Electric melting pad and method for connecting plastic pipelines or pipelines with pipeline end surfaces made from plastic by virtue of same

A technology of plastic pipes and connection methods, which is applied in the direction of pipe connection arrangement, pipe/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of many connection procedures, low construction efficiency and complex production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The electric heating melting pad of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

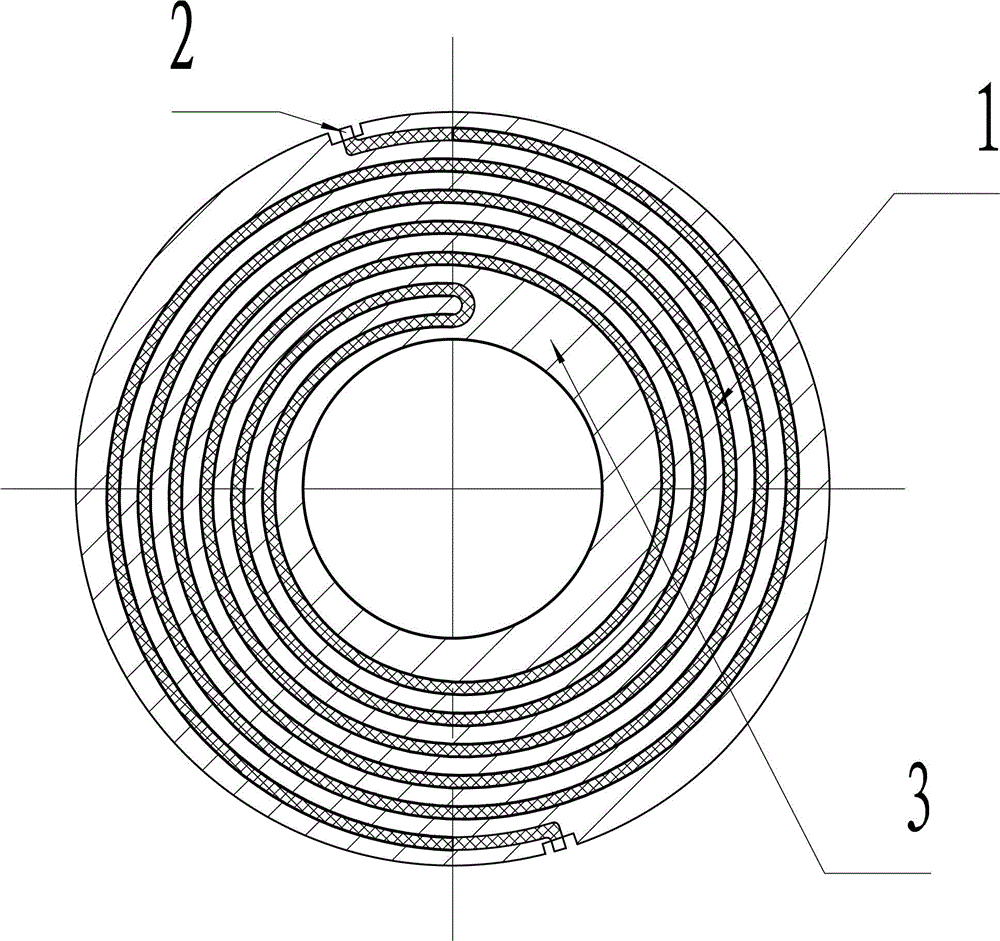

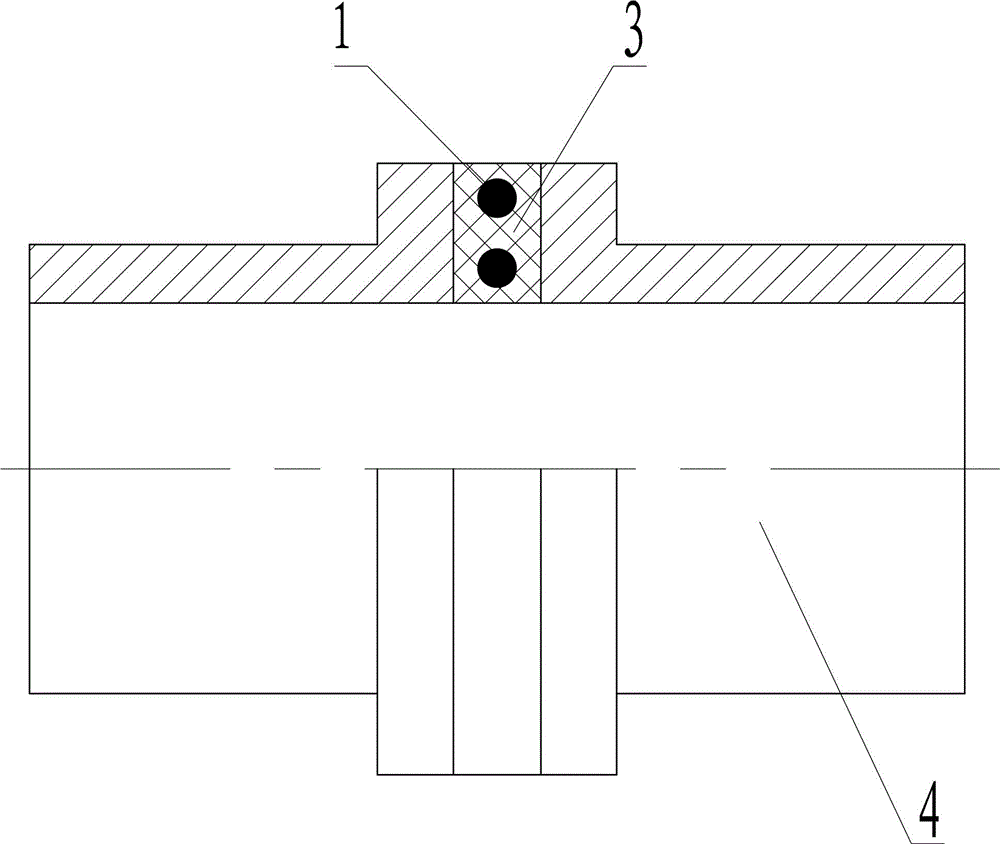

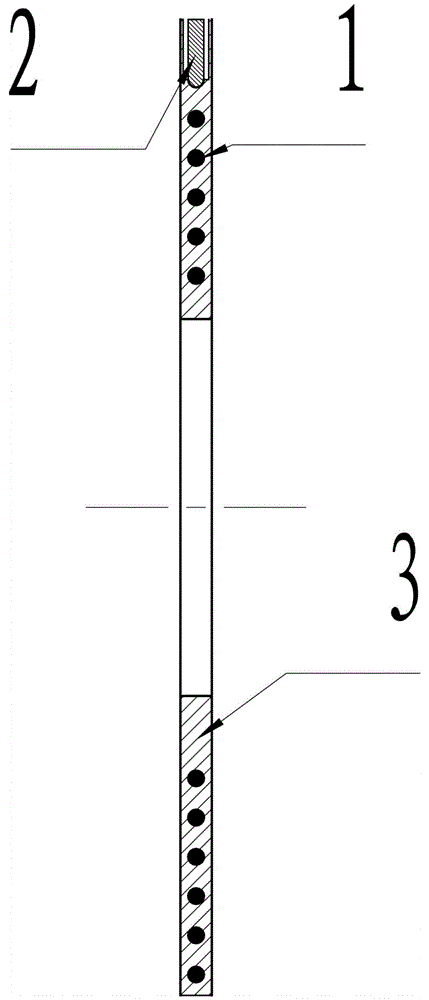

[0019] Such as figure 1 , 2 As shown, the electric heating melting pad includes a thermoplastic pad 3, a conductive resistance wire 1 embedded in the thermoplastic pad 3 and distributed in the form of an Archimedes double helix, and two conductive electrodes 2 connected to the conductive resistance wire 1, The conductive electrodes 2 are arranged in grooves on the outer surface of the thermoplastic pad 3 .

[0020] Wherein the conductive resistance wire 1 is inlaid (or embedded) in the thermoplastic pad 3 according to the Archimedes double helix distribution. To prevent the distance from being too short, the conductive resistance wire 1 is exposed outside the thermoplastic pad 3 after being heated during the welding process, causing leakage. At the same time, the distance between the conductive resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com