Compound intensified heat transfer pipe with internally installed twisting belts

A technology of heat transfer tubes and twisted bands, which is applied in the field of composite enhanced heat transfer tubes, can solve the problems of low comprehensive heat transfer performance, single twisted band structure, and lower than 1 comprehensive heat transfer performance, so as to increase the heat transfer rate of the tube wall , flow field homogenization, and the effect of increasing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

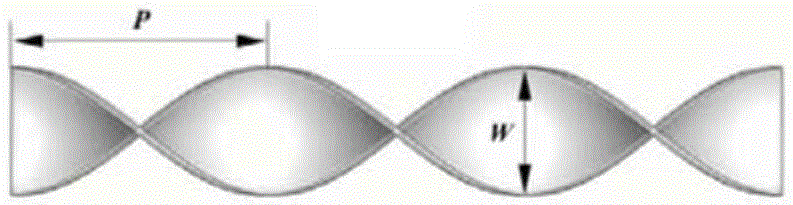

[0056] as attached Figure 5~8 As shown, the outer diameter of the composite enhanced heat transfer tube with a built-in twisted band is less than 20 mm, the tube body is a positive (cos) stringed tube, and the rib pitch of the positive (cos) stringed tube is L =20mm, rib amplitude A =12mm, the number of circumferential ribs n =4, outer diameter d =19mm, wall thickness t =2mm, rib height e =1.1mm, there is a single-twisted belt inside, the torsion rate of the twisted belt is y=2.67, half pitch P =32mm, pitch C =64mm, the thickness of twisted strap B =1mm, width of twisted belt W =12mm.

Embodiment 2

[0058] as attached Figure 9~12 As shown, the outer diameter of the composite enhanced heat transfer tube with a built-in twisted band is between 20 and 50 mm, the tube body is a positive (cos) stringed tube, and the rib pitch of the positive (cos) stringed tube is L =30mm, rib amplitude A =16mm, the number of circumferential ribs n =8, outer diameter d =32mm, wall thickness t =3mm, rib height e =0.8mm; there are double twisted bands inside the tube body, and the double twisted bands have opposite directions of rotation, that is, one twisted band rotates clockwise around the central axis, and the other twisted band rotates counterclockwise around the central axis, which is conducive to improving the eddy current intensity . The torsion rate of the twisted ribbon y =2.87, half pitch P =33mm, pitch C =66mm, the thickness of twisted strap B =1mm, width of twisted belt W =11.5mm.

Embodiment 3

[0060] as attached Figure 13~16 As shown, the outer diameter of the composite enhanced heat transfer tube with a built-in twisted band is between 20 and 50 mm, the tube body is a positive (cos) stringed tube, and the rib pitch of the positive (cos) stringed tube is L =20mm, rib amplitude A =12mm, the number of circumferential ribs n =6, outer diameter d =32mm, wall thickness t =3mm, rib height e =1.1mm; there is a double twisted belt inside the tube body, and the direction of rotation of the double twisted belt is opposite, which is conducive to improving the eddy current strength; the twist rate of the twisted belt y =2.09, half pitch P =24mm, pitch C =48mm, the thickness of twisted belt B =1mm, width of twisted belt W =11.5mm. In turbulent flow, the heat transfer rate relative to the light pipe can be increased by more than 2 times at most, and the comprehensive heat transfer performance can reach more than 1.1 under the same power consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com