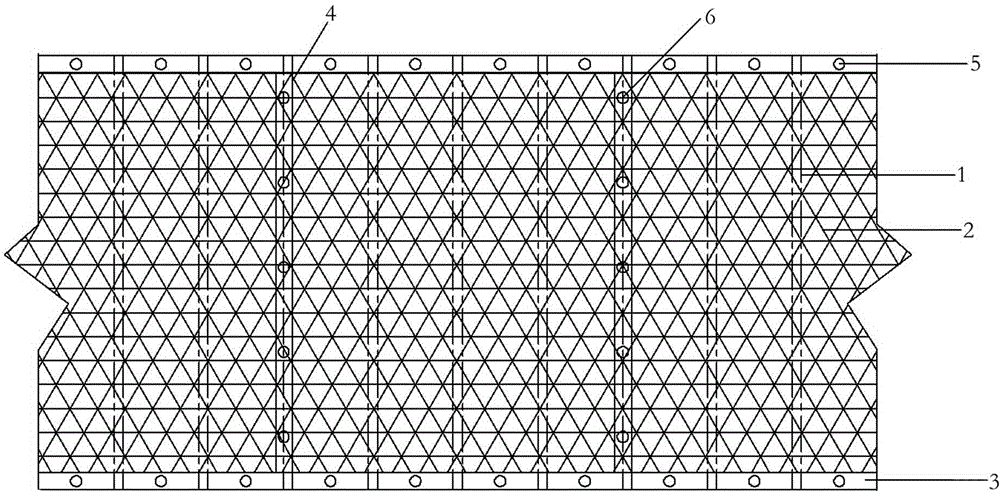

[0034] Such as Figure 1-3 As shown, a composite wooden plank road, the bottom layer of the wooden plank road is composed of a plurality of wooden boards 1 arranged in parallel and spaced apart. A wire mesh 2 is evenly laid on the top plane of the plank road. In this embodiment, the wire mesh 2 is made of steel wire, and the outer layer of the wire mesh 2 is coated with an antirust material coating. A vertical fixing plate 3 is arranged on the upper surface of the screen 2 in a flat manner, and the vertical fixing plate 3 is crimped on the screen 2 and fixed by a connecting member 5 . Specifically, two longitudinal fixing plates 3 are respectively placed on both ends of the wooden board 1 to contact the wire mesh 2 . In other words, the longitudinal fixing board 3 is fixedly connected to the wooden board 1 through a plurality of uniformly arranged connecting parts 5 thereon. In this embodiment, the longitudinal direction in the longitudinal fixing plate 3 refers to the walk...

Embodiment 2

[0037] Such as Figure 1-3 As shown, it includes a plank road composed of a plurality of planks 1 arranged at intervals horizontally in sequence, and a wire mesh 2 is laid on the top plane of the plank road. Fixed, the longitudinal fixed plate 3 is fixedly connected with the wooden board 1 through a plurality of connecting parts 5 thereon; a plurality of transverse crimping strips 4 are arranged at intervals on the upper surface of the screen 2, and the transverse crimping strips 4 is fixedly connected to the wooden board 1 through a plurality of connecting pieces 6 thereon, and the horizontal crimping strip 4 is in contact with the silk screen 2 . In this embodiment, both the connecting part 5 and the connecting piece 6 are rivets.

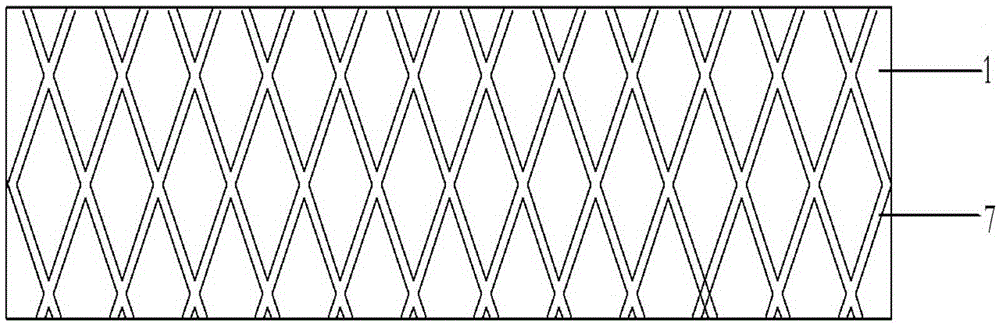

[0038] In this embodiment, the wire mesh 2 is woven with steel wires to form a steel wire mesh, the surface of the steel wires on the steel wire mesh has micro-grooves 7 and the steel wire mesh has been galvanized. The arrangement of the micro-...

Embodiment 3

[0040] Such as Figure 1-3 As shown, a composite wooden plank road, the bottom layer of the wooden plank road is composed of a plurality of wooden boards 1 arranged in parallel and spaced apart. A wire mesh 2 is evenly laid on the top plane of the plank road. In this embodiment, the wire mesh 2 is made of iron wire, and the outer layer of the wire mesh 2 is coated with an anti-rust material coating. A vertical fixing plate 3 is arranged on the upper surface of the screen 2 in a flat manner, and the vertical fixing plate 3 is crimped on the screen 2 and fixed by a connecting member 5 . Specifically, two longitudinal fixing plates 3 are respectively placed on both ends of the wooden board 1 to contact the wire mesh 2 . In other words, the longitudinal fixing board 3 is fixedly connected to the wooden board 1 through a plurality of uniformly arranged connecting parts 5 thereon. In this embodiment, the longitudinal direction in the longitudinal fixing plate 3 refers to the walk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com