Gas cutting early stage monitoring method

A technology of gas intrusion and monitoring device, which is applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of rapid determination and control of unfavorable gas intrusion, not belonging to early monitoring, and large limitations, and is easy to popularize. Use, reduce production costs, increase the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

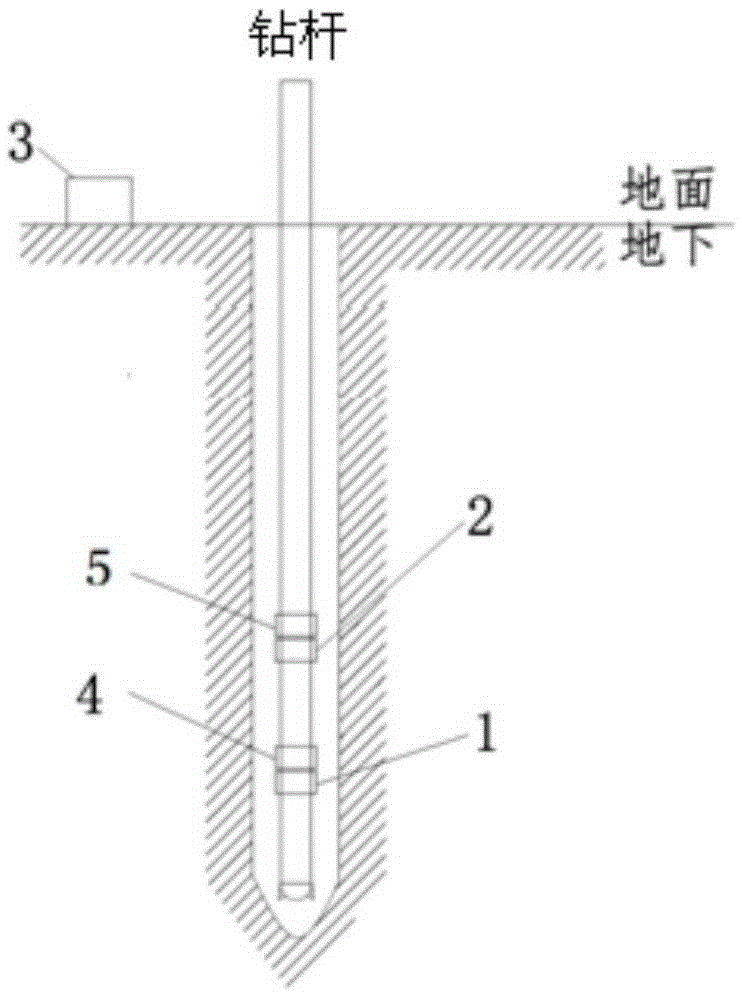

[0011] The gas intrusion early monitoring method involved in this embodiment is implemented using a gas intrusion early monitoring device. The lower pressure measuring device 1 and the short-distance wireless signal transmitter 4 and the upper pressure measuring device 2 are respectively installed on the downhole drill pipe according to the set spacing. And the downhole signal transmitter 5, the lower pressure measuring device 1 and the upper pressure measuring device 2 respectively measure the annulus fluid pressure at the location, and the short-distance wireless signal transmitter 4 measures the annulus fluid pressure at the location of the lower pressure measuring device 1. Transmitted to the upper pressure measuring device 2, the upper pressure measuring device 2 calculates the pressure difference and density of the annular fluid pressure between the lower pressure measuring device 1 and the upper pressure measuring device 2, and the upper pressure measuring device 2 can jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com